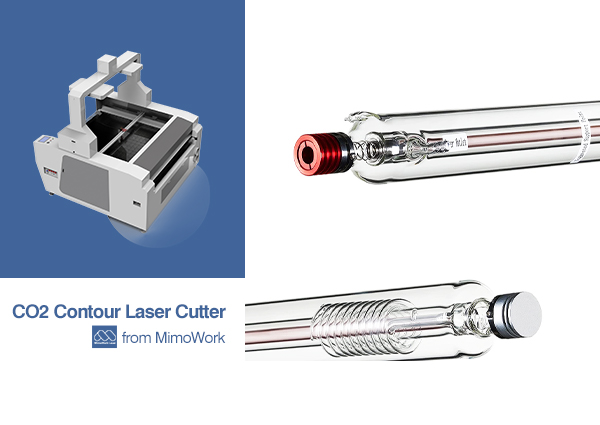

CO2 laser tube, especially the CO2 glass laser tube, is widely used in laser cutting and engraving machines. It is the core component of the laser machine, responsible for producing the laser beam.

In general, the lifespan of a CO2 glass laser tube ranges from 1,000 to 3,000 hours, depending on the tube quality, usage conditions, and power settings.

Over time, the laser power may weaken, leading to inconsistent cutting or engraving results. This is when you need to replace your laser tube.

Step 1: Power Off and Disconnect

Before attempting any maintenance, ensure your laser machine is completely powered off and unplugged from the electrical outlet. This is important for your safety, as laser machines carry high voltages that could cause injury.

Additionally, wait for the machine to cool down if it was recently in use.

Step 2: Drain the Water Cooling System

CO2 glass laser tubes use a water cooling system to prevent overheating during operation.

Before removing the old tube, disconnect the water inlet and outlet hoses and allow the water to drain completely. Draining the water prevents spills or damage to electrical components when you remove the tube.

One Tip:

Make sure the cooling water you use is free of minerals or contaminants. Using distilled water helps avoid scale build-up inside the laser tube.

Step 3: Remove the Old Tube

• Disconnect the electrical wiring: Carefully detach the high-voltage wire and the ground wire connected to the laser tube. Pay attention to how these wires are connected, so you can reattach them to the new tube later.

• Loosen the clamps: The tube is typically held in place by clamps or brackets. Loosen these to free the tube from the machine. Handle the tube with care, as the glass is fragile and can break easily.

Step 4: Install the New Tube

• Position the new laser tube: Place the new tube into the same position as the old one, ensuring that it is aligned properly with the laser optics. Misalignment can result in poor cutting or engraving performance and may damage the mirrors or lens.

• Secure the tube: Tighten the clamps or brackets to hold the tube securely in place, but do not over-tighten, as this can crack the glass.

Step 5: Reconnect the Wiring and Cooling Hoses

• Reattach the high-voltage wire and ground wire to the new laser tube. Ensure the connections are tight and secure.

• Reconnect the water inlet and outlet hoses to the cooling ports on the laser tube. Ensure the hoses are fitted tightly and there are no leaks. Proper cooling is critical to avoid overheating and extending the tube’s lifespan.

Step 6: Check the Alignment

After installing the new tube, check the laser’s alignment to make sure the beam is properly focused through the mirrors and lens.

Misaligned beams can lead to uneven cuts, loss of power, and damage to the laser optics.

Adjust the mirrors as needed to ensure the laser beam travels correctly.

Step 7: Test the New Tube

Power on the machine and test the new tube at a low power setting.

Perform a few test cuts or engravings to ensure everything is working correctly.

Monitor the cooling system to ensure there are no leaks and the water is flowing properly through the tube.

One Tip:

Gradually increase the power to test the tube’s full range and performance.

Video Demo: CO2 Laser Tube Installation

You should replace the CO2 glass laser tube when you notice specific signs indicating that its performance is declining or it has reached the end of its lifespan. Here are the key indicators that it’s time to replace the laser tube:

Sign 1: Decreased Cutting Power

One of the most noticeable signs is a reduction in cutting or engraving power. If your laser is struggling to cut through materials that it previously handled with ease, even after increasing the power settings, it’s a strong indicator that the laser tube is losing efficiency.

Sign 2: Slower Processing Speeds

As the laser tube degrades, the speed at which it can cut or engrave will decrease. If you notice that jobs are taking longer than usual or require multiple passes to achieve the desired result, it’s a sign that the tube is nearing the end of its service life.

Sign 3: Inconsistent or Poor Quality Output

You may start noticing poor-quality cuts, including rough edges, incomplete cuts, or less precise engraving. If the laser beam becomes less focused and consistent, the tube might be degrading internally, affecting beam quality.

Sign 4. Physical Damage

Cracks in the glass tube, leaks in the cooling system, or any visible damage to the tube are immediate reasons for replacement. Physical damage not only affects the performance but could also cause the machine to malfunction or fail completely.

Sign 5: Reaching the Expected Lifespan

If your laser tube has been used for 1,000 to 3,000 hours, depending on its quality, it’s likely nearing the end of its lifespan. Even if performance hasn’t significantly declined yet, proactively replacing the tube around this time can prevent unexpected downtime.

By paying attention to these indicators, you can replace your CO2 glass laser tube at the right time, maintaining optimal performance and avoiding more serious machine issues.

3. Buying Advice: Laser Machine

If you have been using a CO2 laser machine for your production, these tips and tricks about how to take care of your laser tube are helpful to you.

If you are still not sure how to select a laser machine and have no idea of what machine types are there. Check out the following advice.

About CO2 Laser Tube

There are two types of CO2 laser tubes: RF laser tubes and glass laser tubes.

RF laser tubes are more sturdy and durable in working performance, but more expensive.

Glass laser tubes are common options for most, cause the great balance between cost and performance. But a glass laser tube requires more care and maintenance, so when using the glass laser tube, you need to check it regularly.

We suggest you select the well-regarded brands of laser tubes, such as RECI, Coherent, YongLi, SPF, SP, etc.

About CO2 Laser Machine

CO2 Laser Machine is the popular option for non-metal cutting, engraving, and marking. With the development of laser technology, CO2 laser processing has been gradually more mature and advanced. There are many laser machine suppliers and service providers, but the quality of machines and service assurance varies, some are good, and some are bad.

How to choose a reliable machine supplier among them?

1. Self-Developed and Produced

Whether a company has its factory or core technical team is significant, which determines the machine quality and professional guidance to clients from pre-sales consultation to after-sale guarantee.

2. Fame from Client Reference

You can send an email to inquire about their client reference, including clients' locations, machine-using conditions, industries, etc. If you are close to one of the clients, visit or call to learn more about the supplier.

3. Laser Test

The most direct method to find out whether it's good at laser technology, send your material to them and ask for a laser test. You can check out the cutting condition and effect via video or picture.

4. Accessibility

Whether the laser machine supplier has its own website, social media accounts such as YouTube Channel, and freight forwarder with long-term cooperation, check these out, to evaluate whether to choose the company.

Your Machine Deserves the Best !

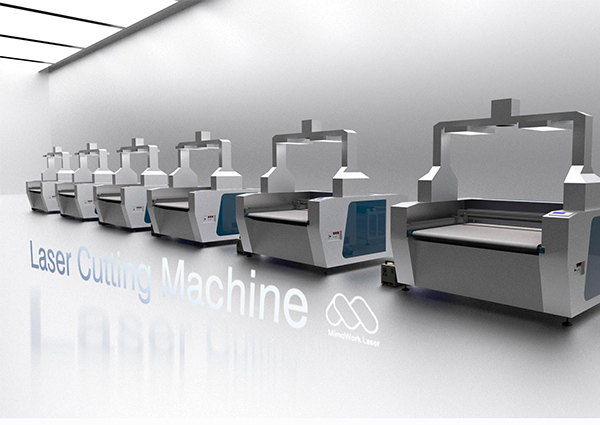

Who Are We? MimoWork Laser

A professional laser machine manufacturer in China. We offer customized laser solutions for every client in various industries from textile, apparel, and advertising, to automotive and aviation.

Reliable Laser Machine and Professional Service and Guideness, Empowering Every Customer to Achieve Breakthroughs in Production.

We list some popular laser machine types you might interested in.

If you have a purchase plan for a laser machine, check them out.

Any questions about the laser machines and their functions, applications, configurations, options, etc. Contact us to discuss this with our laser expert.

• Laser Cutter and Engraver for Acrylic & Wood:

Perfect for those intricate engraving designs and precise cuts on both materials.

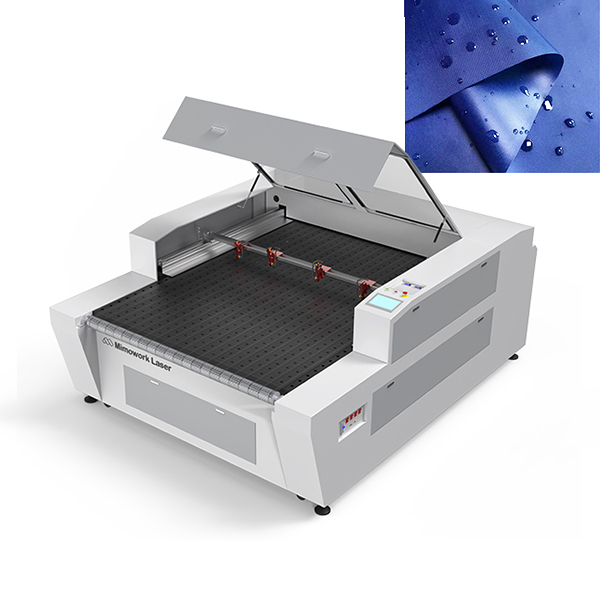

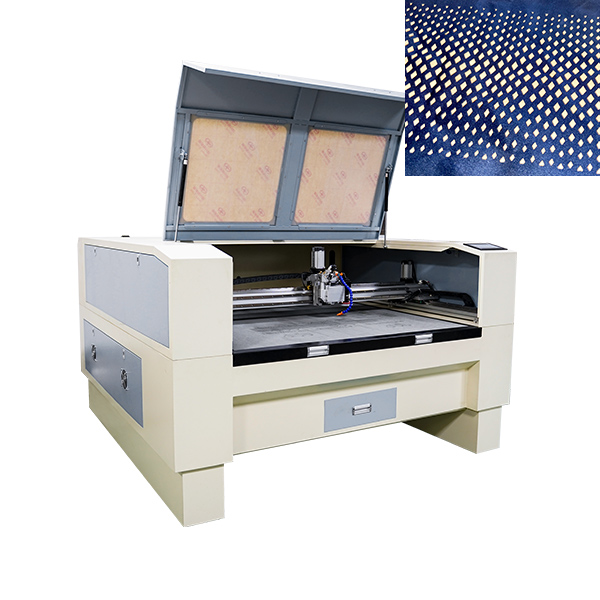

• Laser Cutting Machine for Fabric & Leather:

High automation, ideal for those working with textiles, ensuring smooth, clean cuts every time.

• Galvo Laser Marking Machine for Paper, Denim, Leather:

Fast, efficient, and perfect for high-volume production with custom engraving details and markings.

Learn More about Laser Cutting Machine, Laser Engraving Machine

Glance at the Our Machine Collection

You may be Interested

More Video Ideas >>

Laser Cut Acrylic Cake Topper

How to select laser cutting table?

Fabric Laser Cutter with Collection Area

We are a Professional Laser Cutting Machine Manufacturer,

What Your Concern, We Care!

Post time: Sep-06-2024