Foam is a versatile material widely utilized across numerous industries due to its varied applications. It plays a critical role in furniture, automotive, insulation, construction, packaging, and more.

The increasing adoption of lasers in manufacturing is attributed to their precision and efficiency in cutting materials. Foam, in particular, is a favored material for laser cutting, as it offers significant advantages over traditional methods.

This article delves into common foam types and their applications.

Introduction To Laser Cut Foam

▶ Can You Laser Cut Foam?

Yes, foam can be laser cut effectively. Laser cutting machines are commonly employed to cut various foam types with exceptional precision, speed, and minimal material waste. However, understanding the type of foam and adhering to safety guidelines are essential for achieving optimal results.

Foam, known for its versatility, finds applications in diverse industries such as packaging, upholstery, and model making. If a clean, efficient, and precise method is required to cut foam, comprehending the capabilities and limitations of laser cutting is crucial for informed decision-making.

▶ What Type Of Foam Can Your Laser Cut?

Laser cutting foam supports a variety of materials, ranging from soft to rigid. Each type of foam has unique properties that suit specific applications, simplifying the decision-making process for laser cutting projects. Below are the most popular types of foam for laser foam cutting:

1. Ethylene-Vinyl Acetate(EVA) Foam

EVA foam is a high-density, highly elastic material. It is ideal for interior design and wall insulation applications. EVA foam maintains its shape well and is easy to glue, making it an excellent choice for creative and decorative design projects. Laser foam cutters handle EVA foam with precision, ensuring clean edges and intricate patterns.

2. Polyethylene(PE) Foam

PE foam is a low-density material with good elasticity, making it perfect for packaging and shock absorption. Its lightweight nature is advantageous for reducing shipping costs. Additionally, PE foam is commonly laser cut for applications requiring high precision, such as gaskets and sealing components.

3. Polypropylene(PP) Foam

Known for its lightweight and moisture-resistant properties, polypropylene foam is widely used in the automotive industry for noise reduction and vibration control. Laser foam cutting ensures uniform results, crucial for the production of custom automotive parts.

4. Polyurethane(PU) Foam

Polyurethane foam is available in both flexible and rigid varieties and offers great versatility. Soft PU foam is used for car seats, while rigid PU is used as insulation in refrigerator walls. Custom PU foam insulation is commonly found in electronic enclosures to seal the sensitive components, prevent shock damage, and prevent water ingress.

▶ Is It Safe To Laser Cut Foam?

Safety is a primary concern when laser cutting foam or any material. Laser cutting foam is generally safe when the appropriate equipment is used, PVC foam is avoided, and adequate ventilation is maintained. Following the manufacturer's guidelines for specific foam types is critical.

Potential Hazards

• Toxic Emissions: Foams containing PVC may emit harmful gases like chlorine during cutting.

• Fire Risk: Incorrect laser settings can ignite foam. Ensure the machine is well-maintained and supervised during operation.

Tips For Safe Foam Laser Cutting

• Use only approved foam types for laser cutting.

• Wear protective safety glasses while operating the laser cutter.

• Regularly clean the optics and filters of the laser cutting machine.

Can You Laser Cut EVA Foam?

▶ What Is EVA Foam?

EVA foam, or Ethylene-Vinyl Acetate foam, is a synthetic material commonly used across various applications. It is produced by combining ethylene and vinyl acetate under controlled heat and pressure, resulting in a lightweight, durable, and flexible foam.

Known for its cushioning and shock-absorbing properties, EVA foam is a preferred choice for sports equipment, footwear, and crafting projects.

▶ Is It Safe to Laser-Cut EVA Foam?

EVA foam, or Ethylene-Vinyl Acetate foam, is a synthetic material commonly used across various applications.This process releases gases and particulate matter, including volatile

EVA Foam Application

organic compounds (VOCs) and combustion byproducts such as acetic acid and formaldehyde. These fumes can have a noticeable odor and may pose potential health risks if proper precautions are not taken.

It is important to have proper ventilation in place when laser cutting EVA foam to remove the fumes from the working area. Adequate ventilation helps maintain a safe working environment by preventing the accumulation of potentially harmful gases and minimizing the odor associated with the process.

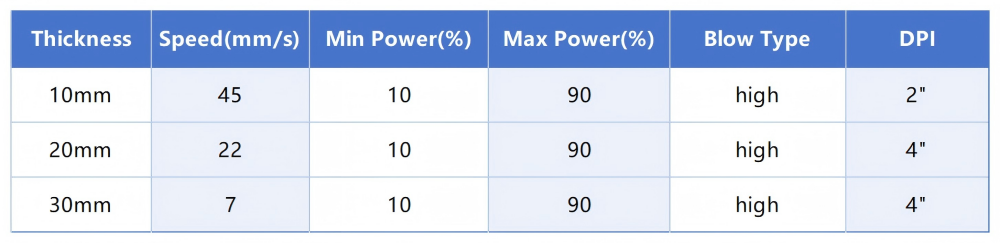

▶ Eva Foam Laser Cutting Settings

When laser cutting EVA foam, results may vary based on the foam’s origin, batch, and production method. While general parameters provide a starting point, fine-tuning is often required for optimal results. Here are some general parameters to get you started, but you may need to fine-tune them for your specific laser-cut foam project.

Any Questions About That?

Connect With Our Laser Expert !

Can You Laser Cut Foam Inserts?

Foam inserts are widely used for applications like protective packaging and tool organization. Laser cutting is an ideal method for creating precise, custom-fit designs for these inserts. CO2 lasers are particularly well-suited for cutting foam. Ensure that the foam type is compatible with laser cutting, and adjust power settings for accuracy.

▶ Applications for Laser-Cut Foam Inserts

Laser-cut foam inserts are beneficial in numerous contexts, including:

• Tool Storage: Custom-cut slots secure tools in place for easy access.

• Product Packaging: Provides protective cushioning for delicate or sensitive items.

• Medical Equipment Cases: Offers custom-fit compartments for medical instruments.

▶ How to Laser Cut Foam Inserts

▼

▼

▼

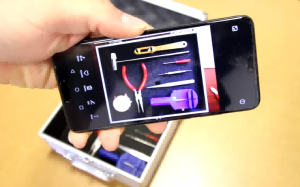

Step 1: Measure Tools

Begin by arranging the items inside their container to determine positioning.

Take a photo of the arrangement to use as a guide for cutting.

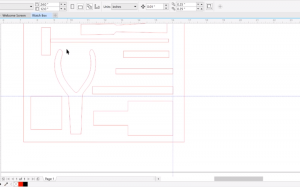

Step 2: Create the Graphic File

Import the photo into a design program. Resize the image to match the actual container dimensions.

Create a rectangle with the container’s dimensions and align the photo with it.

Trace around the objects to create cut lines. Optionally, include spaces for labels or easier object removal.

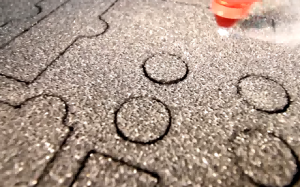

Step 3: Cut and Engrave

Place the foam in the laser cutting machine and send the job using the appropriate settings for the foam type.

Step 4: Assembly

After cutting, layer the foam as required. Insert the objects into their designated spots.

This method produces a professional display suitable for storing tools, instruments, awards, or promotional items.

Typical Applications of Laser Cut Foam

Foam is an exceptionally versatile material with applications spanning industrial and consumer sectors. Its lightweight nature and ease of cutting and shaping make it a preferred choice for prototypes and finished products alike. Additionally, foam’s insulating properties allow it to maintain temperatures, keeping products cool or warm as required. These qualities make foam an ideal material for a wide range of uses.

▶ Laser-cut Foam For Automotive Interiors

The automotive industry represents a significant market for foam applications. Automotive interiors represent a prime example of this, as foam can be utilized to enhance comfort, aesthetics, and safety. Additionally, sound absorption and insulation are crucial factors in automobiles. Foam can play an important role in all of these areas. Polyurethane(PU) foam, for instance, can be utilized to line the door panels and roof of a vehicle to enhance sound absorption. It can also be used in the seating area to provide comfort and support. Polyurethane (PU) foam's insulating properties contribute to maintaining a cool interior in summer and a warm interior in winter.

>> Check out the videos: Laser Cutting PU Foam

We Used

Material: Memory Foam (PU foam)

Material Thickness: 10mm, 20mm

Laser Machine: Foam Laser Cutter 130

You Can Make

Wide Application: Foam Core, Padding, Car Seat Cushion, Insulation, Acoustic Panel, Interior Decor, Crats, Toolbox and Insert, etc.

In the field of car seat padding, foam is often used to provide comfort and support. Additionally, foam's malleability allows for precise cutting with laser technology, enabling the creation of customized shapes to ensure a perfect fit. Lasers are precision tools, making them an ideal choice for this application due to their accuracy and efficiency. Another key benefit of using foam with a laser is the minimal wastage during the cutting process, which contributes to cost efficiency.

▶ Laser-cut Foam For Filters

Laser-cut foam is a popular choice in the filtration industry due to its numerous advantages over other materials. Its high porosity allows for excellent airflow, making it an ideal filter medium. Additionally, its high moisture absorption capacity makes it well-suited for use in humid environments.

Additionally, laser-cut foam is non-reactive and does not release harmful particles into the air, making it a safer option compared to other filter materials. These characteristics position laser-cut foam as a safe and environmentally friendly solution for various filtration applications. Finally, laser-cut foam is relatively inexpensive and easy to manufacture, making it an economical option for many filter applications.

▶Laser-cut Foam For Furniture

Laser-cut foam is a common material in the furniture industry, where its intricate and delicate designs are in high demand. The high precision of laser cutting allows for very precise cuts, which can be difficult or impossible to achieve with other methods. This makes it a popular choice for furniture manufacturers who want to create unique and eye-catching pieces. Additionally, laser-cut foam is frequently utilized as a cushioning material, offering comfort and support to furniture users.

Cut Seat Cushion with Foam Laser Cutter

The versatility of laser cutting allows for the creation of customized foam furniture, making it a valuable tool for businesses in the furniture and related industries. This trend is gaining popularity in the home decor industry and among businesses such as restaurants and hotels. The versatility of laser-cut foam allows for the creation of a wide range of furniture pieces, from seat cushions to tabletops, enabling customers to customize their furniture to suit their specific needs and preferences.

▶ Laser-cut Foam For Packaging

The foam can be processed to be laser cut tool foam or laser cut foam inserts for the packaging industry. These inserts and tool foam are precision-processed to fit the specific shape of instruments and fragile products. This ensures a precise fit for the items in the package. For instance, laser-cut tool foam can be utilized for packaging hardware tools. In the hardware manufacturing and laboratory instrument industries, the laser cut tool foam is particularly well-suited for packaging applications. The tool foam's precise contours align seamlessly with the tools' profiles, ensuring a snug fit and optimal protection during shipping.

Additionally, laser cut foam inserts are employed for cushion packaging of glass, ceramics, and household appliances. These inserts prevent collisions and ensure the integrity of fragile

products during transportation. These inserts are primarily used for packaging products such as jewelry, handicrafts, porcelain, and red wine.

▶ Laser-cut Foam For Footwear

Laser cut foam is commonly used in the footwear industry to create shoe soles. The laser-cut foam is durable and shock absorbent, making it a perfect material for shoe soles. Additionally, the laser-cut foam can be designed to have specific cushioning properties, depending on the needs of the customer. This makes it an ideal material for shoes that need to provide extra comfort or support. Thanks to its many benefits, laser-cut foam is quickly becoming a popular choice for shoe manufacturers worldwide.

Any Questions About How The Lase Cutting Foam Work, Contact Us!

Recommended Laser Foam Cutter

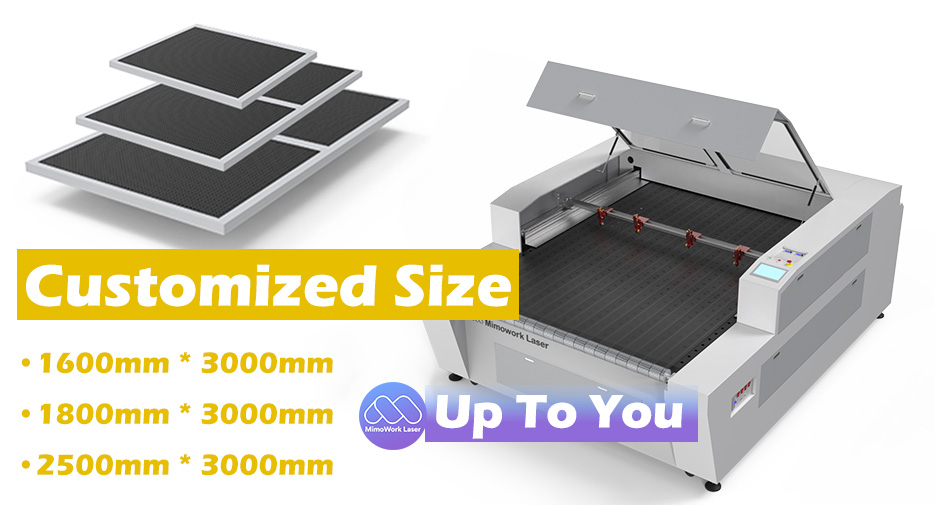

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

For regular foam products like toolboxs, decorations, and crafts, the Flatbed Laser Cutter 130 is the most popular choice for foam cutting and engraving. The size and power satisfy most requirements, and the price is affordable. Pass through design, upgraded camera system, optional working table, and more machine configurations you can choose.

Working Table Size: 1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 160

The Flatbed Laser Cutter 160 is a large-format machine. With the auto feeder and conveyor table, you can accomplish auto-processing roll materials. 1600mm *1000mm of working area is suitable for most yoga mat, marine mat, seat cushion, industrial gasket and more. Multiple laser heads are optional to enhance productivity.

FAQs of Laser Cutting Foam

▶ What Is The Best Laser To Cut Foam?

The CO2 laser is the most recommended and widely used for cutting foam due to its effectiveness, precision, and ability to produce clean cuts. With a wavelength of 10.6 micrometers, CO2 lasers are well-suited for foam materials, as most foams absorb this wavelength efficiently. This ensures excellent cutting results across a variety of foam types.

For engraving foam, CO2 lasers also excel, providing smooth and detailed results. While fiber and diode lasers can cut foam, they lack the versatility and cutting quality of CO2 lasers. Considering factors like cost-effectiveness, performance, and versatility, the CO2 laser is the top choice for foam cutting projects.

▶ Can You Laser Cut EVA Foam?

▶ What Materials Are Not Safe to Cut?

Yes, EVA (ethylene-vinyl acetate) foam is an excellent material for CO2 laser cutting. It is widely used in packaging, crafts, and cushioning. CO2 lasers cut EVA foam precisely, ensuring clean edges and intricate designs. Its affordability and availability make EVA foam a popular choice for laser cutting projects.

✖ PVC (emits chlorine gas)

✖ ABS (emits cyanide gas)

✖ Carbon fibers with a coating

✖ Laser light-reflective materials

✖ Polypropylene or polystyrene foam

✖ Fiberglass

✖ Milk bottle plastic

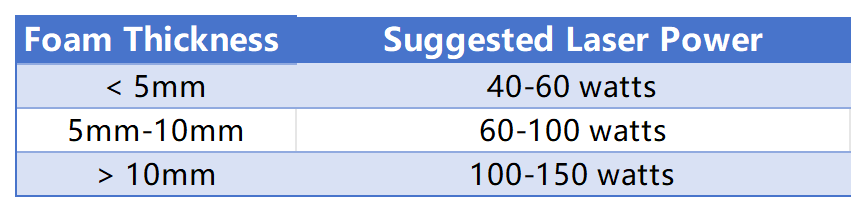

▶ What Power Laser Is Needed To Cut Foam?

The required laser power depends on the foam’s density and thickness.

A 40- to 150-watt CO2 laser is typically sufficient for cutting foam.Thinner foams may only need lower wattage, while thicker or denser foams may require more powerful lasers.

▶ Can You Laser Cut PVC Foam?

No, PVC foam should not be laser cut because it releases toxic chlorine gas when burned. This gas is harmful to both health and the laser machine. For projects involving PVC foam, consider alternative methods like a CNC router.

▶ Can You Laser Cut Foam Board?

Yes, foam board can be laser cut, but ensure it doesn’t contain PVC. With proper settings, you can achieve clean cuts and detailed designs. Foam boards typically have a foam core sandwiched between paper or plastic. Use low laser power to avoid scorching the paper or deforming the core. Test on a sample piece before cutting the entire project.

▶ How To Maintain A Clean Cut When Cutting Foam?

Maintaining the cleanliness of the laser lens and mirrors is paramount to preserving the quality of the beam. Employ air assist to minimize charred edges and ensure the work area is regularly cleaned to remove debris. Additionally, laser-safe masking tape should be used on the foam surface to protect it from scorch marks during cutting.

Start A Laser Consultant Now!

> What information you need to provide?

> Our contact information

Dive Deeper ▷

You may be interested in

Any Confusion Or Questions For The Foam Laser Cutter, Just Inquire Us At Any Time

Post time: Jan-16-2025