Introduction to Tegris

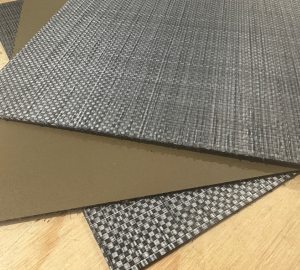

Tegris is a cutting-edge thermoplastic composite material that stands out due to its unique characteristics and performance capabilities.

Composed entirely of polypropylene, tegris is engineered for high durability, making it suitable for various demanding applications.

Its properties make it a preferred choice in industries ranging from military to automotive and consumer products.

Tegris Material

Key Features of Tegris

1. Compressive Strength:

Tegris exhibits compressive strength that is 2 to 15 times greater than conventional thermoplastic composites.

This remarkable strength is maintained even at extremely low temperatures, down to -40°C, providing a significant advantage over standard brittle materials.

2. Toughness:

Tegris can replace traditional glass-reinforced materials while fully meeting required stiffness standards.

This makes it an excellent choice for applications requiring both strength and flexibility.

3. Lightweight:

As Tegris is made of 100% polypropylene, it is significantly lighter than other high-density glass fiber composites.

This lightweight nature is crucial for applications where weight reduction is essential.

4. Recyclability:

Tegris is fully compliant with polypropylene recycling processes, making it an environmentally friendly choice in material selection.

5. Safety:

Unlike glass fiber composites, Tegris poses no safety risks related to skin irritation or tool wear.

It is free from the hazards associated with glass fibers, ensuring safer handling and processing.

How Laser Cutting Tegris Works

1. Laser Generation:

A high-powered laser beam is generated, typically using CO2 or fiber lasers, which produce focused light capable of reaching high temperatures.

2. Focus and Control:

The laser beam is focused through a lens, pinpointing a small area on the Tegris surface.

This targeted energy allows for exact cuts.

3. Material Interaction:

As the laser moves along the material, it heats the Tegris to its melting point, allowing for cutting and shaping without compromising structural integrity.

4. Assist Gas:

An assist gas, such as oxygen or nitrogen, may be used to enhance the cutting process by promoting combustion or cooling the edges, respectively.

5. Control Software:

Advanced software controls the laser cutting machine, allowing for detailed designs to be executed with high precision.

Want to Buy a Laser Cutter?

Advantages of Laser Cutting Tegris

• Precision: Laser cutting provides unparalleled accuracy, enabling complex shapes and designs.

• Minimal Waste: The precision of the process reduces material waste, enhancing cost-effectiveness.

• Flexibility: Laser machines can easily adapt to different designs, making them ideal for custom projects.

• Clean Edges: The process results in clean edges, often eliminating the need for additional finishing.

Applications of Laser Cut Tegris

Tegris is utilized in various sectors due to its superior properties.

Some notable applications include:

• Military Applications:

Tegris is used for blast blankets, flow deflectors, and ballistic panels, where strength and durability are critical.

• Automotive Manufacturing:

Components like chassis protection plates, front wind deflectors, and cargo bed liners leverage Tegris's lightweight and strong characteristics.

• Sports Equipment:

Lightweight structures for kayaks, motorboats, and small boats benefit from Tegris's resilience and weight efficiency.

• Consumer Products:

Tegris is found in helmets, outdoor furniture, and bags, offering durability and safety in everyday items.

Conclusion

Laser cut Tegris offers a unique combination of advanced material properties and precision manufacturing capabilities.

Its compressive strength, toughness, lightweight nature, recyclability, and safety make it an exceptional choice for various demanding applications.

As laser cutting technology continues to evolve, the potential for innovative uses of Tegris will expand, driving advancements across military, automotive, sports, and consumer sectors.

Want To Know More About Laser Cutter?

Recommended Fabric Laser Cutter for Tegris Sheet

The Tegris Material Laser Cutter 160 is a cutting-edge machine designed for precise cutting of Tegris thermoplastic composites.

It utilizes advanced laser technology for accuracy and efficiency, enabling intricate designs with clean edges.

Ideal for various industries, including automotive and military, it features user-friendly controls and robust construction for reliable performance.

The Tegris Material Laser Cutter 160L is a high-precision laser cutting machine designed for Tegris thermoplastic composites.

It offers exceptional accuracy and efficiency for intricate designs, making it ideal for automotive and aerospace applications.

Its robust construction and user-friendly controls ensure reliable performance.

Post time: Jan-14-2025