Introduction

In modern manufacturing, laser cutting has become a widely adopted technique due to its efficiency and precision.

However, the physical properties of different materials demand tailored laser power settings, and process selection requires balancing advantages and limitations.

Material Compatibility and Laser Power

150W (Medium Power)

Optimized for resilient materials such as leather, balancing penetration through dense textures while minimizing burn marks that compromise aesthetics.

600W (Ultra-High Power)

Essential for heat-resistant industrial materials like Fiberglass and ceramic fiber blankets.

Ultra-high power ensures full penetration, avoiding incomplete cuts or delamination caused by insufficient energy.

Want To Know More About Laser Power?

Start a Conversation Now!

Material Comparation

| Fabric Type | Laser Cutting Effects | Traditional Cutting Effects |

| Elastic Fabrics |

Precise cuts with sealed edges, preventing fraying and maintaining shape. |

Risk of stretching and distortion during cutting, leading to uneven edges. |

| Natural Fibers |

Slightly burnt edges on white fabrics, may not be ideal for clean cuts but suitable for seams. |

Clean cuts but prone to fraying, requiring additional treatment to prevent wear. |

| Synthetic Fabrics |

Sealed edges preventing fraying, high precision and speed, reducing production costs. |

Prone to fraying and wear, slower cutting speed, and lower precision. |

| Denim |

Achieves a "stone-washed" effect without chemicals, enhances production efficiency. |

May require chemical processes for similar effects, increased risk of fraying and higher costs. |

| Leather/Synthetics |

Precise cuts and engravings with heat-sealed edges, adds decorative elements. |

Risk of fraying and uneven edges. |

Related Videos

Guide to the Best Laser Power for Cutting Fabrics

This video shows that different laser-cutting fabrics need different laser powers. You'll learn to pick the right power for your material to get clean cuts and avoid burns.

Are you confused about the power for cutting fabric with lasers?We'll give specific power settings for our laser machines to cut fabrics.

Applications of Fabric Laser Cutting

Fashion Industry

Laser cutting creates intricate patterns and complex garment designs with precision, enabling faster production and minimal material waste.

It allows designers to experiment with detailed cuts that are difficult to achieve with traditional methods, and the sealed edges prevent fraying, ensuring a clean finish.

Fabric Sportswear

Fabric Sportswear

Sportswear

Used to process technical fabrics for activewear, offering precise cuts that improve performance.

The technology is leveraged to make accurate cuts in synthetic materials, enhancing garment functionality.

Home Decor

Ideal for cutting and engraving textiles used in curtains, upholstery, and custom interior design elements.

It provides precision and clean edges, reducing waste and improving production speed.

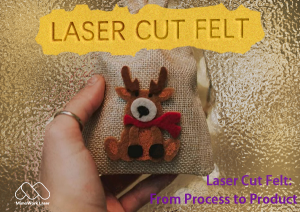

Crafts and Art

Enables the creation of custom designs on fabric for artistic and personalized projects.

It allows for detailed cuts and engravings on various fabrics, offering creative freedom and flexibility.

Craft Fabric

Fabric Car Interiors

Automotive and Medical Industries

Cuts synthetic fabrics for car interiors, seat covers, medical devices, and protective clothing.

The precision and sealed edges ensure durability and a professional finish.

Related Articles

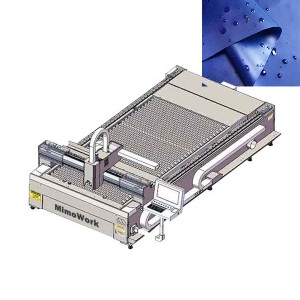

Recommend Machines

Working Area (W * L): 2500mm * 3000mm (98.4’’ *118’’)

Laser Power: 150W/300W/450W

Working Area (W *L): 1600mm * 1200mm (62.9” * 47.2”)

Laser Power: 100W / 130W / 150W

Working Area (W *L): 1800mm * 1300mm (70.87’’ * 51.18’’)

Laser Power: 100W/ 130W/ 300W

Post time: Apr-25-2025