PREFACE TO LASER CUTTING

There are diverse laser applications ranging from laser pen for the tutorial to laser weapons for a long-range strike. Laser Cutting, as a subdivision of applications, has been developed and stands out in cutting and engraving fields. With excellent laser features, outstanding cutting performance, and automatic processing, laser cutting machines are replacing some traditional cutting tools. CO2 Laser is an increasingly popular processing method. The wavelength of 10.6μm is compatible with almost all non-metal materials and laminated metal. From daily fabric and leather, to industrial-used plastic, glass, and insulation, as well as craft materials like wood and acrylic, the laser cutting machine is capable of handling these and realizing excellent cutting effects. So, whether you are working with materials cutting and engraving for commercial and industrial use, or want to invest in a new cutting machine for hobby and gift work, having a little knowledge of laser cutting and laser cutting machine will be a great help for you to make a plan.

TECHNOLOGY

1. What Is The Laser Cutting Machine?

Laser Cutting Machine is a powerful cutting and engraving machine controlled by the CNC system. The agile and powerful laser beam originates from the laser tube where the magical photoelectric reaction happens. The laser tubes for CO2 Laser Cutting are divided into two types: glass laser tubes and metal laser tubes. The laser beam emitted will be transmitted onto the material you are gonna cut by three mirrors and one lens. No mechanical stress, and no contact between the laser head and material. The moment the laser beam carrying enormous heat passes through the material, it is evaporated or sublimated. There is nothing left other than a pretty thin kerf on the material. This is a basic process and principle of CO2 laser cutting. The powerful laser beam matches the CNC system and sophisticated transport structure, and the basic laser cutting machine has been built well to function. To ensure steady running, perfect cutting quality, and safe production, the laser cutting machine is equipped with an air assist system, exhaust fan, exclosure device, and others.

2. How Does Laser Cutter Work?

We know the laser uses the intense heat to cut through the material. Then who send the instruction to direct the moving direction and cutting path? Yes, it is an intelligent cnc laser system including laser cutting software, a control mainboard, circuit system. The automatic control system makes operating more easy and convenient, whether you are a beginner or a professional. We just need to import the cutting file and set the proper laser parameters like speed and power, and the laser cutting machine will start the next cutting process according to our instructions. The whole laser cutting and engraving process is consistent and with repeated precision. No wonder the laser is the champion of speed and quality.

3. Laser Cutter Structure

In general, laser cutting machine consists of four main parts: laser emission area, control system, motion system, and safety system. Every component plays an important role in precise and fast cutting and engraving. Knowing about some structures and components of laser cutting machines, not only helps you to make the right decision when selecting and buying machine, but also provides more flexibility for operation and future production expansion.

Here's an introduction to the main parts of a laser cutting machine:

Laser Source:

CO2 Laser: Utilizes a gas mixture primarily composed of carbon dioxide, making it ideal for cutting non-metal materials like wood, acrylic, fabric, and certain types of stone. It operates at a wavelength of approximately 10.6 micrometers.

Fiber Laser: Uses a solid-state laser technology with optical fibers doped with rare-earth elements like ytterbium. It is highly efficient for cutting metals such as steel, aluminum, and copper, operating at a wavelength of around 1.06 micrometers.

Nd:YAG Laser: Uses a crystal of neodymium-doped yttrium aluminum garnet. It is versatile and can cut both metals and some non-metals, although it is less common than CO2 and fiber lasers for cutting applications.

Laser Tube:

Houses the laser medium (CO2 gas, in the case of CO2 lasers) and produces the laser beam through electrical excitation. The length and power of the laser tube determine the cutting capabilities and the thickness of materials that can be cut. There are two types of laser tube: glass laser tube and metal laser tube. The advantages of glass laser tubes are the budget-friendly and can handle most simple material cutting within a certain precision range. The advantages of metal laser tubes are the long service lifespan and the ability to produce higher laser cutting precision.

Optical System:

Mirrors: Positioned strategically to direct the laser beam from the laser tube to the cutting head. They must be precisely aligned to ensure accurate beam delivery.

Lenses: Focus the laser beam to a fine point, enhancing cutting precision. The focal length of the lens affects the beam’s focus and cutting depth.

Laser Cutting Head:

Focusing Lens: Converges the laser beam to a small spot for precise cutting.

Nozzle: Directs assist gases (like oxygen or nitrogen) onto the cutting area to enhance cutting efficiency, improve cut quality, and prevent debris buildup.

Height Sensor: Maintains a consistent distance between the cutting head and the material, ensuring uniform cut quality.

CNC Controller:

Computer Numerical Control (CNC) System: Manages the machine’s operations, including movement, laser power, and cutting speed. It interprets the design file (usually in DXF or similar formats) and translates it into precise movements and laser actions.

Working Table:

Shuttle Table: The shuttle table, also called pallet changer, is structured with a pass-through design so as to transport in two-way directions. To facilitate the loading and unloading of materials which can minimize or eliminate downtime and meet your specific materials cutting, we designed various sizes to suit every single size of MimoWork laser cutting machines.

Honeycomb Laser Bed: Provides a flat and stable surface with minimal contact area, reducing back reflections and allowing for clean cuts. The laser honeycomb bed allows easy ventilation of heat, dust, and smoke during the laser cutting process.

Knife Strip Table: It is primarily for cutting through thicker materials where you would like to avoid laser bounce back. The vertical bars also allow for the best exhaust flow while you are cutting. Lamellas can be placed individually, consequently, the laser table can be adjusted according to each individual application.

Conveyor Table: The conveyor table is made of stainless steel web which is suitable for thin and flexible materials like film, fabric and leather. With the conveyor system, perpetual laser cutting is becoming feasible. The efficiency of the MimoWork laser systems can be further increased.

Acrylic Cutting Grid Table: Including laser cutting table with grid, the special laser engraver grid prevents back reflection. It is therefore ideal for cutting acrylics, laminates, or plastic films with parts smaller than 100 mm, as these remain in a flat position after the cut.

Pin Working Table: It consists of numerous adjustable pins that can be arranged in various configurations to support the material being cut. This design minimizes contact between the material and the work surface, providing several advantages for laser cutting and engraving applications.

Motion System:

Stepper Motors or Servo Motors: Drive the X, Y, and sometimes Z-axis movements of the cutting head. Servo motors are generally more precise and faster than stepper motors.

Linear Guides and Rails: Ensure smooth and precise motion of the cutting head. They are critical for maintaining cutting accuracy and consistency over long periods.

Cooling System:

Water Chiller: Keeps the laser tube and other components at an optimal temperature to prevent overheating and maintain consistent performance.

Air Assist: Blows a stream of air through the nozzle to clear away debris, reduce heat-affected zones, and improve cutting quality.

Exhaust System:

Remove fumes, smoke, and particulate matter generated during the cutting process, ensuring a clean and safe working environment. Proper ventilation is crucial for maintaining air quality and protecting both the operator and the machine.

Control Panel:

Provides an interface for operators to input settings, monitor machine status, and control the cutting process. It may include a touchscreen display, emergency stop button, and manual control options for fine adjustments.

Safety Features:

Enclosures Device: Protect operators from laser exposure and potential debris. Enclosures are often interlocked to shut down the laser if opened during operation.

Emergency Stop Button: Allows for immediate shutdown of the machine in case of an emergency, ensuring operator safety.

Laser Safety Sensors: Detect any anomalies or unsafe conditions, triggering automatic shutdown or alerts.

Software:

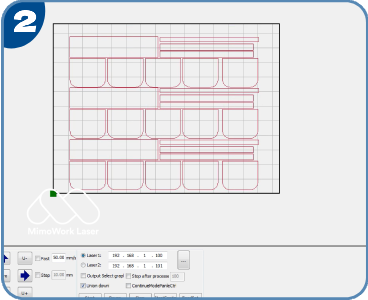

Laser Cutting Software: MimoCUT, the laser cutting software, was designed to simplify your cutting work. Simply uploading your laser cut vector files. MimoCUT will translate the defined lines, points, curves, and shapes into the programming language that can be recognized by the laser cutter software, and guide the laser machine to execute.

Auto-Nest Software: MimoNEST, the laser cutting nesting software helps fabricators to minimize the cost of materials and improves the utilization rate of materials by using advanced algorithms that analyze the variance of parts. In simple terms, it can place the laser cutting files on the material perfectly. Our nesting software for laser cutting can be applied for cutting a wide range of materials as reasonable layouts.

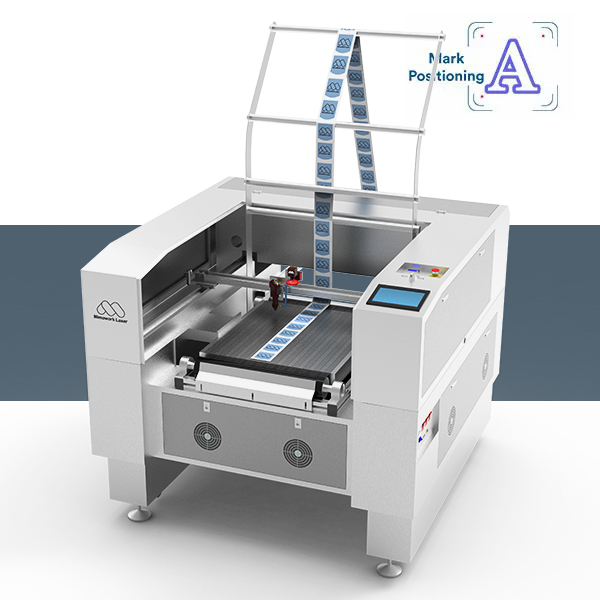

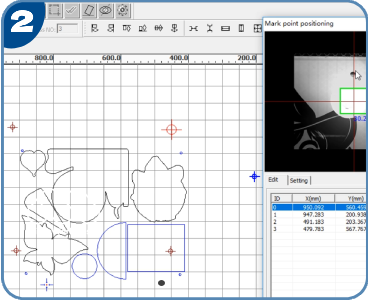

Camera Recognition Software: MimoWork develops CCD camera Laser Positioning System which can recognize and locate the feature areas to help you to save time and increase the laser cutting accuracy at the same time. The CCD camera is equipped beside the laser head to search for the workpiece using registration marks at the start of the cutting procedure. Through this way, printed, woven and embroidered fiducial marks as well as other high-contrast contours can be visually scanned so that laser cutter camera can know where the actual position and dimension of the work pieces are, achieving a precise pattern laser cutting design.

Projection Software: By the Mimo Projection software, the outline and position of materials to be cut will display on the working table, which helps to calibrate the accurate location for higher quality of laser cutting. Usually the Shoes or Footwear of laser cutting adopt the projection device. Such as genuine leather shoes, pu leather shoes, knitting uppers, sneakers.

Prototype Software: By using an HD camera or digital scanner, MimoPROTOTYPE automatically recognizes the outlines and sewing darts of each material piece and generates design files that you can import into your CAD software directly. Comparing with the traditional manual measuring point by point, the efficiency of the prototype software is several times higher. You only need to place the cutting samples on the working table.

Assist Gases:

Oxygen: Enhances cutting speed and quality for metals by facilitating exothermic reactions, which add heat to the cutting process.

Nitrogen: Used for cutting non-metals and some metals to achieve clean cuts without oxidation.

Compressed Air: Used for cutting non-metals to blow away molten material and prevent combustion.

These components work in harmony to ensure precise, efficient, and safe laser cutting operations across a variety of materials, making laser cutting machines versatile tools in modern manufacturing and fabrication.

Multi-functions and flexibility of the camera laser cutter prompt cutting woven label, sticker, and adhesive film to a higher level with high efficiency and top precision. Patterns of printing and embroidery on the patch and woven label need to be accurately cut...

To meet requirements for small business, and custom design, MimoWork designed the compact laser cutter with a desktop size of 600mm * 400mm. The camera laser cutter is suitable for cutting patch, embroidery, sticker, label, and applique used in apparels and accessories...

The contour laser cutter 90, also called CCD laser cutter comes with a machine size of 900mm * 600mm and a fully-enclosed laser design to make sure perfect safety, especially for beginners. With the CCD Camera installed beside the laser head, any pattern and shape...

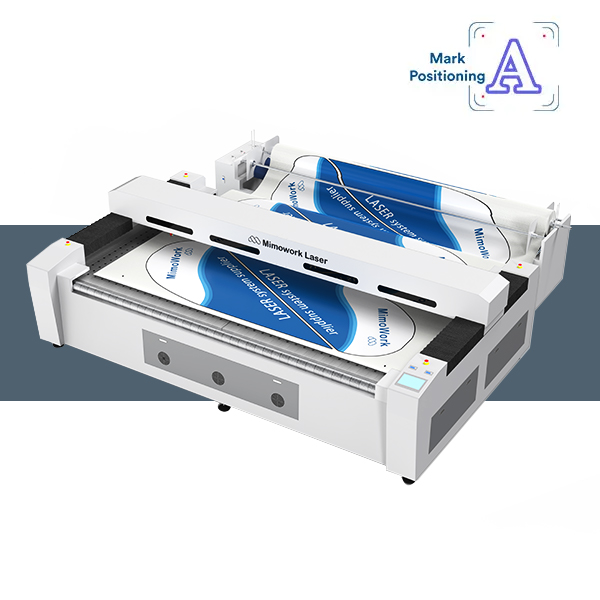

Specifically Engineered for the Signs & Furniture Industry, Harness the Power of Advanced CCD Camera Technology to Perfectly Cut Patterned Printed Acrylic. With Ball Screw Transmission and High-Precision Servo Motor Options, Immerse Yourself in Unmatched Precision and...

Experience the Cutting-Edge Fusion of Art and Technology with Mimowork’s Printed Wood Laser Cutter. Unlock a World of Possibilities as You Seamlessly Cut and Engrave Wood and Printed Wood Creations. Tailored for the Signs & Furniture Industry, Our Laser Cutter Utilizes Advanced CCD...

Featuring a state-of-the-art HD Camera positioned on top, it effortlessly detects contours and transfers pattern data directly to the fabric cutting machine. Say goodbye to complicated cutting methods, as this technology offers the simplest and most precise solution for lace and...

Introducing the Laser Cut Sportswear Machine (160L) – the ultimate solution for dye sublimation cutting. With its innovative HD camera, this machine can accurately detect and transfer pattern data directly to the fabric pattern cutting machine. Our software package offers a range of options..

Introducing the game-changing Sublimation Polyester Laser Cutter (180L) – the ultimate solution for cutting sublimation fabrics with unparalleled precision. With a generous working table size of 1800mm*1300mm, this cutter is specifically designed for processing printed polyester...

Step into a safer, cleaner, and more precise world of sublimation fabric cutting with the Laser Cut Sportswear Machine (Fully-Enclosed). Its enclosed structure offers triple benefits: enhanced operator safety, superior dust control, and better...

To meet cutting requirements for large & wide format roll fabric, MimoWork designed the ultra-wide format sublimation laser cutter with CCD Camera to help contour cut the printed fabrics like banners, teardrop flags, signage, exhibition display, exhibition display, etc. 3200mm * 1400mm of working area...

Contour Laser Cutter 160 is equipped with a CCD camera which is suitable for processing high precision twill letters, numbers, labels, clothing accessories, home textiles. The camera laser cutting machine resorts to the camera software to recognize the feature areas and carry out the accurate pattern cutting...

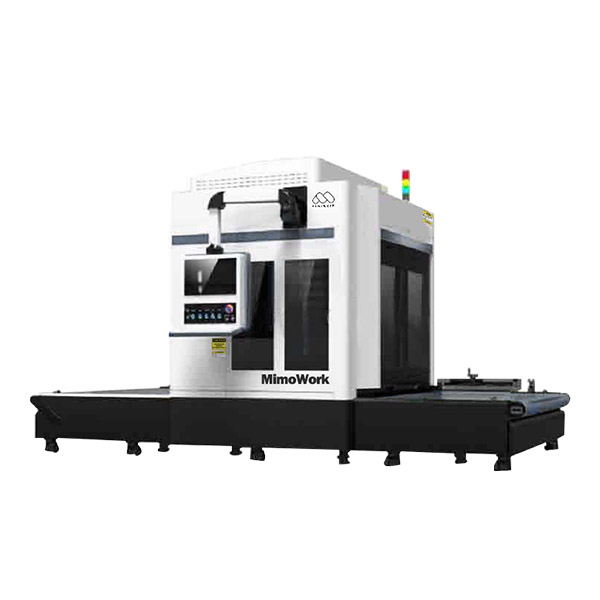

▷ Flatbed Laser Cutting Machine (Customized)

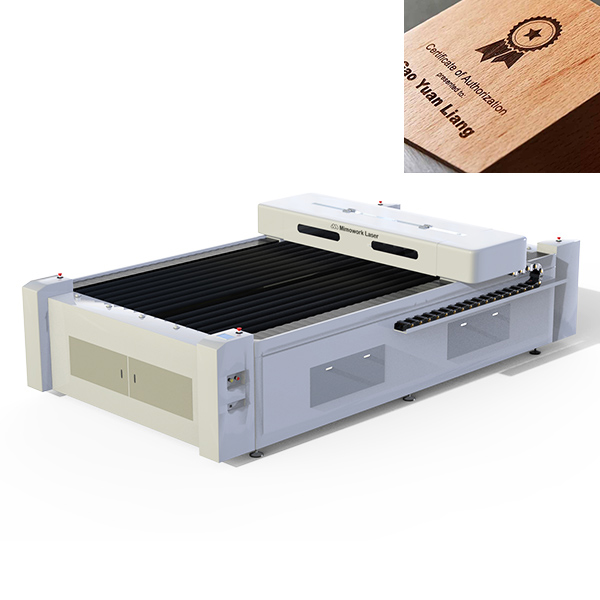

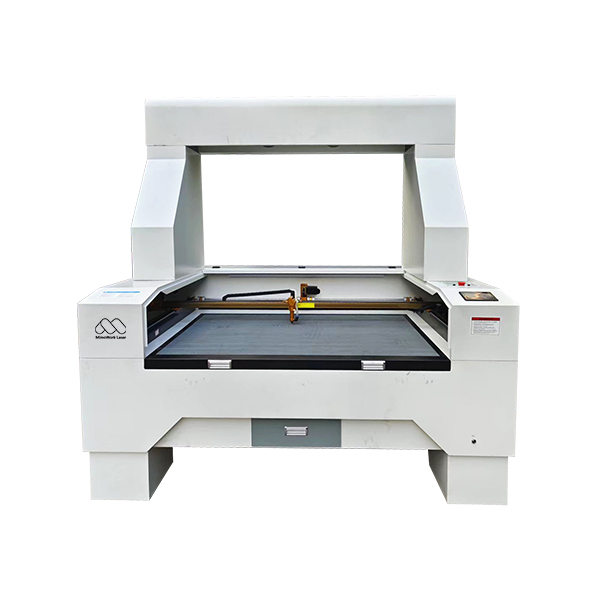

Compact machine size greatly saves space and can accommodate materials that extend beyond the cut width with the two-way penetration design. The Mimowork’s Flatbed Laser Engraver 100 is mainly for engraving and cutting solid materials and flexible materials, like wood, acrylic, paper, textiles...

Wood Laser engraver that can be fully customized to your needs and budget. The MimoWork’s Flatbed Laser Cutter 130 is mainly for engraving and cutting wood (plywood, MDF), it can also be applied to acrylic and other materials. Flexible laser engraving helps to achieve personalized wood...

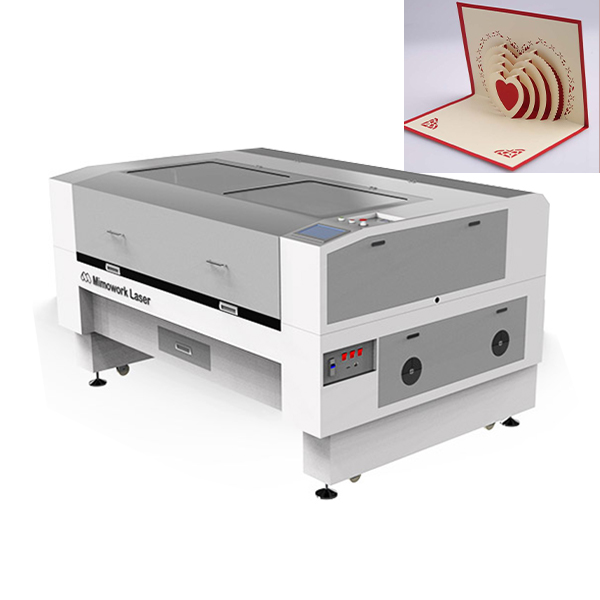

Acrylic Laser engraving machine that can be fully customized to your needs and budget. The Mimowork’s Flatbed Laser Cutter 130 is mainly for engraving and cutting acrylic (plexiglass/PMMA), it can also be applied to wood and other materials. Flexible laser engraving helps to...

Ideal for cutting large size and thick wood sheets to meet diverse advertising and industrial applications. The 1300mm * 2500mm laser cutting table is designed with four-way access. Characterized by high speed, our CO2 wood laser cutting machine can reach a cutting speed of 36,000mm per...

Ideal for laser cutting large size and thick acrylic sheets to meet diverse advertising and industrial applications. The 1300mm * 2500mm laser cutting table is designed with four-way access. Laser cutting acrylic sheets is widely used in the lighting & commercial industry, construction field...

Compact and small laser machine occupies less space and is easy to operate. Flexible laser cutting and engraving fit these customized market demands, which stands out in the field of paper crafts. Intricate paper cutting on invitation cards, greeting cards, brochures, scrapbooking, and business cards...

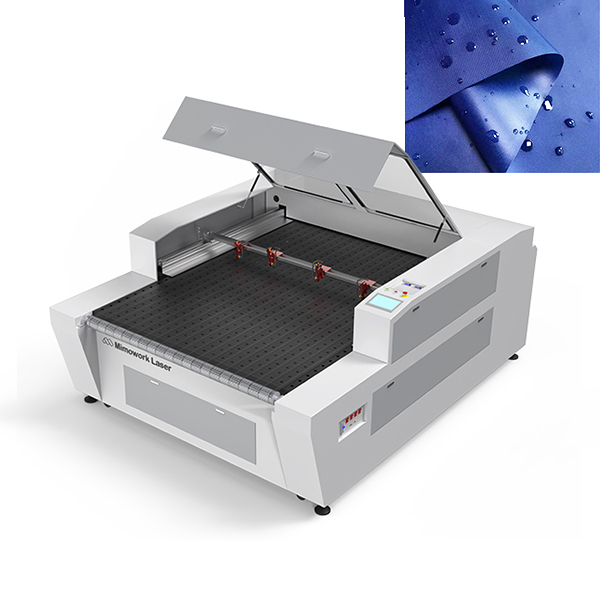

Fitting the regular clothing and garment sizes, the fabric laser cutter machine has a working table of 1600mm * 1000mm. The soft roll fabric is pretty suitable for laser cutting. Except that, leather, film, felt, denim and other pieces can all be laser cut thanks to the optional working table...

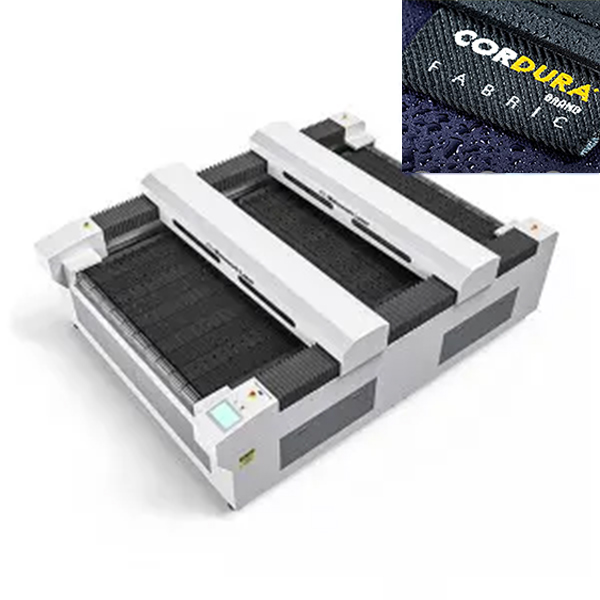

Based on the high strength and density of Cordura, laser cutting is a more efficient processing method especially industrial production of PPE and military gears. The industrial fabric laser cutting machine is featured with a large working area to meet the large format Cordura cutting-like bulletproof...

To meet more varieties of cutting requirements for fabric in different sizes, MimoWork widens the laser cutting machine to 1800mm * 1000mm. Combined with the conveyor table, roll fabric and leather can be allowed to convey and laser cutting for fashion and textiles without interruption. In addition, multi-laser heads...

The Large Format Laser Cutting Machine is designed for ultra-long fabrics and textiles. With a 10-meters long and 1.5-meters wide working table, the large format laser cutter is suitable for most fabric sheets and rolls like tent, parachute, kitesurfing, aviation carpet, advertising pelmet and signage, sailing cloth and etc...

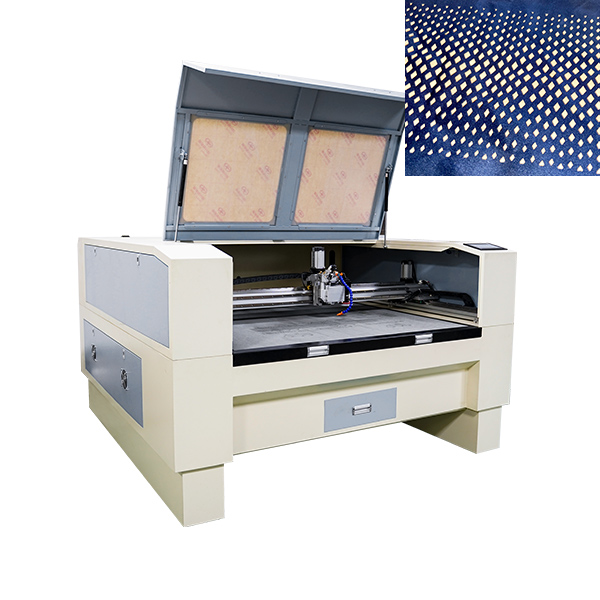

The CO2 laser cutting machine is equipped with a projector system with an accurate positioning function. The preview of the workpiece to be cut or engraved helps you to place the material in the right area, enabling the post-laser cutting and laser engraving to go smoothly and with high accuracy...

Galvo Laser Machine (Cut & Engrave & Perforate)

MimoWork Galvo Laser Marker is a multi-purpose machine. Laser engraving on paper, custom laser cutting paper and paper perforating can all be completed with the galvo laser machine. Galvo laser beam with high precision, flexibility, and lightning speed creates customized...

Flying laser beam from dynamic lens angle of inclination can realize fast processing within the defined scale. You can adjust the height of the laser head to fit the processed material’s size. RF metal laser tube provides high precision marking with fine laser spot to 0.15mm, which is fit for the intricate pattern laser engraving on leather...

The Fly-Galvo laser machine is only equipped with a CO2 laser tube but can provide both fabric laser perforating and laser cutting for garments and industrial fabrics. With a 1600mm * 1000mm working table, the perforated fabric laser machine can carry most fabrics of different formats, realizes consistent laser cutting holes...

GALVO Laser Engraver 80 with a totally enclosed design is definitely your perfect choice for industrial laser engraving and marking. Thanks to its max GALVO view 800mm * 800mm, it is ideal for laser engraving, marking, cutting, and perforating on the leather, paper card, heat transfer vinyl, or any other large pieces...

The large format laser engraver is R&D for large size materials laser engraving & laser marking. With the conveyor system, the galvo laser engraver can engrave and mark on roll fabrics (textiles). You can regard it as a fabric laser engraving machine, carpet laser engraving machine, denim laser engraver...

Budget

Whatever machines you choose to buy, the costs including machine price, shipping cost, installation, and post-maintenance cost are always your first consideration. In the early buying stage, you can determine your production's most important cutting requirements within a certain budget limit. Find the laser configurations and laser machine options matching the functions and budget. Besides, you need to consider the installation and operation costs, such as if there are extra training fees, whether to hire labor, etc. That helps you to select the suitable laser machine supplier and machine types within budget.

The laser cutting machine prices vary according to the machine types, configurations, and options. Tell us your requirements and budget, and our laser specialist will recommend the laser cutting machine for you to choose. ⇨ MimoWork Laser

Laser Souce

When investing in a laser cutting machine, you need to know which laser source is capable of cutting through your materials and reaching the expected cutting effect. There are two common laser source: fiber laser and CO2 laser. Fiber laser performs well in cutting and marking on metal and alloy materials. CO2 laser is specialized in cutting and engraving non-metal materials. Due to the extensive use of CO2 lasers from the industry level to daily home use level, it is capable and easy to operate. Discuss your material with our laser expert, and then determine the suitable laser source.

Machine Configuration

After determining the laser source, you need to discuss your specific requirements for cutting materials like cutting speed, production volume, cutting precision, and material properties with our laser specialist. That determines what laser configurations and options are suitable and can reach the optimal cutting effect. For example, if you have high demands for daily production output, cutting speed and efficiency will be your first consideration. Multiple laser heads, autofeeding and conveyor systems, and even some auto-nesting software may improve your production efficiency. If you are obsessed with cutting precision, maybe a servo motor and metal laser tube are more appropriate for you.

Working Area

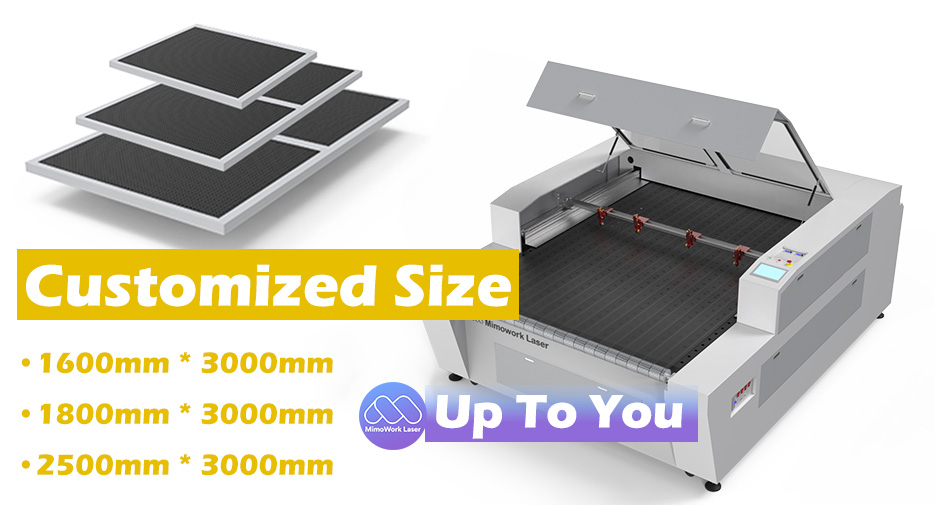

The working area is a significant factor in choosing machines. Usually, laser machine suppliers inquire about your material information, especially material size, thickness, and pattern size. That determines the format of the working table. And laser expert will analyze your pattern size and shape contour by discussing with you, to find an optimal feeding mode to match the working table. We have some standard working size for laser cutting machine, that can meet most clients' requirements, but if you have special material and cutting requirements, please keep us informed, our laser expert is professional and experienced to handle your concern.

Craft

Your own machine

If You Have Special Requirements for Machine Size, Talk to Us!

Machine Manufacturer

All right, you have known your own material information, cutting requirements, and basic machine types, the next step you need to search for a reliable laser cutting machine manufacturer. You can search on Google, and YouTube, or consult your friends or partners, either way, the reliability and authenticity of the machine suppliers are always the most important. Try to email them, or chat with their laser expert on WhatsApp, to learn more about the machine production, where the factory lies in, how to train and guide after getting the machine, and some such. Some clients ever ordered the machine from small factories or third-party platforms due to the low price, however, once the machine has some problems, you never get any help and support, which will delay your production and waste time.

MimoWork Laser Says: We always put the client's requirements and use experience first. What you get is not only a beautiful and sturdy laser machine, but also a set of complete service and support from installation, training to operation.

① Find A Reliable Manufacturer

Google & YouTube Search, or visit the local reference

② Glance at it's Website or YouTube

Check out the machine types and company information

③ Consult the Laser Expert

Send an email or chat via WhatsApp

⑥ Place an Order

Determine the payment term

⑤ Determine the Transportation

shipping or air freight

④ Online Meeting

Discuss the optimal laser machine soultion

About the Consultation & Meeting

> What information you need to provide?

> Our contact information

OPERATION

7. How To Use Laser Cutting Machine?

Laser Cutting Machine is an intelligent and automatic machine, with the support of a CNC system and laser cutting software, the laser machine can deal with complex graphics and plan the optimal cutting path automatically. You just need to import the cutting file to the laser system, select or set the laser cutting parameters like speed and power, and press the start button. The laser cutter will finish the rest of the cutting process. Thanks to the perfect cutting edge with a smooth edge and clean surface, you do not need to trim or polish the finished pieces. The laser cutting process is fast and the operation is easy and friendly to beginners.

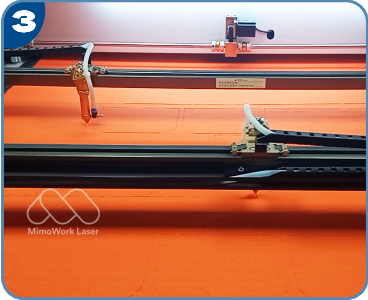

▶ Example 1: Laser Cutting Roll Fabric

Step 1. Put the Roll Fabric on the Auto-Feeder

Prepare the Fabric: Put the roll fabric on the auto feeding system, keep the fabric flat and edge neat, and start the auto feeder, place the roll fabric on the convertor table.

Laser Machine: Choose the fabric laser cutting machine with an auto feeder and conveyor table. The machine working area needs to match the fabric format.

▶

Step 2. Import the Cutting File & Set the Laser Parameters

Design File: Import the cutting file to the laser cutting software.

Set the Parameters: In general, you need to set the laser power and laser speed according to material thickness, density, and the requirements for cutting precision. Thinner materials require lower power, you can test laser speed to find an optimal cutting effect.

▶

Step 3. Start Laser Cutting Fabric

Laser Cut: It's available for multiple laser cutting heads, you can choose two laser heads in one gantry, or two laser heads in two independent gantry. That is different from laser cutting productivity. You need to discuss with our laser expert about your cutting pattern.

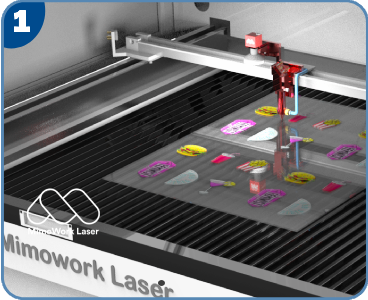

▶ Example 2: Laser Cutting Printed Acrylic

Step 1. Put the Acrylic Sheet on the Working Table

Put the Material: Put the printed acrylic on the working table, for laser cutting acrylic, we used the knife strip cutting table that can prevent the material from being burnt.

Laser Machine: We suggest using the acrylic laser engraver 13090 or large laser cutter 130250 to cut acrylic. Due to the printed pattern, a CCD camera is required to ensure precise cutting.

▶

Step 2. Import the Cutting File & Set the Laser Parameters

Design File: Import the cutting file to the camera recognition software.

Set the Parameters: In general, you need to set the laser power and laser speed according to material thickness, density, and the requirements for cutting precision. Thinner materials require lower power, you can test laser speed to find an optimal cutting effect.

▶

Step 3. CCD Camera Recognize the Printed Pattern

Camera Recognition: For printed material like printed acrylic or sublimation fabric, the camera recognition system is required to recognize and position the pattern, and instruct the laser head to cut along the right contour.

Step 4. Start Laser Cutting along Pattern Contour

Laser Cutting: Based on the camera positioning, the laser cutting head finds the right position and starts cutting along the pattern contour. The whole cutting process is automatic and consistent.

▶ Tips & Tricks When Laser Cutting

✦ Material Selection:

To reach an optimal laser cutting effect, you need to treat the material beforehand. Keeping the material flat and clean is necessary so that the laser cutting focal length is the same to keep cutting effect consistently great. There are so many different kinds of materials that can be laser cut and engraved, and pre-treatment methods are different, if you are new to this, talking with our laser expert is the best choice.

✦ Test First:

Make a laser test using some pieces of samples, by setting different laser powers, laser speeds to find optimal laser parameters, to result in the perfect cutting effect meeting your requirements.

✦ Ventilation:

Laser cutting material may produce fumes and waste gas, so a well-performed ventilation system is required. We usually equip the exhaust fan according to the working area, machine size, and cutting materials.

✦ Production Safety

For some special materials like composite materials or plastic items, we suggest clients equip the fume extractor for the laser cutting machine. That can make the working environment more clean and safe.

✦ Find the Laser Focus:

Ensure the laser beam is properly focused on the material surface. You can use the following test ways to find the right laser focal length, and adjust the distance from the laser head to the material surface within a certain range around the focal length, to reach the optimal cutting and engraving effect. There are setting differences between laser cutting and laser engraving. For details about how to find the right focal length, please check out the video >>

Video Tutorial: How to Find Right Focus?

▶ Take Care of Your Water Chiller

The water chiller needs to be used in a ventilated and cool environment. And the water tank needs to be cleaned regularly and the water should be changed every 3 months. In winter, adding some antifreeze into the water chiller is necessary to prevent freezing. Learn more about how to maintain the water chill in winter, please check out the page: Freezing-proof Measures for Laser Cutter in Winter

▶ Clean the Focus Lens & Mirrors

When laser cutting and engraving some materials, some fumes, debris, and resin will be produced and left on the mirrors and lens. The accumulated waste generates heat to damage the lens and mirrors, and has an impact on laser power output. So cleaning the focus lens and mirrors is necessary. Dip a cotton swab in water or alcohol to wipe the lens surface, remember not to touch the surface with your hands. There is a video guide about that, check this out >>

▶ Keep the Working Table Clean

Keeping the working table clean is important to provide a clean and flat working area for materials and laser cutting head. The resin and residue not only stain the material, but also affect the cutting effect. Before cleaning the working table, you need to turn off the machine. Then use the vacuum cleaner to remove the dust and debris remaining on the working table and left on the waste collecting box. And clean the working table and the rail with a cotton towel damped by the cleaner. Waiting for the working table to dry, and plug in the power.

▶ Clean the Dust Collection Box

Clean the dust collection box daily. Some debris and residue produced from laser cutting materials fall into the dust collection box. You need to clean the box several times during the day if the production volume is large.

• Periodically verify that safety interlocks are working properly. Ensure the emergency stop button, signal light are running well.

• Install the machine under the guidance of the laser technician. Never turn on your laser cutting machine until it has been fully assembled and all covers are in place.

• Don't use a laser cutter and engraver near any possible heat source. Always keep the area around the cutter free of debris, clutter, and flammable materials.

• Don't try to repair laser cutting machine by yourself - get professional help from laser technician.

• Use laser-safety materials. Some materials engraved, marked, or cut with the laser can produce toxic and corrosive fumes. If you are not sure, please consult your laser expert.

• NEVER operate the system unattended. Ensure the laser machine running under human supervision.

• A Fire Extinguisher Should Be Mounted on the Wall Near the Laser Cutter.

• After cutting some heat-conduction materials, you need tweezers or thick gloves to pick up the material.

• For some materials like plastic, laser cutting may produce a lot of fumes and dust that your working environment does not allow. Then a fume extractor is your best choice, which can absorb and purify the waste, ensuring the working environment is clean and safe.

• Laser safety glasses have specifically designed lenses that are tinted to absorb the laser’s light and prevent it from passing through to the wearer’s eyes. The glasses must be matched to the laser type (and wavelength) that you are using. They also tend to be different colors according to the wavelength they absorb: blue or green for diode lasers, gray for CO2 lasers, and light green for fiber lasers.

FAQ

• How much is a laser cutting machine?

Basic CO2 laser cutters range in price from below $2,000 to over $200,000. The price difference is quite large when it comes to the different configurations of CO2 laser cutters. To understand the cost of a laser machine, you need to consider more than the initial price tag. You should also consider the overall cost of owning a laser machine throughout its lifetime, to better evaluate whether it’s worth investing in a piece of laser equipment. Details about laser cutting machine prices to check out the page: How Much Does A Laser Machine Cost?

• How does laser cutting machine work?

The laser beam starts from the laser source, and is directed and focused by the mirrors and focus lens to the laser head, then shot onto the material. The CNC system controls the laser beam generation, the power and pulse of the laser, and the cutting path of the laser head. Combined with the air blower, exhaust fan, motion device and working table, the basic laser cutting process can be finished smoothly.

• Which gas is used in laser cutting machine?

There are two parts that need the gas: the resonator and the laser cutting head. For the resonator, the gas including high-purity (grade 5 or better) CO2, nitrogen, and helium are required to produce the laser beam. But usually, you don't need to replace these gases. For the cutting head, the nitrogen or oxygen assist gas is required to help protect the material to be processed and improve the laser beam to reach the optimal cutting effect.

• What are the Difference: Laser Cutter VS Laser Cutter?

About MimoWork Laser

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20 years of deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in the worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industries.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

Quickly Learn More:

Dive into the Magic World of Laser Cutting Machine,

Discuss with our Laser Expert!

Post time: May-27-2024