Maintaining your laser cutting machine is crucial, whether you’re already using one or thinking about getting your hands on one.

It’s not just about keeping the machine operational; it’s about achieving those clean cuts and sharp engravings you desire, ensuring your machine runs like a dream every single day.

No matter if you’re creating detailed designs or tackling larger projects, proper maintenance of your laser cutter is the secret sauce to getting top-notch results.

In this article, we’ll focus on CO2 laser cutting and engraving machines, sharing some handy maintenance tips and methods.

First things first: a clean machine is an Efficient machine!

Think of your laser cutter’s lens and mirrors as its eyes. If they’re dirty, your cuts won’t be as crisp. Dust, debris, and residue tend to build up on these surfaces, which can really mess with your cutting precision.

To keep everything running smoothly, make it a routine to clean the lens and mirrors regularly. Trust me, your machine will thank you!

How to clean your lens and mirrors? Three steps are the following:

Disassemble: Unscrew the mirrors and take apart the laser heads to gently remove the lens. Place everything on a soft, lint-free cloth.

Prep Your Tools: Grab a Q-tip and dip it in a lens cleaning solution. For regular cleaning, clean water works well, but if you’re dealing with stubborn dust, an alcohol-based solution is your best bet.

Wipe It Down: Carefully use the Q-tip to clean the surfaces of the lens and mirrors. Just a quick tip: keep your fingers away from the lens surfaces—only touch the edges!

And remember, if your mirrors or lens are damaged or worn out, it’s best to replace them with new ones. Your machine deserves the best!

Video Tutorial: How to Clean & Install Laser Lens?

When it comes to your laser cutting table and workspace, keeping them spotless after each job is essential.

Clearing away leftover materials and debris makes sure nothing gets in the way of the laser beam, allowing for clean, precise cuts every time.

Don’t forget about the ventilation system, either! Make sure to clean those filters and ducts to keep the air flowing and fumes at bay.

Smooth Sailing Tip: Regular inspections might feel like a hassle, but they pay off big time. A quick check on your machine can help catch small issues before they turn into major headaches down the road!

2. Cooling System Maintenance

Now, let’s chat about keeping things cool—literally!

The water chiller is essential for keeping your laser tube at the right temperature.

Regularly checking the water level and quality is key.

Always opt for distilled water to avoid pesky mineral deposits, and don’t forget to change the water periodically to prevent algae from creeping in.

As a general rule, it’s a good idea to change the water in the chiller every 3 to 6 months.

However, this timeline can change based on your water quality and how often you use your machine. If the water starts to look dirty or cloudy, go ahead and swap it out sooner!

Winter Worry? Not with These Tips!

When the temperature drops, so does the risk of your water chiller freezing. Adding antifreeze to the chiller can protect it during those cold months. Just make sure you’re using the right kind of antifreeze and follow the manufacturer’s instructions for the correct ratio.

If you want to know about how to add antifreeze into the water chiller to protect your machine from freezing. Check out the guide: 3 Tips to protect your water chiller and laser machine

And don’t forget: consistent water flow is essential. Make sure the pump is working properly and that there are no blockages. An overheated laser tube can lead to costly repairs, so a little attention here goes a long way.

3. Laser Tube Maintenance

Your laser tube is the heart of your laser cutting machine.

Maintaining its alignment and efficiency is essential for ensuring cutting power and precision.

Make it a habit to regularly check the alignment.

If you spot any signs of misalignment—such as inconsistent cuts or reduced beam intensity—be sure to realign the tube following the manufacturer’s guidelines.

Keeping everything in line will keep your cuts sharp!

Pro Tip: Don’t push your machine to its limits!

Running the laser at maximum power for extended periods can shorten the lifespan of your tube. Instead, adjust the power settings according to the material you’re cutting.

Your tube will appreciate it, and you’ll enjoy a longer-lasting machine!

There are two types of CO2 laser tubes: RF laser tubes and glass laser tubes.

RF Laser Tubes:

>> Sealed units that require minimal maintenance.

>> Typically last between 20,000 to 50,000 hours of operation.

>> Top brands include Coherent and Synrad.

Glass Laser Tubes:

>> Commonly used and treated as consumable goods.

>> Generally need replacement every two years.

>> Average service life is around 3,000 hours, but lower-end tubes may only last 1,000 to 2,000 hours.

>> Reliable brands include RECI, Yongli Laser, and SPT Laser.

When selecting a laser cutting machine, consult with their experts to understand the types of laser tubes they offer!

If you are not sure about how to choose laser tubes for your machine, why not talk with our laser expert to have a deep discussion?

Chat With Our Team

MimoWork Laser

(A Professional Laser Machine Manufacturer)

4. Winter Maintenance Tips

Winter can be tough on your machine, but with a few extra steps, you can keep it running smoothly.

If your laser cutter is in an unheated space, consider moving it to a warmer environment. Cold temperatures can affect the performance of electronic components and lead to condensation inside the machine. What is the suitable temperature for laser machine? Take a peek at the page to find more.

A Warm Start: Before cutting, allow your machine to warm up. This prevents condensation from forming on the lens and mirrors, which could interfere with the laser beam.

After the machine warms up, inspect it for any signs of condensation. If you spot any, give it time to evaporate before use. Trust us, avoiding condensation is key to preventing short-circuits and other damage.

5. Lubrication of Moving Parts

Keep things moving smoothly by regularly lubricating the linear rails and bearings. These components are crucial for allowing the laser head to glide effortlessly across the material.

Here’s what to do:

1. Apply a Light Lubricant: Use a light machine oil or lubricant to prevent rust and ensure fluid motion.

2. Wipe Away Excess: After applying, be sure to wipe away any excess lubricant. This helps prevent dust and debris from accumulating.

3. Regular maintenance will keep your machine running efficiently and prolong its lifespan!

Drive Belts, Too! Drive belts play a critical role in ensuring the laser head moves accurately. Regularly inspect them for signs of wear or slackness, and tighten or replace them as needed.

The electrical connections in your machine are like its nervous system.

1. Regular Checks

>> Inspect for Wear: Look for any signs of wear, corrosion, or loose connections.

>> Tighten and Replace: Tighten any loose connections and replace damaged wires to keep everything functioning smoothly.

2. Stay Updated!

Don’t forget to keep your machine’s software and firmware up to date. Regular updates often include:

>> Performance Improvements: Enhancements to efficiency.

>> Bug Fixes: Solutions to existing issues.

>> New Features: Tools that can streamline your workflow.

Staying current ensures better compatibility with new materials and designs, making your machine even more efficient!

Last but certainly not least, regular calibration is key to maintaining cutting accuracy.

1. When to Recalibrate

>> New Materials: Every time you switch to a different material.

>> Decline in Quality: If you notice a decrease in cutting quality, it’s time to adjust your machine’s cutting parameters—like speed, power, and focus.

2. Fine-Tune for Success

>> Adjust the Focus Lens: Regularly fine-tuning the focus lens ensures the laser beam is sharp and accurately focused on the material surface.

>> Determine Focal Length: Find the right focal length and measure the distance from the focus to the material surface. Proper distance is essential for optimal cutting and engraving quality.

If you're unsure about laser focus or how to find the right focal length, be sure to check out the video below!

Video Tutorial: How to Find the Right Focal Length?

For detailed operation steps, please check out the page to find more: CO2 Laser Lens Guide

Conclusion: Your Machine Deserves the Best

By following these maintenance tips, you’re not just prolonging the life of your CO2 laser cutting machine—you’re also ensuring that every project meets the highest standards of quality.

Proper maintenance minimizes downtime, reduces repair costs, and maximizes productivity. And remember, winter calls for special care, like adding antifreeze to your water chiller and warming up your machine before use.

Ready for More?

If you’re looking for top-notch laser cutters and engravers, we’ve got you covered.

Mimowork offers a range of machines designed for various applications:

• Laser Cutter and Engraver for Acrylic & Wood:

Perfect for those intricate engraving designs and precise cuts on both materials.

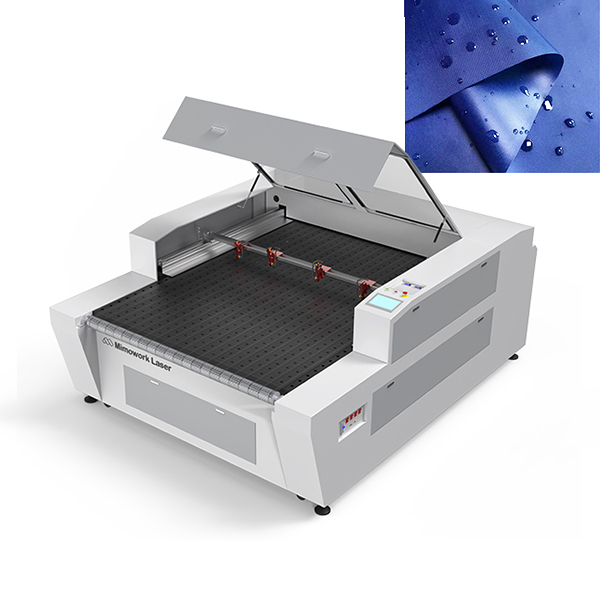

• Laser Cutting Machine for Fabric & Leather:

High automation, ideal for those working with textiles, ensuring smooth, clean cuts every time.

• Galvo Laser Marking Machine for Paper, Denim, Leather:

Fast, efficient, and perfect for high-volume production with custom engraving details and markings.

Learn More about Laser Cutting Machine, Laser Engraving Machine

Glance at the Our Machine Collection

Who We Are?

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan, China. With over 20 years of deep operational expertise, we specialize in producing laser systems and offering comprehensive processing and production solutions to small and medium-sized enterprises (SMEs) across a wide array of industries.

Our extensive experience in laser solutions for both metal and non-metal material processing has made us a trusted partner worldwide, particularly in the fields of advertisement, automotive & aviation, metalware, dye sublimation applications, fabric, and textiles industry.

Unlike many others, we control every part of the production chain, ensuring our products consistently deliver excellent performance. Why settle for anything less when you can rely on a solution crafted by experts who understand your needs?

You may be Interested

More Video Ideas >>

How to Maintain & Install Laser Tube?

How to Select Laser Cutting Table?

How Does Laser Cutter Work?

We are a Professional Laser Cutting Machine Manufacturer,

What Your Concern, We Care!

Post time: Aug-30-2024