Laser cutting acrylic provides a safe, efficient, and precise method for creating a wide variety of products and designs.This guide delves deeply into the principles, advantages, challenges, and practical techniques of laser cutting acrylic, serving as an essential resource for beginners and professionals alike.

Content

1. Introduction to Laser Cutting Of Acrylic

What Is cutting acrylic

with laser?

Cutting acrylic with laser involves using a high-powered laser beam, guided by a CAD file, to cut or engrave specific designs onto acrylic materials.

Unlike traditional methods such as drilling or sawing, this technique relies on precise laser technology to vaporize the material cleanly and efficiently, minimizing waste and delivering superior results.

This method is particularly suitable for industries that demand high precision, intricate detailing, and consistent output, making it the preferred choice over conventional cutting methods.

▶ Why cut acrylic with laser?

Laser technology offers unparalleled benefits for acrylic cutting:

• Smooth Edges: Produces flame-polished edges on extruded acrylic, reducing post-processing needs.

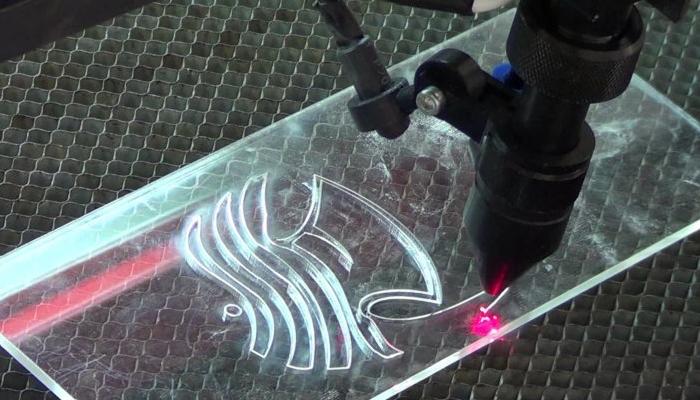

• Engraving Options: Creates frosty white engravings on cast acrylic for decorative and functional applications.

• Precision and Repeatability: Ensures uniform results for complex designs.

• Versatility: Suitable for both small-scale custom projects and mass production.

LED Acrylic Stand White

▶ Applications Of Acrylic Laser Cutting Machine

Laser-cut acrylic has a wide range of applications across multiple sectors:

✔ Advertising: Custom signage, illuminated logos, and promotional displays.

✔ Architecture: Building models, decorative panels, and transparent partitions.

✔ Automotive: Dashboard components, lamp covers, and windshields.

✔ Household Items: Kitchen organizers, coasters, and aquariums.

✔ Awards and Recognition: Trophies and plaques with personalized engravings.

✔ Jewelry: High-precision earrings, pendants, and brooches.

✔ Packaging: Durable and aesthetically pleasing boxes and containers.

>> Check out the videos about cutting acrylic with laser

Any ideas about laser cutting of acrylic?

▶ CO2 VS Fiber Laser: Which One Suits Cutting Acrylic

For cutting acrylic, a CO2 Laser is definitely the best choice due to its inherent optical property.

As you can see in the table, CO2 lasers typically produce a focused beam at a wavelength of around 10.6 micrometers, which is readily absorbed by acrylic. However, fiber lasers operate at a wavelength of around 1 micrometer, which is not fully absorbed by wood compared to CO2 lasers. So if you want to cut or mark on metal, the fiber laser is great. But for these non-metal like wood, acrylic, textile, CO2 laser cutting effect is incomparable.

2. Advantages and Disadvantages of Laser Cutting Of Acrylic

▶ Advantages

✔ Smooth Cutting Edge:

The powerful laser energy can instantly cut through the acrylic sheet in a vertical direction. The heat seals and polishes the edge into being smooth and clean.

✔ Non-Contact Cutting:

Laser cutter features contactless processing, getting rid of the worry about material scratches and cracking because there is no mechanical stress. No need to replace tools and bits.

✔ High Precision:

Super high precision makes acrylic laser cutter cut into intricate patterns according to the designed file. Suitable for exquisite custom acrylic decor and industrial & medical supplies.

✔ Speed and Efficiency:

Strong laser energy, no mechanical stress, and digital auto-control, greatly increase the cutting speed and the whole production efficiency.

✔ Versatility:

CO2 laser cutting is versatile to cut acrylic sheets of various thicknesses. It is suitable for both thin and thick acrylic materials, providing flexibility in project applications.

✔ Minimal Material Waste:

The focused beam of a CO2 laser minimizes material waste by creating narrow kerf widths. If you are working with mass production, the intelligent laser nesting software can optimize the cutting path, and maximize the material use rate.

Crystal Clear Edge

Intricate Cut Pattern

▶ Disadvantages

Engraved Photos On Acrylic

While the advantages of cutting acrylic with laser are abundant, it’s equally important to consider the drawbacks:

Variable Production Rates:

The production rate when cutting acrylic with laser can sometimes be inconsistent. Factors such as the type of acrylic material, its thickness, and the specific laser cutting parameters play a role in determining the speed and uniformity of production. These variables can affect the overall efficiency of the process, especially in large-scale operations.

3. Process of cutting acrylic with laser cutter

Laser cutting acrylic is a precise and efficient method for creating detailed designs, but achieving optimal results requires understanding the materials and the process. Depending on the CNC system and precise machine components, the acrylic laser cutting machine is automatic and easy to operate.

You just need to upload the design file to the computer, and set the parameters according to material features and cutting requirements.

Here’s a step-by-step guide that includes important considerations for working with acrylics.

Step 1. Prepare Machine And Acrylic

Acrylic Preparation: keep the acrylic flat and clean on the working table, and better to test using scrap before real laser cutting.

Laser Machine: determine the acrylic size, cutting pattern size, and acrylic thickness, to choose suitable machine.

Step 2. Set Software

Design File: import the cutting file to the software.

Laser Setting: Talk to our laser expert to get general cutting parameters. But various materials have different thicknesses, purity, and density, so testing before is the best choice.

Step 3. Laser Cut Acrylic

Start Laser Cutting: The laser will automatically cut the pattern according to the given path. Remember to open the ventilation to clear away the fume, and turn down the air blowing to ensure the edge is smooth.

By carefully following these steps, you can achieve precise, high-quality results when laser cutting acrylic.

Proper preparation, setup, and safety measures are crucial for success, enabling you to fully leverage the advantages of this advanced cutting technology.

Video Tutorial: Laser Cutting & Engraving Acrylic

4. Factors Influencing Cutting Acrylic With Laser

Laser cutting acrylic requires precision and an understanding of several factors that affect the quality and efficiency of the process.Below, we explore key aspects to consider when cutting acrylic.

▶ Laser Cutting Machine Settings

Properly configuring the settings of your laser cutting machine is vital to achieving optimal results.Machines come with various adjustable features that affect the cutting process, including:

1. Power

• A general rule is to allocate 10 watts (W) of laser power for every 1 mm of acrylic thickness.

• Higher peak power enables rapid cutting of thin materials and provides better cut quality for thicker materials.

2. Frequency

Influences the number of laser pulses per second, impacting the cut's precision.The optimal laser frequency depends on the type of acrylic and the desired cut quality:

• Cast Acrylic: Use high frequencies (20–25 kHz) for flame-polished edges.

• Extruded Acrylic: Lower frequencies (2–5 kHz) work best for clean cuts.

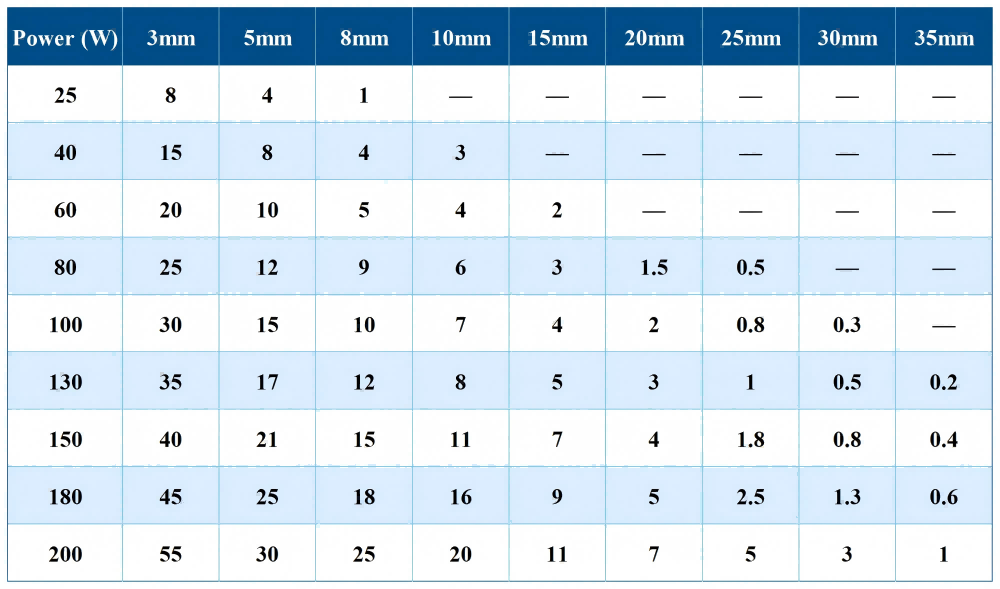

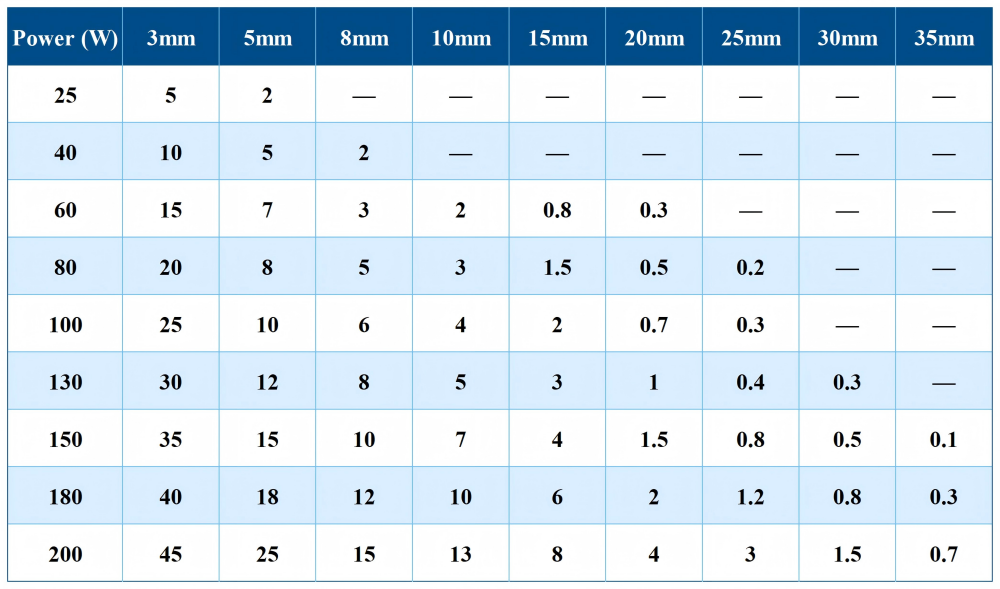

3.Speed

The appropriate speed varies based on laser power and material thickness.Faster speeds reduce cutting time but may compromise precision for thicker materials.

Tables detailing maximum and optimal speed for different power levels and thicknesses can serve as useful references.

Table 1: CO₂ Laser Cutting Settings Chart for Maximum Speed

Table Credit: https://artizono.com/

Table 2: CO₂ Laser Cutting Settings Chart for Optimal Speed

Table Credit: https://artizono.com/

▶ Acrylic Thickness

The thickness of the acrylic sheet directly impacts the required laser power. Thicker sheets demand more energy to achieve a clean cut.

• As a general guideline, approximately 10 watts (W) of laser power is needed for every 1 mm of acrylic thickness.

• For thinner materials, you can use lower power settings and slower speeds to ensure sufficient energy input for cutting.

• If the power is too low and cannot be compensated by reducing speed, the quality of the cut may fall short of application requirements.

Optimizing power settings according to the material's thickness is crucial for achieving smooth, high-quality cuts.

By considering these factors—machine settings, speed, power, and material thickness—you can enhance the efficiency and precision of acrylic laser cutting. Each element plays a pivotal role in ensuring the success of your project.

5. Recommended Acrylic Laser Cutting Machine

MimoWork Laser Series

▶ Popular Acrylic Laser Cutter Types

Printed Acrylic Laser Cutter: Vibrant Creativity, Ignited

To meet the requirements for cutting UV-printed acrylic, patterned acrylic, MimoWork designed the professional printed acrylic laser cutter. Equipped with the CCD camera, the camera laser cutter can accurately recognize the pattern position and direct the laser head to cut along the printed contour. CCD camera laser cutter is a great help for laser cut printed acrylic, especially with the support of the honey-comb laser cutting table, the pass-through machine design. From Customizable Working Platforms to Exquisite Craftsmanship, Our Cutting-Edge Laser Cutter Transcends Boundaries. Specifically Engineered for the Signs, decorations, crafts and gifts Industry, Harness the Power of Advanced CCD Camera Technology to Perfectly Cut Patterned Printed Acrylic. With Ball Screw Transmission and High-Precision Servo Motor Options, Immerse Yourself in Unmatched Precision and Flawless Execution. Let Your Imagination Soar to New Heights as You Redefine Artistic Excellence with Unparalleled Ingenuity.

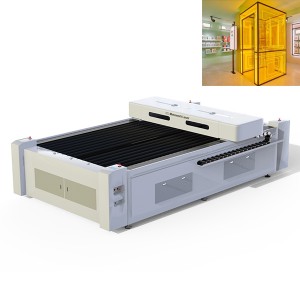

Acrylic Sheet Laser Cutter, your best industrial CNC laser cutting machine

Ideal for laser cutting large size and thick acrylic sheets to meet diverse advertising and industrial applications. The 1300mm * 2500mm laser cutting table is designed with four-way access. Featured at high speed, our acrylic sheet laser cutting machine can reach a cutting speed of 36,000mm per minute. And the ball screw and servo motor transmission system ensure the stability and precision for the high-speed moving of the gantry, which contributes to laser cutting large format materials while ensuring efficiency and quality. laser cutting acrylic sheets is widely used in the lighting & commercial industry, construction field, chemical industry, and other fields, daily we are most common in advertising decoration, sand table models, and display boxes, such as signs, billboards, light box panel, and English letter panel.

(Plexiglass/PMMA) Acrylic Laser Cutter, your best industrial CNC laser cutting machine

Ideal for laser cutting large size and thick acrylic sheets to meet diverse advertising and industrial applications. The 1300mm * 2500mm laser cutting table is designed with four-way access. Featured at high speed, our acrylic laser cutter machine can reach a cutting speed of 36,000mm per minute. And the ball screw and servo motor transmission system ensure the stability and precision for the high-speed moving of the gantry, which contributes to laser cutting large format materials while ensuring efficiency and quality. Not only that, thick acrylic can be cut by the higher power laser tube of optional 300W and 500W. The CO2 laser cutting machine can cut super thick and large solid materials, like acrylic and wood.

Get More Advice about Acrylic Laser Cutting Machine Purchase

6. General Tips for cutting acrylic with laser

When working with acrylic, it’s crucial to follow these guidelines to ensure safety and achieve the best results:

1. Never Leave the Machine Unattended

• Acrylic is highly flammable when exposed to laser cutting, making constant supervision essential.

• As a general safety practice, never operate a laser cutter—regardless of the material—without being present.

2. Choose the Right Type of Acrylic

• Select the appropriate acrylic type for your specific application:

o Cast Acrylic: Ideal for engraving due to its frosted white finish.

o Extruded Acrylic: Better suited for cutting, producing smooth, flame-polished edges.

3. Elevate the Acrylic

• Use supports or spacers to lift the acrylic off the cutting table.

• Elevation helps eliminate backside reflections, which can cause unwanted marks or damage to the material.

Laser Cutting Acrylic Sheet

7. Laser Cutting of Acrylic FAQs

▶ How Does Laser Cutting Acrylic Work?

Laser cutting involves focusing a powerful laser beam onto the surface of the acrylic, which vaporizes the material along the designated cutting path.

This process shapes the acrylic sheet into the desired form. Additionally, the same laser can be used for engraving by adjusting the settings to vaporize only a thin layer from the acrylic's surface, creating detailed surface designs.

▶ What Type of Laser Cutter Can Cut Acrylic?

CO2 laser cutters are the most effective for cutting acrylic.

These emit laser beams in the infrared region, which acrylic can absorb, regardless of color.

High-power CO2 lasers can cut through acrylic in a single pass, depending on the thickness.

▶ Why Choose a Laser Cutter for Acrylic

Instead of Conventional Methods?

Laser cutting offers precise, smooth, and constant cutting edges with no contact with the material, reducing breakage.

It is highly flexible, minimizes material waste, and does not cause tool wear.

Additionally, laser cutting can include labeling and fine detailing, offering superior quality compared to conventional methods.

▶ Can I Laser Cut Acrylic Myself?

Yes, you can laser cut acrylic as long as you have the right materials, tools, and expertise.

However, for professional-quality results, it’s often recommended to hire qualified professionals or specialized companies.

These businesses have the necessary equipment and skilled staff to ensure high-standard results.

▶ What Is the Largest Size of Acrylic That

Can Be Laser Cut?

The size of acrylic that can be cut depends on the laser cutter’s bed size.

Some machines have smaller bed sizes, while others can accommodate larger pieces, up to 1200mm x 2400mm or even more.

▶ Does Acrylic Burn During Laser Cutting?

Whether acrylic burns during cutting depends on the laser’s power and speed settings.

Typically, slight burning occurs on the edges, but by optimizing the power settings, you can minimize these burns and ensure cleaner cuts.

▶ Is All Acrylic Suitable for Laser Cutting?

Most acrylic types are suitable for laser cutting, but variations in color and material type can influence the process.

It’s important to test the acrylic you intend to use to ensure it is compatible with your laser cutter and produces the desired results.

Start A Laser Consultant Now!

> What information you need to provide?

|

✔ |

Specific Material (such as plywood, MDF) |

|

✔ |

Material Size and Thickness |

|

✔ |

What You Want to Laser To Do? (cut, perforate, or engrave) |

|

✔ |

Maximum Format to be processed |

> Our contact information

You can find us via Facebook, YouTube, and Linkedin.

Dive Deeper ▷

You may be interested in

# how much does a acrylic laser cutter cost?

# how to choose working table for laser cutting acrylic?

# how to find the right focal length for laser cutting acrylic?

# what else material can laser cut?

Any Confusion Or Questions For The Acrylic Laser Cutter, Just Inquire Us At Any Time

Post time: Jan-10-2025