Have you ever come across those stunning laser-cut felt coasters or hanging decorations?

They’re truly a sight to behold—delicate and eye-catching! Laser cutting and engraving felt have become incredibly popular for various applications, like table runners, rugs, and even gaskets.

With their impressive precision and speedy performance, laser felt cutters are perfect for anyone looking to achieve high-quality results without the wait. Whether you’re a DIY enthusiast or a manufacturer of felt products, investing in a laser cutting machine can be a smart and budget-friendly move.

It’s all about combining creativity with efficiency!

Can You Laser Cut Felt?

Absolutely!

Felt can definitely be laser cut, and it’s a fantastic option. Laser cutting is a precise and versatile technique that works beautifully with different materials, including felt.

When diving into this process, just remember to consider the thickness and type of felt you’re using. Tweaking your laser cutter settings—like power and speed—is key to getting the best results. And don’t forget, testing a small sample first is a great way to find that perfect setup for your specific material. Happy cutting!

▶ Laser Cut Felt! You Should Choose CO2 Laser

When it comes to cutting and engraving felt, CO2 lasers really take the lead over diode or fiber lasers. They’re incredibly versatile and work well with a range of felt types, from natural to synthetic.

This makes CO2 laser cutting machines perfect for all sorts of applications, including furniture, interiors, sealing, and insulation.

Curious why CO2 lasers are the go-to choice for felt? Let’s break it down:

Wavelength

CO2 lasers operate at a wavelength (10.6 micrometers) that is well-absorbed by organic materials like fabric. Diode lasers and fiber lasers typically have shorter wavelengths, making them less efficient for cutting or engraving in this context.

Versatility

CO2 lasers are known for their versatility and ability to handle a wide range of materials. Felt, being a fabric, responds well to the characteristics of CO2 lasers.

Precision

CO2 lasers provide a good balance of power and precision, making them suitable for both cutting and engraving applications. They can achieve intricate designs and precise cuts on felt.

▶ What Benefits you Can Get from Laser Cutting Felt?

Intricate Cut Pattern

Crisp & Clean Cutting

Custom Engraved Design

✔ Sealed and Smooth Edge

The heat from the laser can seal the edges of cut felt, preventing fraying and enhancing the overall durability of the material, reducing the need for additional finishing or post-processing.

✔ High Precision

Laser cutting felt provide high precision and accuracy, allowing for intricate designs and detailed engraving on felt materials. Fine laser spot can produce delicate patterns.

✔ Customization

Laser cutting felt and engraving felt enable easy customization. It's ideal for creating unique patterns, shapes, or personalized designs on felt products.

✔ Automation and Efficiency

Laser cutting is a fast and efficient process, making it suitable for both small-scale and mass production of felt items. The digital control laser system can be integrated into the whole production workflow to enhance efficiency.

✔ Reduced Waste

Laser cutting minimizes material waste as the laser beam is focused on the specific areas needed for cutting, optimizing material usage. Fine laser spot and non-contact cutting eliminate the felt damage and waste.

✔ Versatility

Laser systems are versatile and can handle a wide range of felt materials, including wool felt and synthetic blends. Laser cutting, laser engraving and laser perforating can be finished in one pass, to create vivid and various design on felt.

▶ Dive into: Laser Cutting Felt Gasket

LASER - Mass Production & High Precision

▶ What felt is Suitable for Laser Cutting and Engraving?

Natural Felt

Wool felt is a standout when it comes to natural felts. Not only is it flame-retardant, soft to the touch, and skin-friendly, but it also laser cuts beautifully. CO2 lasers are particularly good at handling wool felt, delivering clean edges and allowing for detailed engravings.

If you’re looking for a material that combines quality and versatility, wool felt is definitely the way to go!

Synthetic Felt

Synthetic felt, like polyester and acrylic varieties, is also a great choice for CO2 laser processing. This type of felt provides consistent results and comes with some added benefits, such as improved moisture resistance.

If you’re after durability alongside precision, synthetic felt is definitely worth considering!

Blended Felt

Blended felts, which combine natural and synthetic fibers, are another excellent option for CO2 laser processing. These materials leverage the benefits of both worlds, allowing for effective cutting and engraving while maintaining versatility and durability.

Whether you’re crafting or manufacturing, blended felt can deliver fantastic results!

CO2 lasers are generally suitable for cutting and engraving a variety of felt materials. However, the specific type of felt and its composition can influence the cutting results. For example, laser cutting wool felt may produce unpleasant smell, in this case, you need to turn up the exhaust fan or equip a fume extractor to purify the air.

Different from wool felt, there is no unpleasant smell and charred edge produced during laser cutting synthetic felt, but it is generally not as dense as wool felt so it will have a different feel. Choose the suitable felt material according to your production requirements and laser machine configurations.

* We advice: Make a Laser Test for your Felt Material before Investing in a Felt Laser Cutter and Start Production.

▶ Samples of Laser Cutting & Engraving Felt

• Coaster

• Placement

• Table Runner

• Gasket(Washer)

• Wall Cover

• Bag & Apparel

• Decoration

• Room Divider

• Invitation Cover

• Keychain

Have No Ideas of Laser Felt?

Check Out This Video

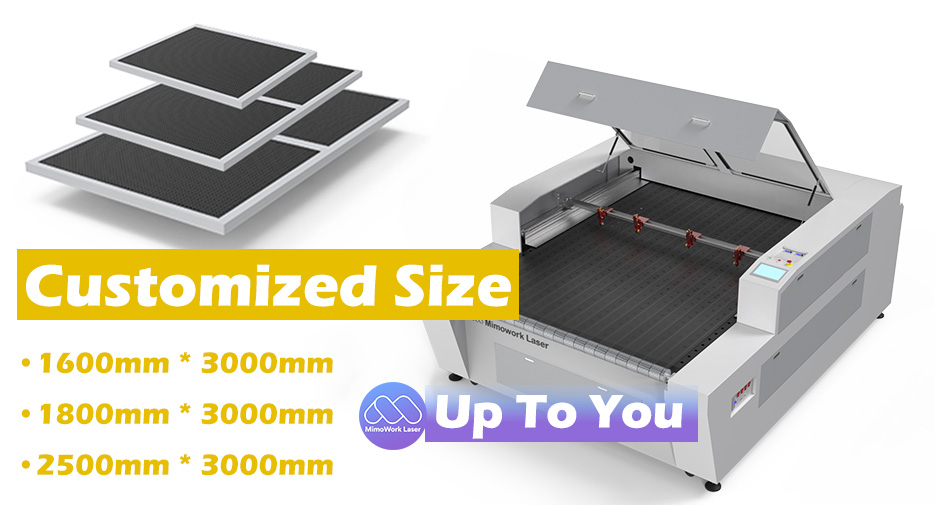

Recommended Felt Laser Cutting Machine

From MimoWork Laser Series

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

Flatbed Laser Cutter 130 is a popular and standard machine for cutting and engraving non-metal materials like felt, foam, and acrylic. Suitable for felt pieces, the laser machine has a 1300mm * 900mm working area that can meet most cutting requirements for felt products. You can use the laser felt cutter 130 to cut and engrave on the coaster and table runner, creating customized designs for your daily use or business.

Working Table Size: 1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 160

The Mimowork’s Flatbed Laser Cutter 160 is mainly for cutting roll materials. This model is especially R&D for soft materials cutting, like textile and leather laser cutting. For roll felt, the laser cutter can feed and cut the material automatically. Not only that, the laser cutter can be equipped with two, three, or four laser heads to reach ultra-high production efficiency and output.

* Besides laser cutting felt, you can use the co2 laser cutter to engrave felt to create customized and intricate engraving design.

Laser cutting felt and laser engraving felt are easy to master and operate. Due to the digital control system, the laser machine can read the design file and instruct the laser head to reach the cutting area and start laser cutting or engraving. All you do is import the file and set done laser parameters, the next step will be left to the laser to finish. Specific operation steps are below:

Step 1. Prepare Machine and Felt

Felt Preparation: For the felt sheet, put it on the working table. For the felt roll, just put it on the auto-feeder. Make sure the felt is flat and clean.

Laser Machine: According to your felt features, size, and thickness to choose suitable laser machine types and configurations. Details to inquire us >

▶

Step 2. Set Software

Design File: Import the cutting file or engraving file to the software.

Laser Setting: There are some common parameters you need to set like laser power, and laser speed.

▶

Step 3. Laser Cut & Engrave Felt

Start Laser Cutting: The laser head will cut and engrave on the felt according to your uploaded file automatically.

▶ Some Tips while Laser Cutting Felt

✦ Material Selection:

Choose the right type of felt for your project. Wool felt and synthetic blends are commonly used in laser cutting.

✦ Test First:

Make a laser test using some felt scraps to find the optimal laser parameters before real production.

✦ Ventilation:

Well-performed ventilation can timely clear away the fumes and odor, especially when laser cutting wool felt.

✦ Fix the material:

We suggest fixing the felt on the working table using some blocks or magnets.

✦ Focus and Alignment:

Ensure the laser beam is properly focused on the felt surface. Proper alignment is crucial for achieving accurate and clean cuts. We have a video tutorial about how to find the right focus. Check to figure out >>

Video Tutorial: How to Find Right Focus?

• Artist and Hobbyist

Customization stands out as one of the most impressive features of laser cutting and engraving felt, particularly for artists and hobbyists. With the ability to design patterns that reflect personal artistic expression, laser technology brings those visions to life with precision.

For individuals engaged in art and craft projects, lasers offer exact cutting and intricate engraving, enabling the creation of unique and detailed designs.

DIY enthusiasts can leverage laser cutting to enhance their felt projects, crafting decorations and gadgets with a level of customization and accuracy that traditional methods may not achieve.

Whether you’re creating art or unique gifts, laser cutting opens up a world of possibilities!

• Fashion Business

high precision cutting and auto-nesting for cutting patterns can greatly increase production efficiency while saving materials to a great extent.

Besides, flexible production gets a faster market response to fashion and trends in apparel and accessories. Fashion designers and manufacturers can use lasers to cut and engrave felt for creating custom fabric patterns, embellishments, or unique textures in clothing and accessories.

There are dual laser heads, four laser heads for felt laser cutting machine, you can choose suitable machine configurations according to your specific requirements.

Mass production and customization production can be met with the help of laser machines.

• Industrial Production

In the realm of industrial production, high precision and efficiency make laser cutting an invaluable asset for manufacturers.

CO2 lasers provide exceptional accuracy when cutting gaskets, seals, and other components used in automotive, aviation, and machine tools.

This technology allows for mass production while maintaining high quality, significantly reducing both time and labor costs.

With the ability to produce intricate designs rapidly and consistently, lasers are a game changer for industries that demand reliability and precision in their manufacturing processes.

• Educational Use

Educational institutions, including schools, colleges, and universities, can greatly benefit from incorporating laser cutting technology into their design and engineering programs. This hands-on approach not only teaches students about materials processing but also fosters innovation in design.

Using lasers to create quick prototypes allows students to bring their ideas to life, encouraging creativity and exploration of material potentials. Educators can guide students in understanding the capabilities of laser cutting, helping them to think outside the box and develop their skills in a practical, engaging manner.

This technology opens new avenues for learning and experimentation in design-focused curricula.

> What information you Need to Provide?

> Our Contact Information

▶ What Kind of Felt can you Laser Cut?

CO2 lasers are well-suited for cutting various types of felt, including:

1. Wool Felt

2. Synthetic Felt (such as polyester and acrylic)

3. Blended Felt (combinations of natural and synthetic fibers)

When working with felt, it's crucial to conduct test cuts to find the optimal settings for each material. Additionally, ensure proper ventilation during the cutting process, as there may be odors and smoke produced. This preparation will help achieve the best results while maintaining a safe working environment.

▶ Is It Safe to Laser Cut Felt?

Yes, laser cutting felt can be safe if proper safety precautions are observed.

Here are some key measures to ensure safety:

1. Ventilation: Ensure good airflow to mitigate odors and smoke.

2. Protective Gear: Wear appropriate safety gear, such as goggles and masks, to protect against fumes.

3. Flammability: Be cautious of the flammability of felt materials and keep flammable materials away from the cutting area.

4. Machine Maintenance: Regularly maintain the laser cutting machine to ensure it operates safely and efficiently.

5. Manufacturer Guidelines: Always follow the manufacturer’s guidelines for safe operation.

By adhering to these practices, you can create a safer environment for laser cutting felt.

▶ Can you Laser Engrave on Felt?

Yes, laser engraving on felt is a common and effective process.

CO2 lasers are particularly well-suited for this task, allowing for the engraving of intricate designs, patterns, or text onto felt surfaces.

The laser beam heats and vaporizes the material, resulting in precise and detailed engravings. This capability makes laser engraving a popular choice for creating personalized items, decorative pieces, and custom designs on felt.

▶ How Thick of Felt can Laser Cut?

The thickness of felt that can be laser cut depends on the configurations and performance of the laser machine. Generally, higher-powered lasers are capable of cutting thicker materials.

For felt, CO2 lasers can typically cut sheets ranging from a fraction of a millimeter up to several millimeters thick.

It's essential to refer to the specific capabilities of your laser machine and conduct test cuts to determine the optimal settings for different felt thicknesses.

▶ Laser Felt Ideas Sharing:

About MimoWork Laser

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20 years of deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in the worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industries.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

Quickly Learn More:

Learn More about Laser Cutting Felt,

Click here to talk with us!

Post time: Feb-26-2024