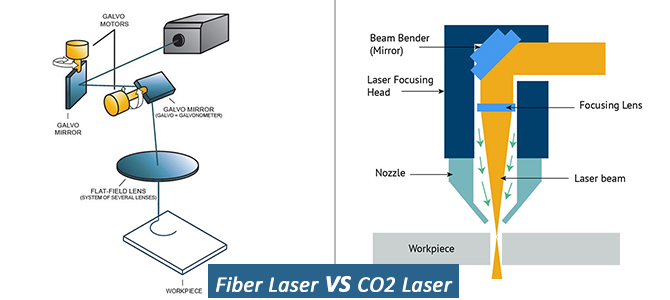

The fiber laser cutting machine is one of the most commonly used laser cutting machines. Unlike the gas laser tube and light transmission of CO2 laser machine, fiber laser cutting machine uses fiber laser and cable to transmit laser beam. The wavelength of the fiber laser beam is only 1/10 of the wavelength produced by the CO2 laser which determines the different use of the two. The main difference between a CO2 laser cutting machine and a fiber laser cutting machine lies in the following aspects.

1. Laser Generator

CO2 laser marking machine uses CO2 laser, and fiber laser marking machine uses fiber laser. The carbon dioxide laser wavelength is 10.64μm, and the optical fiber laser wavelength is 1064nm. The optical fiber laser relies on the optical fiber to conduct the laser, while the CO2 laser needs to conduct the laser by the external optical path system. Therefore, the optical path of the CO2 laser needs to be adjusted before each device is used, while the optical fiber laser does not need to be adjusted.

A CO2 laser engraver uses a CO2 laser tube to produce a laser beam. The main working medium is CO2, and O2, He, and Xe are auxiliary gases. The CO2 laser beam is reflected by the reflecting and focusing lens and focused onto the laser cutting head. Fiber laser machines generate laser beams through multiple diode pumps. The laser beam is then transmitted to the laser cutting head, laser marking head and laser welding head through a flexible fiber optic cable.

2. Materials & Application

The beam wavelength of a CO2 laser is 10.64um, which is easier to be absorbed by non-metallic materials. However, the wavelength of the fiber laser beam is 1.064um, which is 10 times shorter. Because of this smaller focal length, the fiber laser cutter is almost 100 times stronger than a CO2 laser cutter with the same power output. So fiber laser cutting machine, as known as a metal laser cutting machine, is very suitable for cutting metal materials, such as stainless steel, carbon steel, galvanized steel, copper, aluminum, and so on.

CO2 laser engraving machine can cut and carve metal materials, but not so efficiently. It also involves the absorption rate of the material to different wavelengths of the laser. The characteristics of the material determine which type of laser source is the best tool to process. The CO2 laser machine is mainly used for cutting and engraving non-metallic materials. For example, wood, acrylic, paper, leather, fabric, and so on.

Seek a suitable laser machine for your application

3. Other Comparisons between CO2 laser and fiber laser

The lifespan of a fiber laser can reach 100,000 hours, the lifespan of a solid-state CO2 laser can reach 20,000 hours, glass laser tube can reach 3,000 hours. So you need to replace the CO2 laser tube every few years.

Learn more about fiber laser and CO2 laser and receptive laser machine

Post time: Aug-31-2022