Why Choose Lyocell?

Lyocell Fabric

Lyocell fabric (also known as Tencel Lyocell fabric) is an eco-friendly textile made of wood pulp from sustainable sources like eucalyptus. This fabric Lyocell is produced through a closed-loop process that recycles solvents, making it both soft and sustainable.

With excellent breathability and moisture-wicking properties, Lyocell fabric uses span from stylish clothing to home textiles, offering a durable, biodegradable alternative to conventional materials.

Whether you're looking for comfort or sustainability, what is Lyocell fabric becomes clear: a versatile, planet-conscious choice for modern living.

Introduction of Lyocell Fabric

Lyocell is a type of regenerated cellulose fiber made from wood pulp (typically eucalyptus, oak, or bamboo) through an eco-friendly solvent spinning process.

It belongs to the broader category of man-made cellulosic fibers (MMCFs), alongside viscose and modal, but stands out due to its closed-loop production system and minimal environmental impact.

1. Origins & Development

Invented in 1972 by American Enka (later developed by Courtaulds Fibers UK).

Commercialized in the 1990s under the brand Tencel™ (by Lenzing AG, Austria).

Today, Lenzing is the leading producer, but other manufacturers (e.g., Birla Cellulose) also produce Lyocell.

2. Why Lyocell?

Environmental Concerns: Traditional viscose production uses toxic chemicals (e.g., carbon disulfide), while Lyocell uses a non-toxic solvent (NMMO).

Performance Demand: Consumers sought fibers combining softness (like cotton), strength (like polyester), and biodegradability.

3. Why It Matters

Lyocell bridges the gap between natural and synthetic fibers:

Eco-friendly: Uses sustainably sourced wood, minimal water, and recyclable solvents.

High-performance: Stronger than cotton, moisture-wicking, and resistant to wrinkles.

Versatile: Used in apparel, home textiles, and even medical applications.

Comparison with Other Fibers

Lyocell vs. Cotton

| Property | Lyocell | Cotton |

| Source | Wood pulp (eucalyptus/oak) | Cotton plant |

| Softness | Silk-like, smoother | Natural softness, may stiffen over time |

| Strength | Stronger (wet & dry) | Weaker when wet |

| Moisture Absorption | 50% more absorbent | Good, but retains moisture longer |

| Environmental Impact | Closed-loop process, low water use | High water & pesticide use |

| Biodegradability | Fully biodegradable | Biodegradable |

| Cost | Higher | Lower |

Lyocell vs. Viscose

| Property | Lyocell | Viscose |

| Production Process | Closed-loop (NMMO solvent, 99% recycled) | Open-loop (toxic CS₂, pollution) |

| Fiber Strength | High (resists pilling) | Weak (prone to pilling) |

| Environmental Impact | Low toxicity, sustainable | Chemical pollution, deforestation |

| Breathability | Excellent | Good but less durable |

| Cost | Higher | Lower |

Lyocell vs. Modal

| Property | Lyocell | Modal |

| Raw Material | Eucalyptus/oak/bamboo pulp | Beechwood pulp |

| Production | Closed-loop (NMMO) | Modified viscose process |

| Strength | Stronger | Softer but weaker |

| Moisture Wicking | Superior | Good |

| Sustainability | More eco-friendly | Less sustainable than Lyocell |

Lyocell vs. Synthetic Fibers

| Property | Lyocell | Polyester |

| Source | Natural wood pulp | Petroleum-based |

| Biodegradability | Fully biodegradable | Non-biodegradable (microplastics) |

| Breathability | High | Low (traps heat/sweat) |

| Durability | Strong, but less than polyester | Extremely durable |

| Environmental Impact | Renewable, low-carbon | High carbon footprint |

Application of Lyocell Fabric

Apparel & Fashion

Luxury Clothing

Dresses & Blouses: Silk-like drape and softness for high-end women’s wear.

Suits & Shirts: Wrinkle-resistant and breathable for formal wear.

Casual Wear

T-shirts & Trousers: Moisture-wicking and odor-resistant for daily comfort.

Denim

Eco-Jeans: Blended with cotton for stretch and durability (e.g., Levi’s® WellThread™).

Home Textiles

Bedding

Sheets & Pillowcases: Hypoallergenic and temperature-regulating (e.g., Buffy™ Cloud Comforter).

Towels & Bathrobes

High Absorbency: Quick-drying and plush texture.

Curtains & Upholstery

Durable & Fade-Resistant: For sustainable home decor.

Medical & Hygiene

Wound Dressings

Non-Irritating: Biocompatible for sensitive skin.

Surgical Gowns & Masks

Breathable Barrier: Used in disposable medical textiles.

Eco-Friendly Diapers

Biodegradable Layers: Alternative to plastic-based products.

Technical Textiles

Filters & Geotextiles

High Tensile Strength: For air/water filtration systems.

Automotive Interiors

Seat Covers: Durable and sustainable alternative to synthetics.

Protective Gear

Fire-Resistant Blends: When treated with flame retardants.

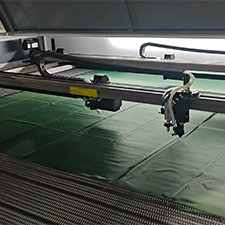

◼ Laser Cutting Fabric | Full Process!

In this video

This video records the entire process of laser cutting cloth. Watch the laser cutting machine accurately cut complex cloth patterns. This video shows real-time footage and embodies the advantages of "non-contact cutting", "automatic edge sealing" and "high efficiency and energy saving" in machine cutting.

Laser Cut Lyocell Fabric Process

Lyocell Compatibility

Cellulose fibers thermally decompose (not melt), producing clean edges

Naturally lower melting point than synthetics, reducing energy consumption.

Equipment Settings

The power is adjusted according to the thickness, usually lower than polyester. Fine patterns need to slow down to ensure the beam focusing accuracy. Ensure the beam focusing accuracy.

Cutting Process

Nitrogen assist minimizes edge discoloration

Brush removal of carbon residues

Post-Processing

Laser cutting uses a high-energy laser beam to vaporize fabric fibers precisely, with computer-controlled cutting paths enabling contactless processing of intricate designs.

Recommended Laser Machine For Lyocell Fabric

◼ Laser Engraving & Marking Machine

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

◼ Lyocell Fabric's AFQs

Yes, lyocell is considered a high-quality fabric due to its many desirable properties.

- Soft & Smooth – Feels silky and luxurious, similar to rayon or bamboo but with better durability.

- Breathable & Moisture-Wicking – Keeps you cool in warm weather by absorbing moisture efficiently.

- Eco-Friendly – Made from sustainably sourced wood pulp (usually eucalyptus) using a closed-loop process that recycles solvents.

- Biodegradable – Unlike synthetic fabrics, it breaks down naturally.

- Strong & Durable – Holds up better than cotton when wet and resists pilling.

- Wrinkle-Resistant – More so than cotton, though some light ironing may still be needed.

- Hypoallergenic – Gentle on sensitive skin and resistant to bacteria (good for people with allergies).

Initially yes (laser equipment costs), but saves long-term by:

Zero tooling fees (no dies/blades)

Reduced labor (automated cutting)

Minimal material waste

It’s neither purely natural nor synthetic. Lyocell is a regenerated cellulose fiber, meaning it’s derived from natural wood but processed chemically (though sustainably).

◼ Laser Cutting Machine

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm (62.9” * 39.3 ”)

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm (62.9” * 39.3 ”)