Laser Cutting Muslin Fabric

Introduction

What is Muslin Fabric?

Muslin is a finely woven cotton fabric with a loose, airy texture. Historically prized for its simplicity and adaptability, it ranges from sheer, gauzy variants to heavier weaves.

Unlike jacquard, muslin lacks woven patterns, offering a smooth surface ideal for printing, dyeing, and laser detailing.

Commonly used in fashion prototyping, theater backdrops, and baby products, muslin balances affordability with functional elegance.

Muslin Features

Breathability: Open weave allows airflow, perfect for warm climates.

Softness: Gentle against skin, suitable for infants and apparel.

Versatility: Takes dyes and prints well; compatible with laser engraving.

Heat Sensitivity: Requires low-power laser settings to avoid burning.

Muslin Bandage

History and Future Development

Historical Significance

Muslin originated in ancient Bengal (modern-day Bangladesh and India), where it was handwoven from premium cotton.

Renowned as the "cloth of kings," it was traded globally via the Silk Road. European demand in the 17th–18th centuries led to colonial exploitation of Bengali weavers.

Post-industrialization, machine-made muslin replaced handloom techniques, democratizing its use for everyday applications.

Future Trends

Sustainable Production: Organic cotton and recycled fibers are reviving eco-friendly muslin.

Smart Textiles: Integration with conductive threads for tech-enhanced garments.

3D Laser Techniques: Layered laser cutting to create 3D textures for avant-garde fashion.

Types

Sheer Muslin: Ultra-lightweight, used for draping and filters.

Heavyweight Muslin: Durable for quilting, curtains, and upholstery mockups.

Organic Muslin: Chemical-free, ideal for baby products and eco-conscious brands.

Blended Muslin: Mixed with linen or polyester for added strength.

Material Comparison

|

Fabric |

Weight |

Breathability |

Cost |

|

Sheer Muslin |

Very Light |

High |

Low |

|

Heavy Muslin |

Medium-Heavy |

Moderate |

Moderate |

|

Organic |

Light |

High |

High |

|

Blended |

Variable |

Moderate |

Low |

Muslin Applications

Muslin Sieves

Muslin Craft Fabric Squares

Muslin Stage Curtain

Fashion & Prototyping

Apparel Mockups: Lightweight muslin is the industry standard for creating garment prototypes.

Dyeing & Printing: Smooth surface ideal for fabric painting and digital printing.

Home & Decor

Theater Backdrops: Sheer muslin used for projection screens and stage curtains.

Quilting & Crafts: Heavyweight muslin serves as a stable base for quilting blocks.

Baby & Healthcare

Swaddles & Blankets: Soft, breathable organic muslin ensures baby comfort.

Medical Gauze: Sterilized muslin in wound care for its hypoallergenic properties.

Industrial Uses

Filters & Sieves: Open-weave muslin filters liquids in brewing or culinary applications.

Functional Characteristics

Dye Absorption: Holds natural and synthetic dyes vividly.

Fray Resistance: Laser-melted edges reduce unraveling in intricate cuts.

Layering Potential: Combines with lace or vinyl for textured designs.

Mechanical Properties

Tensile Strength: Moderate; varies with weave density.

Flexibility: Highly pliable, suitable for curved cuts.

Heat Tolerance: Sensitive; synthetic blends handle higher temperatures.

Printed Muslin Fabric

How to Cut Muslin Fabric?

CO₂ laser cutting is ideal for muslin fabric due to its precision, speed, and edge sealing capabilities. Its precision allows for delicate cuts without tearing the fabric.

The speed makes it efficient for bulk projects, such as apparel patterns. Additionally, the minimal heat exposure during the process prevents fraying, ensuring clean edges.

These features make CO₂ laser cutting a superior choice for working with muslin fabric.

Detailed Process

1. Preparation: Iron fabric to remove wrinkles; secure to the cutting bed.

2. Settings: Test power and speed on scraps.

3. Cutting: Use vector files for sharp edges; ensure ventilation for smoke.

4. Post-Processing: Wipe residue with a damp cloth; air-dry.

Muslin Mockup

Related Videos

How to Choose Laser Machine for Fabric

When selecting a laser machine for fabric, consider these key factors: material size and design complexity to determine the conveyor table, automatic feeding for roll materials.

Moreover, laser power and head configuration based on production needs, and specialized features like integrated marking pens for sewing lines and serial numbers.

What Can You Do with Felt Laser Cutter?

With a CO₂ laser cutter and felt, you can create intricate projects like ornaments, decorations, pendants, gifts, toys, table runners, and art pieces. For instance, laser-cutting a delicate butterfly from felt is a charming project.

Industrial applications benefit from the machine's versatility and precision, allowing for efficient production of items like gaskets and insulation materials. This tool enhances both hobbyist creativity and industrial efficiency.

Any Question to Laser Cutting Muslin Fabric?

Let Us Know and Offer Further Advice and Solutions for You!

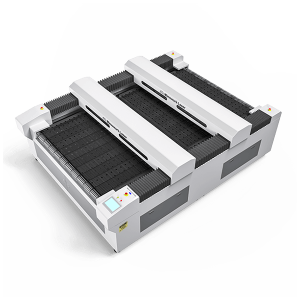

Recommended Muslin Laser Cutting Machine

At MimoWork, we specialize in cutting-edge laser cutting technology for textile production, with a particular focus on pioneering innovations in Muslin solutions.

Our advanced techniques tackle common industry challenges, ensuring impeccable outcomes for clients across the globe.

Laser Power: 100W/150W/300W

Working Area (W * L):1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power: 100W/150W/300W

Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

Laser Power: 150W/300W/450W

Working Area (W * L): 1600mm * 3000mm (62.9’’ *118’’)

FAQs

Cotton is prized for its softness and smoothness, making it a commonly used material for clothing, bedding, and other applications.

Muslin, on the other hand, has a slightly rougher texture but becomes softer over time with repeated washing.

This quality makes it highly favored for baby products, where comfort is a priority.

Muslin fabric is lightweight, breathable, and elegant, making it ideal for summer clothing and scarves.

However, it has some drawbacks, such as its tendency to wrinkle, which requires regular ironing.

Additionally, some types of muslin, like silk muslin, can be delicate and require special care due to their fragile nature.

Ironing or steaming muslin baby products can help remove wrinkles and give them a cleaner, crisper appearance if desired.

If you choose to do so, please follow these guidelines: When using an iron, set it to a low heat or delicate setting to prevent damage to the muslin fabric.