5 Things About Laser Welding (That you Missed)

Table of Content:

Intro:

In today's fast-paced manufacturing landscape, innovative technologies like laser welding are transforming the way fabrication is done.

From versatile 3-in-1 capabilities to blazing-fast speeds, this advanced technique offers a wealth of benefits that can revolutionize your production processes.

In this article, we'll delve into five key aspects of laser welding that you may have overlooked, empowering you to make the most of this cutting-edge technology.

3-in-1 Versatility in One Welder

From Laser Cutting, Laser Cleaning to Laser Welding

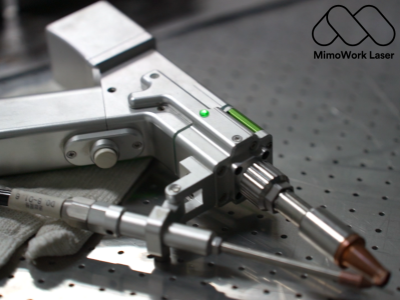

Many of today's state-of-the-art laser welding machines are designed to be true multi-taskers.

These 3-in-1 tools can not only perform high-precision laser welding but also function as laser cutters and laser cleaners.

By simply switching the mode and attaching a different nozzle, you can seamlessly transition between these three crucial fabrication processes.

All with a single machine.

This remarkable versatility allows you to streamline your workflow.

Reduce the need for multiple specialized machines, and ultimately save valuable time and resources.

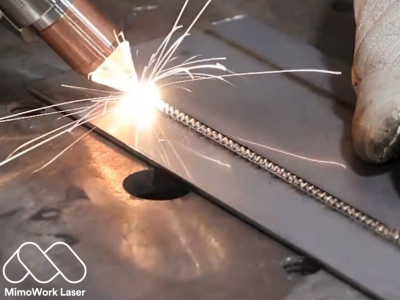

Precise Welding of Thin Materials

Intense, Targeted Heat with Tiny Heat-Affected Zone

One of the standout advantages of laser welding is its ability to work with thin materials with remarkable precision.

The laser's intense, targeted heat penetrates quickly, resulting in significantly less distortion and residual stress compared to traditional welding methods.

This means you can achieve super-durable welds with longer fatigue life, even when working with delicate or fragile metals.

Moreover, the tiny heat-affected zone ensures that you can weld these thin materials without worrying about warping or thermal damage.

Laser welding also allows you to join dissimilar materials that can be challenging to work with using conventional techniques.

Accessible for Everyone with Ease

For Both Novice and Experienced Welders

Laser welding is a technology that caters to welders of all skill levels.

For those new to the field, a handheld laser welder can be an excellent starting point.

These machines often come equipped with preset settings, allowing you to simply select the right program for your specific project.

Much like having pre-programmed cooking settings on your oven.

This user-friendly approach makes laser welding accessible and straightforward, even for those just beginning their welding journey.

On the other hand, experienced welders can also greatly benefit from incorporating a laser welding system into their workshop.

These advanced tools provide the ability to fine-tune the settings.

Allowing seasoned professionals to truly harness the full potential of this technology.

By leveraging the precision and control offered by laser welding.

Experienced users can optimize their fabrication processes and achieve unparalleled results.

Laser Welding is the Future. And the Future Starts with You!

Blazing-Fast Welding Speeds

On Average, Weld Up to Four Times Faster with a Laser

Another remarkable advantage of laser welding is its exceptional speed.

On average, you can weld up to four times faster with a laser compared to traditional TIG welding methods.

This increased efficiency can have a significant impact on your productivity and turnaround times.

Additionally, laser welding systems offer the flexibility to switch between pulsed and continuous welding modes, further enhancing your control and precision.

For instance, the pulsed mode is particularly useful when welding stainless steel pipes, allowing you to maintain a higher level of control over the process.

Shielding Gas Optimization

For Cost Savings in the Long Run

Finally, did you know that you can potentially save money on shielding gas by switching from Argon to Nitrogen in certain applications?

This strategic swap can be particularly beneficial when welding materials like Steel, Stainless Steel, Nickel Alloys, and Copper.

With the rising costs of Argon, this simple adjustment can add up to significant savings over time.

Further enhancing the cost-effectiveness of your laser welding operations.

Video Version: 5 Things About Laser Welding (That you Missed)

Laser welding is a versatile and advanced technology that has transformed the welding industry.

Beyond its core function of creating strong, durable welds, this cutting-edge technique offers a range of unique benefits.

These are five key aspects of laser welding that you may have overlooked.

Shedding light on why it's becoming the go-to choice for both new and experienced welders alike.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Video: Laser Welding Vs TIG Welding: Which one is Better?

This video offers an unexpected comparison between TIG and laser welding,

taking into account factors like pre-welding cleaning, the cost of shielding gas for both processes, and welding strength.

As laser welding is relatively new, there are some misconceptions about it.

In reality, not only is laser welding easier to learn, but with the appropriate wattage, it can match the capabilities of TIG welding.

With the right technique and power settings, welding stainless steel or aluminum becomes quite straightforward.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Conclusion

A Truly Remarkable Technology with Power to Elevate to New Heights

By understanding these five often overlooked aspects, you can unlock a world of possibilities.

From versatile 3-in-1 capabilities and precise thin material welding to accessibility for welders of all skill levels and blazing-fast speeds.

And with the potential to optimize your shielding gas usage.

Laser welding presents a compelling opportunity to streamline your operations and enhance your bottom line.

As you embark on your welding journey, be sure to harness the full potential of this transformative technology.

Machine Recommendations for Laser Welding

Here are some Laser-Knowledge you Might be Interested in:

Post time: Jul-19-2024