7 Ideas of Laser Cut Woodworking!

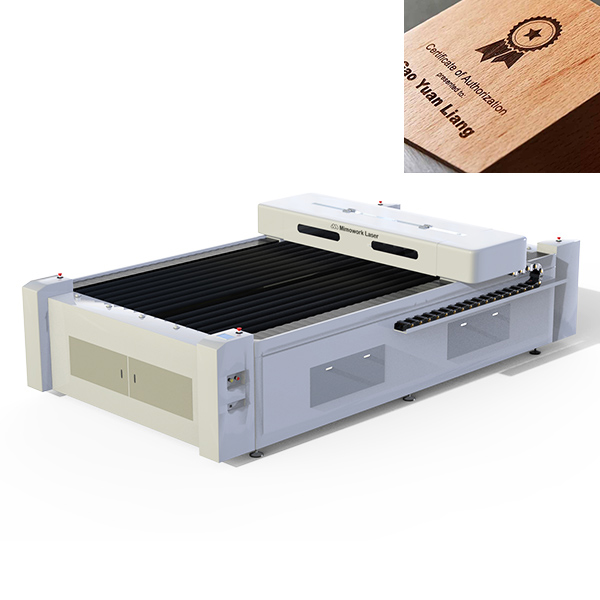

laser cutting machine for Plywood

Laser cut woodworking has gained popularity across various industries, from crafts and ornaments to architectural models, furniture, and more. Thanks to its cost-effective customization, highly precise cutting and engraving capabilities, and compatibility with a wide range of wood materials, woodworking laser cutting machines are ideal for creating detailed wood designs through cutting, engraving, and marking. Whether you’re a hobbyist or a professional woodworker, these machines offer unmatched convenience.

What’s even more exciting is the speed—laser cutting and engraving wood is incredibly fast, allowing you to turn your ideas into reality with rapid prototyping.

In this article, I'll also address common questions about laser cutting wood, such as: How thick can a laser cut through wood? What types of wood are suitable? And which wood laser cutters are recommended? If you’re curious, stick around—you’ll find the answers you need!

1. Laser Cut Wood Ornaments

Laser cutting machines are ideal for creating intricate wooden ornaments, whether for holiday decorations or year-round decor.

The precision of a laser allows for delicate designs, like snowflakes, stars, or personalized shapes, that would be difficult to achieve with traditional tools.

These ornaments can be used to decorate homes, gifts, or special events.

Check out the video to witness the excellent ability to handle fine and complex details.

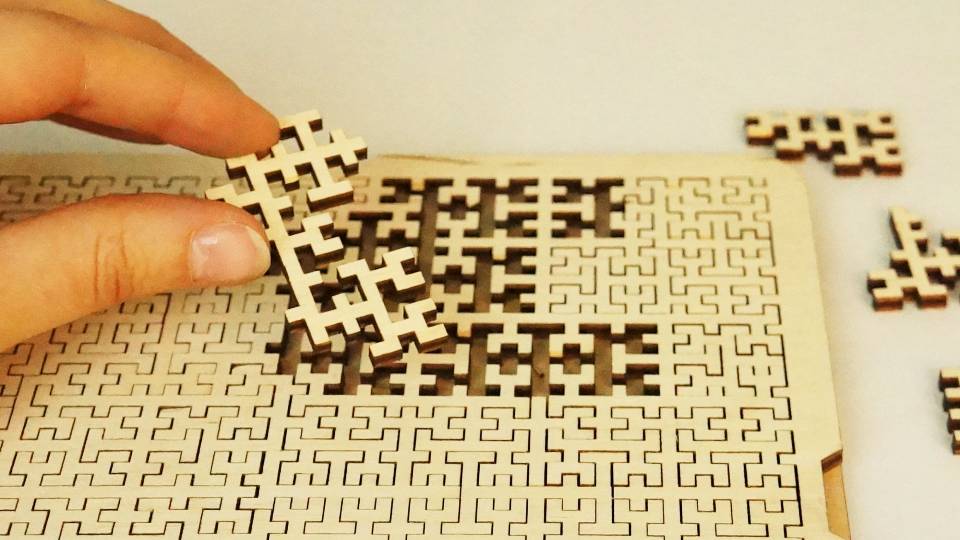

2. Laser Cut Wood Models

Laser cutting is a game-changer for creating precise and detailed models.

Whether you're into architectural models, scale models of vehicles, or creative 3D puzzles, a laser cutting machine simplifies the process by cutting clean, sharp edges in various thicknesses of wood.

This is perfect for hobbyists or professionals who need to create accurate, repeatable designs.

We ever used a piece of basswood and a woodworking laser cutting machine, to make an Eiffel Tower Model. The laser cut some wood pieces and we assemble them into a complete model, like wood puzzles. That is interesting. Check out the video, and enjoy the fun of laser wood!

3. Laser Cut Wood Furniture

For a more ambitious project, laser cutting machines can be used to customize table surfaces or components with intricate engravings or patterns.

Unique designs can be engraved into the tabletop or even cut-out sections for adding creative elements, making each piece of furniture one of a kind.

Besides the stunning laser cutting, the wood laser machine can engrave on the furniture surface and create exquisite markings like patterns, logos, or text.

In this video, we make a small wood table and engrave a pattern of tiger on it.

4. Laser Engraved Wood Coaster

Coasters are one of the most popular and practical items you can make with a laser cutter. You can create customized designs for restaurants, cafes, or even personalized home gifts.

Laser engraving adds a touch of elegance by adding logos, names, or intricate patterns. This is a great example of how even small items can be a testament to the precision and versatility of laser cutting machines.

A quick video of coaster production, from design to finished product.

5. Laser Wood Photo Engraving

One of the most impressive uses of a laser cutter is photo engraving on wood.

Laser technology can accurately reproduce a photograph’s depth and detail on wooden surfaces, creating memorable, personalized gifts or artistic pieces.

This idea can attract attention from those looking to offer sentimental gifts or artists who want to explore new mediums.

Interested in the engraving ideas, glance at the video to find more.

6. Laser Cut Photo Frame

Pairing a photo engraving with a custom-made frame is a great way to make the perfect gift or home decor.

Laser cutting is sharp and precise to handle customized photo frames. Any shape, any design, you can create exquisite photo frames in unique styles. Woodworking laser cutting machines can craft beautifully detailed and personalized frames, allowing you to engrave names, messages, or patterns directly onto the frame.

These frames can be sold as personalized gifts or home accessories. A video demonstrating the making of a photo frame from start to finish can add an engaging visual element to this section.

7. Laser Cut Wood Signage

Wooden signs are another creative application for laser cutting machines.

Whether for business, home decor, or events, laser-cut wooden signs offer a rustic, yet professional look. You can create everything from large exterior signs to intricate interior signage with ease, thanks to the precision of a laser machine.

More Ideas >>

What are Your Laser Wood Ideas? Share Your Insights with Us

FAQ of Laser Cut Woodworking

1. What thickness plywood can a laser cut?

In general, the woodworking laser cutting machine can cut through 3mm - 20mm thick wood. Fine laser beam of 0.5mm can achieve precise wood cutting like veneer inlay, and is powerful enough to cut through thick wood maximum of 20mm.

2. How to find the right focus for laser cutting plywood?

For adjusting the focus length for laser cutting, MimoWork designed the auto-focus device and auto-lifting laser cutting table, to assist you find the optimal focus length for materials to be cut.

Besides, we made a video tutorial to step by step instruct how to determine the focus. Check this out.

3. What are the advantages of laser cutting woodworking?

• Precision: Allows for highly detailed cuts and engravings.

• Versatility: Works on a wide variety of wood types.

• Customization: Easily switch between designs for unique or batch projects.

• Speed: Faster and more efficient than traditional cutting methods.

• Minimal Waste: Precise cuts reduce material waste.

• Non-contact: No tool wear and less risk of damage to the wood.

4. What are the disadvantages of laser cutting woodworking?

• Cost: High initial investment for the machine.

• Burn Marks: Can leave charring or burn marks on the wood.

• Thickness Limits: Not ideal for cutting very thick wood.

5. How to operate the woodworking laser cutting machine?

It's easy to operate the laser machine. CNC control system give it high automation. You just need to complete the three steps, and for others the laser machine can finish them.

Step 1. Prepare the wood and put it on the laser cutting table.

Step 2. Import your design file of woodworking into laser cutting software, and set laser parameters like speed and power.

(After you buy the machine, our laser expert will recommend suitable parameters to you in terms of your cutting requirements and materials.)

Step 3. Press the start button, and the laser machine starts cutting and engraving.

If you have any questions about laser cutting wood, talk with us!

If you are interested in the woodworking laser machine, go on the recommendation ⇨

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2000mm/s

• Mechanical Control System: Step Motor Belt Control

• Working Area: 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 150W/300W/450W

• Max Cutting Speed: 600mm/s

• Position Accuracy: ≤±0.05mm

• Mechanical Control System: Ball Screw & Servo Motor Drive

How to select a suitable woodworking laser cutting machine?

Related News

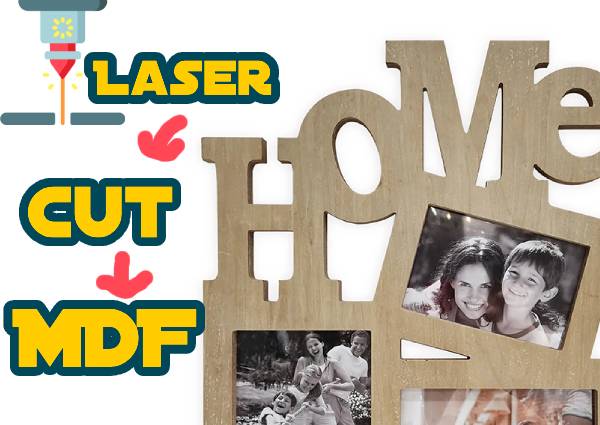

MDF, or Medium-Density Fiberboard, is a versatile and widely used material in furniture, cabinetry, and decorative projects. Due to its uniform density and smooth surface, it's an excellent candidate for various cutting and engraving methods. But can you laser cut MDF?

We know laser is a versatile and powerful processing method, can handle many precise tasks in different fields like insulation, fabric, composites, automotive, and aviation. But how about laser cutting wood, particularly laser cutting MDF? Is it feasible? How is the cutting effect? Can you laser engrave MDF? What laser cutting machine for MDF should you choose?

Let's explore the suitability, effects, and best practices for laser cutting and engraving MDF.

Pine, Laminated Wood, Beech, Cherry, Coniferous Wood, Mahogany, Multiplex, Natural Wood, Oak, Obeche, Teak, Walnut and more.

Almost all wood can be laser cut and the laser cutting wood effect is excellent.

But if your wood to be cut adhered to toxic film or paint, safety precaution is necessary while laser cutting.

If you are not sure, inquire with a laser expert is the best.

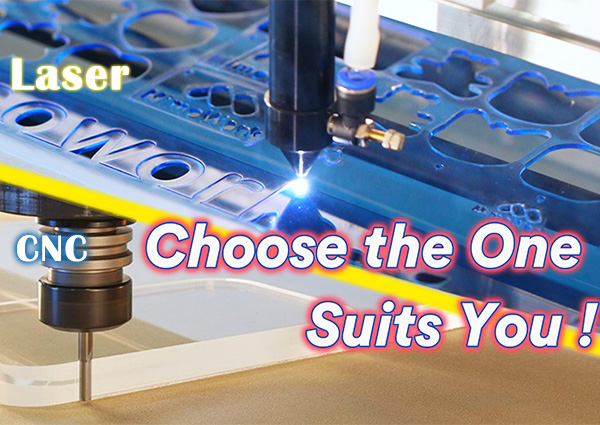

When it comes to acrylic cutting and engraving, CNC routers and lasers are often compared.

Which one is better?

The truth is, they are different but complement each other by playing unique roles in different fields.

What are these differences? And how should you choose? Get through the article and tell us your answer.

Any Questions about Laser Cut Woodworking?

Post time: Sep-06-2024