Applique Laser Cutting Machine

How To Laser Cut Applique Kits?

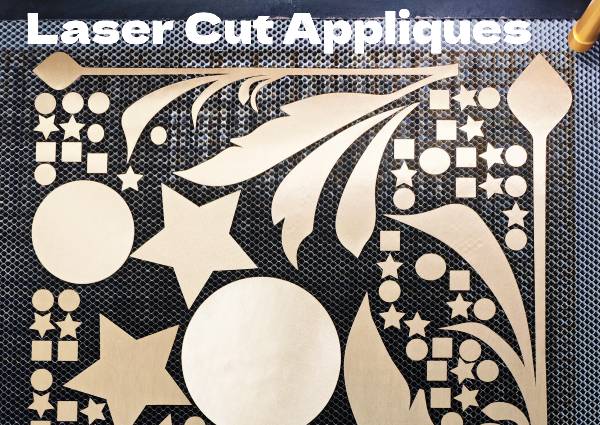

Appliqués play a vital role in fashion, home textiles, and bag design. Essentially, you take a piece of fabric or leather and place it on top of your base material, then sew or glue it down.

With laser-cut appliqués, you get a quicker cutting speed and a smoother workflow, especially for those intricate designs. You can create various shapes and textures that can enhance clothing, signage, event backdrops, curtains, and crafts.

Not only do these laser-cut kits add beautiful details to your projects, but they also boost your production efficiency, making it easier to bring your creative ideas to life!

What You Can Get from Laser Cut Appliques

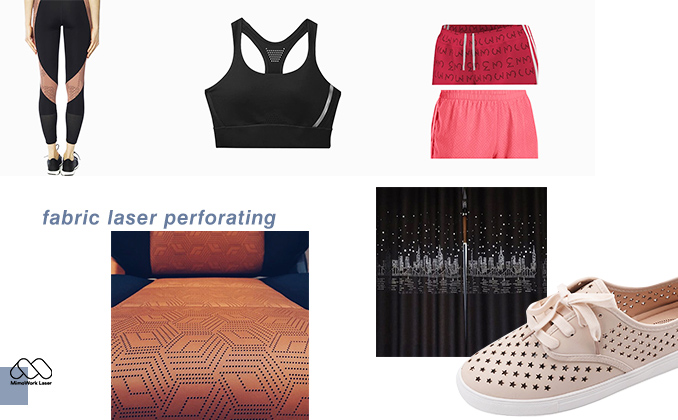

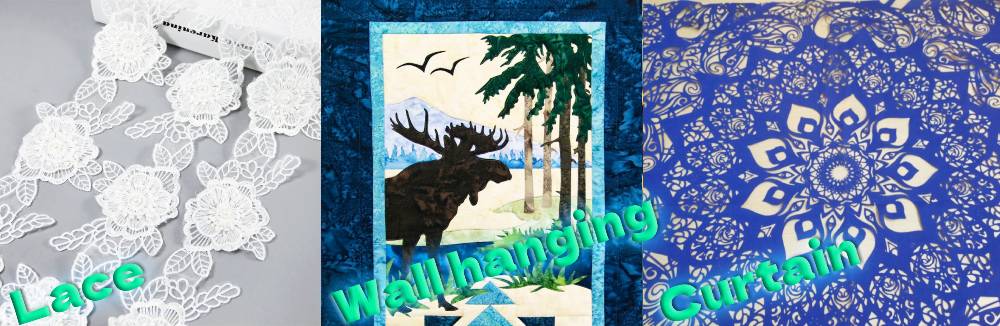

Laser cutting fabric appliqués brings a whole new level of precision and creative freedom, making it perfect for all sorts of projects. In fashion, it adds stunning details to clothing, accessories, and shoes. When it comes to home décor, it personalizes items like pillows, curtains, and wall art, giving each piece a unique flair.

For quilting and crafting enthusiasts, detailed appliqués enhance quilts and DIY creations beautifully. This technique is also fantastic for branding—think custom corporate apparel or sports team uniforms. Plus, it’s a game changer for creating intricate costumes for theater productions and personalized decorations for weddings and parties.

Overall, laser cutting elevates the visual appeal and uniqueness of products across many industries, making every project a little more special!

Unleash Your Appliques Creativity with Laser Cutter

▽

Popular Applique Laser Cutting Machine

If you're diving into appliqué making as a hobby, the Appliqué Laser Cutting Machine 130 is a fantastic choice! With a spacious 1300mm x 900mm working area, it can handle most appliqué and fabric cutting needs effortlessly.

For printed appliqués and lace, consider adding a CCD Camera to your flatbed laser cutting machine. This feature allows for precise recognition and cutting of printed contours, ensuring your designs come out perfectly. Plus, this compact machine can be fully customized to fit your specific needs and budget. Happy crafting!

Machine Specification

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Options: Upgrade Appliques Production

Auto Focus

You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the optimal focus distance to material surface.

Servo Motor

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position.

The CCD Camera is the eye of applique laser cutting machine, recognizing the patterns's position and directing the laser head to cut along the contour. That's significant for cutting printed appliques, ensuring the accuracy of pattern cutting.

You Can Make Various Appliques

With the applique laser cutting machine 130, you can make tailor-made applique shapes and patterns with different materials. Not only for solid fabric patterns, the laser cutter is suitable for laser cutting embroidery patches and printed materials like stickers or film with the help of the CCD Camera system. The software also supports mass production for appliques.

Learn More about the

Applique Laser Cutter 130

The Mimowork’s Flatbed Laser Cutter 160 is mainly for cutting roll materials. This model is especially R&D for soft materials cutting, like textile and leather laser cutting. You can choose different working platforms for different materials. Moreover, two laser heads and the auto feeding system as MimoWork options are available for you to achieve higher efficiency during your production. The enclosed design from fabric laser cutting machine ensures the safety of laser use.

Machine Specification

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Options: Upgrade Foam Production

Dual Laser Heads

In the simplest and most economic way to speed up your production efficiency is to mount multiple laser heads on the same gantry and cut the same pattern simultaneously. This doesn't take extra space or labor.

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you.

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system.

You Can Make Various Appliques

The applique laser cutting machine 160 enables large format materials cutting, like lace fabric, curtain appliques, walling hanging, and backdrop, garment accessories. Precise laser beam and agile laser head moving offer exquisite cutting quality even if for large-size patterns. Continuous cutting and heat sealing processes guarantee a smooth pattern edge.

Upgrade Your Appliques Production with Laser Cutter 160

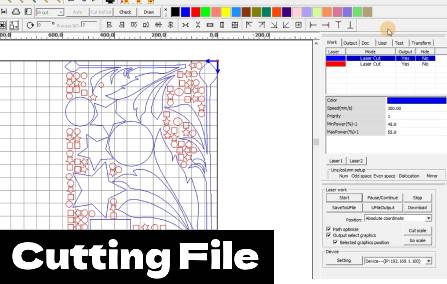

Step1. Import the Design File

Import it into the laser system and set the cutting parameters, the applique laser cutting machine will cut the appliques according to the design file.

Step2. Laser Cutting Appliques

Start the laser machine, the laser head will move to the right position, and start the cutting process according to the cutting file.

Step3. Collect the Pieces

After the fast laser cutting appliques, you just take away the whole fabric sheet, the rest of the pieces will be left alone. No any adherence, no any burr.

Video Demo | How to Laser Cut Fabric Appliques

We used a CO2 laser cutter to create fabric appliqués using a gorgeous glamour fabric—think luxurious velvet with a matte finish. This powerful machine, with its precise laser beam, delivers high-precision cutting, bringing out exquisite pattern details.

If you’re looking to make pre-fused laser-cut appliqué shapes, just follow the steps below for laser cutting fabric. This process is not only flexible but also automated, allowing you to customize a variety of patterns—from laser-cut designs and flowers to unique fabric accessories.

It’s easy to operate and produces delicate, intricate cutting effects. Whether you're a hobbyist working with appliqué kits or involved in fabric upholstery production, the fabric appliqués laser cutter will be your go-to tool!

Laser Cutting Backdrop

Laser cutting backdrop appliqués is an innovative and efficient way to craft beautiful, detailed decorative elements for various events and settings. With this technique, you can create intricate fabric or material pieces that add a unique touch to your backdrops.

These backdrops are perfect for events, photography, stage designs, weddings, and anywhere you want a visually stunning background. The precision of laser cutting ensures high-quality designs that truly enhance the overall aesthetic of the space, making every occasion even more special!

Laser Cutting Sequin Appliques

Laser cutting sequin fabric is a sophisticated technique that allows for the creation of detailed and intricate designs on sequined materials. By using a high-powered laser, this method precisely cuts through both the fabric and the sequins, resulting in beautiful shapes and patterns.

This enhances the visual appeal of various accessories and decorative items, adding a touch of elegance and uniqueness to your projects.

Laser Cutting Interior Ceiling

Using laser cutting to create appliqués for interior ceilings is a modern and creative approach to enhancing interior design. This technique involves the precise cutting of materials like wood, acrylic, metal, or fabric to produce intricate and customized designs that can be applied to ceilings, adding a unique and decorative touch to any space.

• Can Laser Cut Fabric?

Yes, the CO2 laser has a significant wavelength advantage, making it highly effective for cutting most fabrics and textiles. This results in an excellent cutting effect, as the precise laser beam can create exquisite and intricate patterns on the material.

This capability is one reason why laser-cut appliqués are so popular and efficient for upholstery and accessories. Additionally, the heat generated during the cutting process helps to seal the edges, resulting in clean and finished edges that enhance the overall quality of the final product.

• What is Pre-Fused Laser Cut Applique Shapes?

Pre-fused laser cut appliqué shapes are decorative fabric pieces that have been precisely cut using a laser and feature a fusible adhesive backing.

This design allows for easy application—simply iron them onto a base fabric or garment without the need for additional adhesive or complex sewing techniques. This convenience makes them ideal for crafters and designers looking to add intricate designs quickly and efficiently!

Get Benefits and Profits from Applique Laser Cutter

Talk with Us to Learn More

Any Questions about Laser Cutting Appliques?

Post time: May-20-2024