Stone Engraving Laser: You Need to Know

for stone engraving, marking, etching

Laser engraving stone is a popular and convenient method to engrave or mark stone products.

People use the stone laser engraver to add value to their stone products and crafts, or distinguish them among the market. Such as:

- • Coasters

- • Ornaments

- • Accessories

- • Jewelry

- • And more

Why do people love the stone laser engraving?

Unlike mechanical processing (such as drilling or CNC routing), laser engraving (also known as laser etching) uses a modern, non-contact method.

With its precise and delicate touch, a powerful laser beam can etch and engrave on the stone surface, and leave intricate and fine marks.

Laser is like an elegant dancer with both flexibility and strength, leaving beautiful footprints wherever it goes on stone.

If you’re interested in the process of stone engraving laser and want to learn more about this fascinating technology, join us as we explore the magic of laser stone engraving!

Can You Laser Engrave Stone?

Yes, absolutely!

The laser can engrave stone.

And you can use a professional stone laser engraver to engrave, mark, or etch on various stone products.

We know there are various stone materials like slate, marble, granite, pebble, and limestone.

Whether they all can be laser engraved?

① Well, almost all stones can be laser engraved with great engraving details. But for various stones, you need to choose specific laser types.

② Even for the same stone materials, there are differences in material characteristics like moisture level, metal content, and porous structure.

So we strongly recommend you choose a reliable laser engraver supplier cause they can offer you expert tips to smooth your stone production and business, whether you are a beginner or a laser pro.

Video Display:

Laser Distinguishes Your Stone Coaster

Stone coasters, especially slate coasters are very popular!

Aesthetic appeal, durability, and heat resistance. They are often considered upscale and are frequently used in modern and minimalist decor.

Behind the exquisite stone coasters, there is laser engraving technology and our loved stone laser engraver.

Via dozens of tests and improvements in laser technology, the CO2 laser is verified to be great for slate stone in engraving effect and engraving efficiency.

So what stone are you working with? What laser is the most suitable?

Keep reading to find out.

What Stone is Suitable for Laser Engraving?

What Stone is Less Suitable for Laser Engraving?

When choosing suitable stones for laser engraving, there are some material physical properties you need to consider:

- • Smooth and flat surface

- • Hard texture

- • Less porosity

- • Low moisture

These material properties make the stone favorable to laser engraving. Finished with great engraving quality within a proper time.

By the way, even though it's the same type of stone, you better check the material first and test, that will protect your stone laser engraver, and not delay your production.

Benefits from Laser Stone Engraving

There are many ways to engrave stone, but the laser is unique.

Then what is the special for laser engraving stone? And what benefits do you get from it?

Let's talk about.

Versatility & Flexibility

(higher cost performance)

Speaking of the advantages of laser stone engraving, the versatility and flexibility are the most fascinating.

Why say that?

For most people who are engaged in the stone product business or artwork, trying different styles and replacing stone materials are their important needs, so that their products and works can adapt to various market demands, and follow the trends promptly.

Laser, just satisfies their needs.

On the one hand, we know the stone laser engraver suits different types of stones. That offers convenience if you are gonna expand the stone business. For example, if you are in the tombstone industry, but have an idea to expand a new production line - slate coaster business, in this case, you do not need to replace the stone laser engraving machine, you just need to replace the material. That's so cost-effective!

On the other hand, the laser is free and flexible in turning the design file into reality. What does that mean? You can use the stone laser engraver to engrave logos, text, patterns, photos, pictures, and even QR codes or barcodes on stone. Whatever you design, the laser can always make it. It is the creator's lovely partner and inspiration realizer.

Striking Precision

(exquisite engraving quality)

Super-high precision in the engraving is another advantage of a stone laser engraver.

Why should we value the engraving precision?

In general, the fine details and rich layering of the picture come from the printing accuracy, that is, dpi. Similarly, for the laser engraving stone, higher dpi usually brings more precise and richer details.

If you want to engrave or carve a photograph like a family photo, 600dpi is an appropriate choice for engraving on stone.

Besides the dpi, the diameter of the laser spot has an impact on the image engraved.

A thinner laser spot, can bring more sharp and clear marks. Combined with the higher power, the sharp engraved mark is permanent to be visible.

The precision of laser engraving is perfect for creating intricate designs that wouldn't be possible with traditional tools. For instance, you could engrave a beautiful, detailed image of your pet, a complex mandala, or even a QR code that links to your website.

No Wear and Tear

(cost-saving)

Stone engraving laser, there is no abrasion, no wear to the material and the machine.

That's different from the traditional mechanical tools like drill, chisel or cnc router, where the tool abrasion, stress on the material are happening. You also replace the router bit and drill bit. That is time-consuming, and more importantly, you have to keep paying for the consumables.

However, laser engraving is different. It's a non-contact processing method. No mechanical stress from direct contact.

That means the laser head keeps well-performing in the long term, you don't replace it. And for the material to be engraved, no crack, no distortion.

High Efficiency

(more output in a short time)

Laser etching stone is a fast and easy process.

① The stone laser engraver features powerful laser energy and agile moving speed. The laser spot is like a high-energy fireball, and can remove the part of surface material based on the engraving file. And quickly move to the next mark to be engraved.

② Due to the automatic process, it is easy for the operator to create various exquisite engraved patterns. You just import the design file, and set parameters, the rest of the engraving is the laser's task. Free up your hands and your time.

Think of laser engraving as using a super-precise and super-fast pen, while traditional engraving is like using a hammer and chisel. It’s the difference between drawing a detailed picture and carving one out slowly and carefully. With lasers, you can create that perfect picture every time, quickly and easily.

Popular Applications: Laser Engraving Stone

Stone Coaster

◾ Stone coasters are popular for their aesthetic appeal, durability, and heat resistance, being used in bars, restaurants, and homes.

◾ They are often considered upscale and are frequently used in modern and minimalist decor.

◾ Made from various stones such as slate, marble, or granite. Among them, the slate coaster is the most popular.

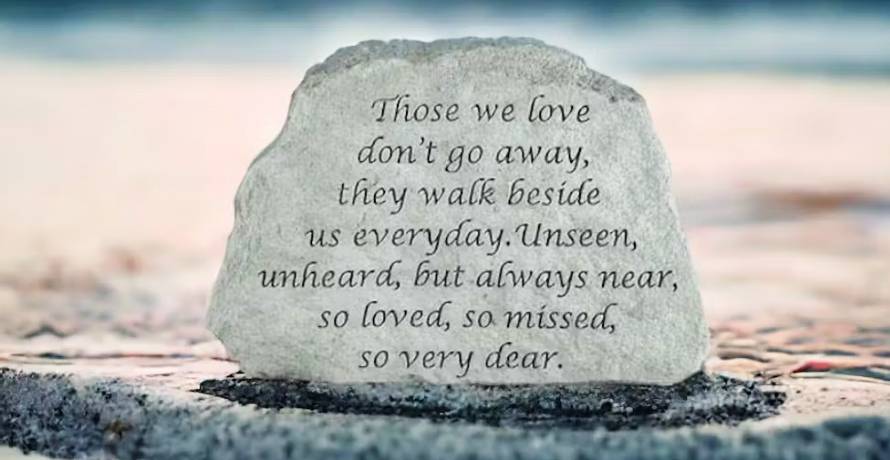

Memorial Stone

◾ The memorial stone can be engraved and marked with greeting words, portraits, names, events, and first moments.

◾ The unique texture and material style of the stone, combined with the carved text, convey a solemn and dignified feeling.

◾ Engraved headstones, grave markers, and tribute plaques.

Stone Jewelry

◾ Laser-engraved stone jewelry offers a unique and lasting way to express personal style and sentiment.

◾ Engraved pendants, necklaces, rings, etc.

◾ Suitable stone for jewelry: quartz, marble, agate, granite.

Stone Signage

◾ Using laser-engraved stone signage is unique and eye-catching for shops, work studios, and bars.

◾ You can engrave a logo, name, address, and some customized patterns on the signage.

Stone Paperweight

◾ Branded logo or stone quotations on paperweights and desk accessories.

Recommended Stone Laser Engraver

CO2 Laser Engraver 130

CO2 laser is the most common laser type for engraving and etching stones.

The Mimowork’s Flatbed Laser Cutter 130 is mainly for laser cutting and engraving solid materials like stone, acrylic, wood.

With the option equipped with a 300W CO2 laser tube, you can try the deep engraving on the stone, creating a more visible and clear mark.

The two-way penetration design allows you to place materials that extend beyond the working table width.

If you want to achieve high-speed engraving, we can upgrade the step motor to DC brushless servo motor and reach the engraving speed of 2000mm/s.

Machine Specification

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Fiber laser is an alternative to CO2 laser.

The fiber laser marking machine uses fiber laser beams to make permanent marks on the surface of various materials including stone.

By evaporating or burning off the surface of the material with light energy, the deeper layer reveals then you can get a carving effect on your products.

Machine Specification

| Working Area (W * L) | 70*70mm, 110*110mm, 175*175mm, 200*200mm (optional) |

| Beam Delivery | 3D Galvanommeter |

| Laser Source | Fiber Lasers |

| Laser Power | 20W/30W/50W |

| Wavelength | 1064nm |

| Laser Pulse Frequency | 20-80Khz |

| Marking Speed | 8000mm/s |

| Repetition Precision | within 0.01mm |

Which Laser is Suitable for Engraving Stone?

CO2 LASER

Advantages:

① Wide versatility.

Most stones can be engraved by CO2 laser.

For example, for engraving quartz with reflective properties, CO2 laser is the only to make it.

② Rich engraving effects.

CO2 laser can realize diverse engraving effects and different engraving depths, on one machine.

③ Larger working area.

CO2 stone laser engraver can handle larger formats of stone products to finish engraving, like gravestones.

(We tested stone engraving to make a coaster, using a 150W CO2 stone laser engraver, the efficiency is the highest compared with the fiber at the same price.)

Disadvantages:

① Large machine size.

② For small and extremely fine patterns like portraits, fiber sculpts better.

FIBER LASER

Advantages:

① Higher precision in engraving and marking.

Fiber laser can create very detailed portrait engraving.

② Fast speed for light marking and etching.

③ Small machine size, making it space-saving.

Disadvantages:

① The engraving effect is limited to shallow engraving, for a lower-power fiber laser marker like 20W.

Deeper engraving is possible but for multiple passes and a longer time.

② The machine price is so expensive for higher power like 100W, compared with CO2 laser.

③ Some stone types can not be engraved by fiber laser.

④ Due to the small working area, the fiber laser can not engrave larger stone products.

DIODE LASER

Diode laser is not suitable for engraving stone, due to its lower power, and simper exhaust device.

FAQ

• Can Quartz be Laser Engraved?

The quartz is possible to be engraved by laser. But you need to choose a CO2 laser stone engraver

Due to the reflective property, other laser types are not suitable.

• What Stone is Suitable for Laser Engraving?

In general, a polished surface, flat, with less porosity, and lower moisture of stone, has a great engraved performance for laser.

What stone is not suitable for laser, and how to choose, click here to learn more >>

• Can Laser Cut Stone?

Laser cutting stone is not typically feasible with standard laser cutting systems. Cause its hard, dense texture.

However, laser engraving and marking stone is a well-established and effective process.

For cutting stones, you can choose diamond blades, angle grinders, or waterjet cutters.

Any Questions? Talk with Our Laser Experts!

More About Laser Engraving Stone

Post time: Jun-11-2024