Can You Laser Cut MDF?

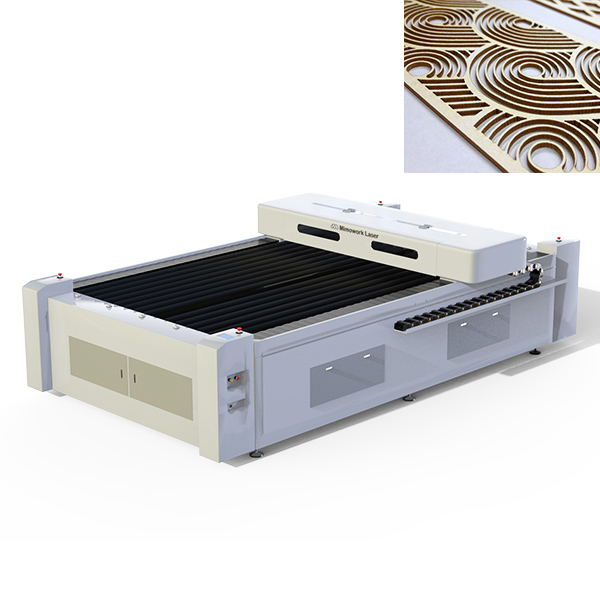

laser cutting machine for MDF board

MDF, or Medium-Density Fiberboard, is a versatile and widely used material in furniture, cabinetry, and decorative projects. Due to its uniform density and smooth surface, it's an excellent candidate for various cutting and engraving methods. But can you laser cut MDF?

We know laser is a versatile and powerful processing method, can handle many precise tasks in different fields like insulation, fabric, composites, automotive, and aviation. But how about laser cutting wood, particularly laser cutting MDF? Is it feasible? How is the cutting effect? Can you laser engrave MDF? What laser cutting machine for MDF should you choose?

Let's explore the suitability, effects, and best practices for laser cutting and engraving MDF.

Can You Laser Cut MDF?

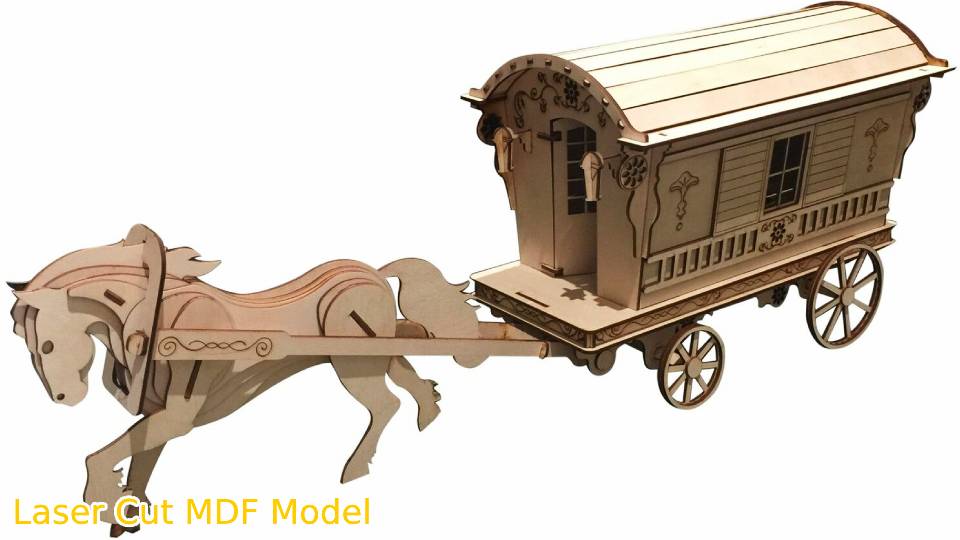

Firstly, the answer to laser cutting MDF is YES. The laser can cut MDF boards, and create rich and intricate designs for them Many crafters and businesses have been using laser cutting MDF to put on production.

But to clear up your confusion, we need to start from the properties of MDF and laser.

What is MDF?

MDF is made from wood fibers bonded with resin under high pressure and heat. This composition makes it dense and stable, which makes it suitable for cutting and engraving.

And the cost of MDF is more affordable, compared with other wood like plywood and solid wood. So it's popular in furniture, decoration, toy, shelving, and crafts.

What is Laser Cutting MDF?

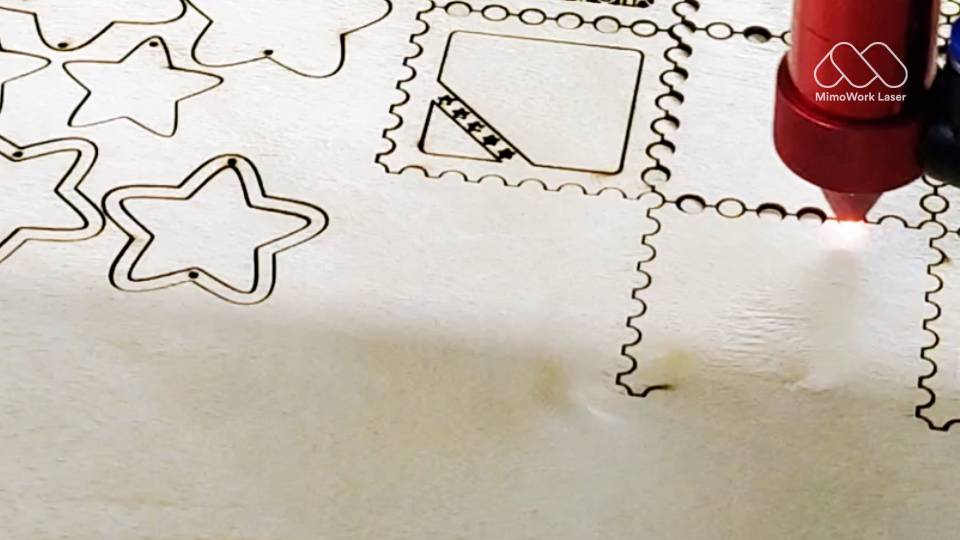

The laser focuses intense heat energy onto a small area of the MDF, heating it to the point of sublimation. So there is little debris and fragments left. The cutting surface and surrounding area are clean.

Due to the strong power, the MDF will be directly cut through where the laser passes.

The most special feature is the non-contact, which is different from most cutting methods. Depending on the laser beam, the laser head never needs to touch the MDF.

What does that mean?

There is no mechanical stress damage to the laser head or MDF board. Then you will know why people praise the laser as a cost-effective and clean tool.

Just like laser surgery, laser cutting MDF is highly precise and ultra fast. A fine laser beam passes through the MDF surface, producing a thin kerf. That means you can use it to cut intricate patterns for decorations and crafts.

Due to the features of MDF and Laser, the cutting effect is clean and smooth.

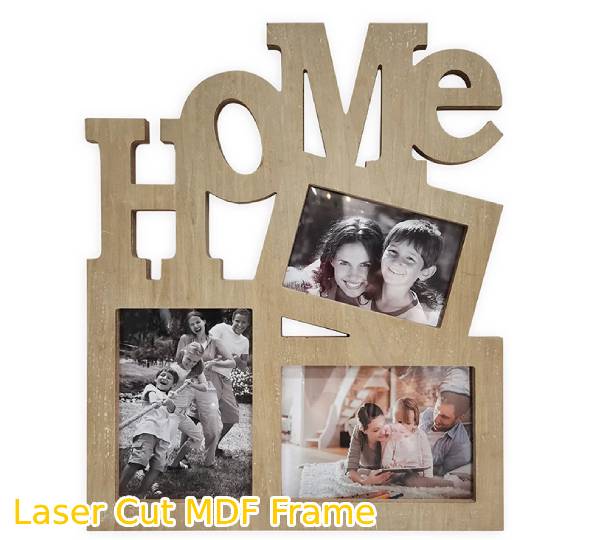

We have used the MDF to make a photo frame, it's exquisite and vintage. Interested in that, check out the video below.

◆ High Precision

Laser cutting provides exceptionally fine and accurate cuts, allowing for intricate designs and detailed patterns that would be difficult to achieve with traditional cutting tools.

◆ Smooth Edge

The laser's heat ensures that the cut edges are smooth and free of splinters, which is particularly beneficial for decorative and finished products.

◆ High Efficient

Laser cutting is a fast process, capable of cutting through MDF quickly and efficiently, making it suitable for both small-scale and large-scale production.

◆ No Physical Wear

Unlike saw blades, the laser does not physically contact the MDF, meaning there is no wear and tear on the cutting tool.

◆ Max Material Utilization

The precision of laser cutting minimizes material wastage, making it a cost-effective method.

◆ Customized Design

Capable of cutting complex shapes and patterns, laser cutting MDF can accomplish projects that would be difficult for you to accomplish with traditional tools.

◆ Versatility

Laser cutting is not limited to simple cuts; it can also be used for engraving and etching designs onto the surface of MDF, adding a layer of customization and detail to projects.

1. Furniture Making: For creating detailed and intricate components.

2. Signage & Letters: Producing custom signs with clean edges and precise shapes for your laser cut letters.

3. Model Making: Crafting detailed architectural models and prototypes.

4. Decorative Items: Creating ornamental pieces and personalized gifts.

Any Ideas about Laser Cutting MDF, Welcome to Discuss with Us!

There are different laser sources like CO2 Laser, diode laser, fiber laser, that are suitable for various materials and applications. Which one is suitable for cutting MDF(and engraving MDF)? Let's dive into.

1. CO2 Laser:

Suitable for MDF: Yes

Details: CO2 lasers are the most commonly used for cutting MDF due to their high power and efficiency. They can cut through MDF smoothly and precisely, making them ideal for detailed designs and projects.

2. Diode Laser:

Suitable for MDF: Limited

Details: Diode lasers can cut through some thin MDF sheets but are generally less powerful and efficient compared to CO2 lasers. They are better suited for engraving rather than cutting thick MDF.

3. Fiber Laser:

Suitable for MDF: No

Details: Fiber lasers are typically used for metal cutting and are not suitable for cutting MDF. Their wavelength is not well absorbed by non-metal materials like MDF.

4. Nd:YAG Laser:

Suitable for MDF: No

Details: Nd:YAG lasers are also primarily used for metal cutting and welding, making them unsuitable for cutting MDF boards.

CO2 Laser is the most suitable laser source for cutting MDF board, next, we are gonna introduce a few of popular and common CO2 Laser Cutting Machine for MDF board.

Some Factors You Should Consider

About the MDF cutting laser machine, there are some factors you should consider when selecting:

1. Machine Size(working format):

The factor determines how size of the patterns and MDF board you are gonna use a laser to cut. If you buy mdf laser cutting machine for making small decoration, crafts or artwork for hobby, the working area of 1300mm * 900mm is suitable for you. If you are engaged in processing large signage or furniture, you should choose a large format laser cutting machine such as with a 1300mm * 2500mm working area.

2. Laser Tube Power:

How much of the laser power determines how powerful the laser beam is, and how thick of MDF board you can use the laser to cut. Generally speaking, 150W laser tube is the most common and can meet most MDF board cutting. But if your MDF board is thicker up to 20mm, you should choose 300W or even 450W. If you are gonna cut thicker more than 30mm, the laser is not suitable for you. You should choose the CNC router.

Related Laser Knowledge: How to extend the service life of laser tube >

3. Laser Cutting Table:

For cutting wood like plywood, MDF, or solid wood, we suggest using the knife strip laser cutting table. The laser cutting table consists of multiple aluminum blades, that can support the flat material and maintain minimal contact between laser cutting table and material. That is ideal to produce a clean surface and cut edge. If your MDF board is so thick, you can also consider using the pin working table.

4. Cutting Efficiency:

Evaluate your productivity such as the daily yield you want to reach, and discuss it with an experienced laser expert. Usually, the laser expert will recommend multiple laser heads or higher machine power to help you with the expected yield. Besides, there are other laser machine configurations like servo motors, gear and rack transmission devices, and others, that all have an impact on the cutting efficiency. So it's wise to consult your laser supplier and find optimal laser configurations.

Have no idea of how to choose laser machine? Talk with our laser expert!

Popular MDF Laser Cutting Machine

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2000mm/s

• Mechanical Control System: Step Motor Belt Control

• Working Area: 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 150W/300W/450W

• Max Cutting Speed: 600mm/s

• Position Accuracy: ≤±0.05mm

• Mechanical Control System: Ball Screw & Servo Motor Drive

Learn more about the laser cutting MDF or other wood

Related News

Pine, Laminated Wood, Beech, Cherry, Coniferous Wood, Mahogany, Multiplex, Natural Wood, Oak, Obeche, Teak, Walnut and more.

Almost all wood can be laser cut and the laser cutting wood effect is excellent.

But if your wood to be cut adhered to toxic film or paint, safety precaution is necessary while laser cutting.

If you are not sure, inquire with a laser expert is the best.

When it comes to acrylic cutting and engraving, CNC routers and lasers are often compared.

Which one is better?

The truth is, they are different but complement each other by playing unique roles in different fields.

What are these differences? And how should you choose? Get through the article and tell us your answer.

Laser Cutting, as a subdivision of applications, has been developed and stands out in cutting and engraving fields. With excellent laser features, outstanding cutting performance, and automatic processing, laser cutting machines are replacing some traditional cutting tools. CO2 Laser is an increasingly popular processing method. The wavelength of 10.6μm is compatible with almost all non-metal materials and laminated metal. From daily fabric and leather, to industrial-used plastic, glass, and insulation, as well as craft materials like wood and acrylic, the laser cutting machine is capable of handling these and realizing excellent cutting effects.

Any Questions about Laser Cut MDF?

Post time: Aug-01-2024