Can You Laser Cut Plywood?

laser cutting machine for Plywood

Plywood is one of the common woods used in furniture, signs, decorations, ships, models, etc. The plywood consists of multiple veneers and is characterized by its lightweight and stability. Plywood is widely used and has great performance, but you may be confused with the laser cut plywood, due to its glues between the veneers of the plywood. Can plywood be laser cut?

In general, the laser can cut plywood and the cutting effect is clean and crisp, but you need to select the right laser types and appropriate laser parameters like power, speed, and air assist. And one thing you need to note is about the plywood types. In this article, we will introduce suitable laser cut plywood machines, how to select plywood, and how to laser cut plywood to get the best cutting effect. In addition, laser engraving plywood is popular for creating unique text, patterns, and logos for plywood products like name tags, gifts, and brand signage.

Follow us to explore the fascinating laser cut plywood projects. If you are interested in one of the plywood laser cutting machines, discuss your preferences and requirements with us.

Can You Laser Cut Plywood?

Absolutely, laser cutting plywood is a popular and efficient method for crafting precise and intricate designs.

With the right laser cutter and suitable plywood, you can achieve clean edges and detailed cuts, making it a preferred choice for various plywood projects and designs.

How to select the Plywood for Laser Cutting & Engraving?

Now we know that plywood is suitable for laser cutting, but the different plywood would produce different cutting effects, so there are some factors you need to consider when selecting plywood for laser:

1. Plywood Resin:

The resin content in plywood has an impact on the cutting and engraving effect. Higher resin content, means darker marks left on the wood edge or surface. So unless you have rich experience in debugging laser machines and setting laser parameters, we don't recommend choosing plywood with a high resin content.

2. Plywood Surface:

When selecting plywood, consider its shade, grain, and color. Laser cutting and engraving can leave dark marks, so choose a plywood finish that matches your product requirements and style. For instance, if you plan to laser engrave text or greetings, ensure the grain won't interfere with the engraving marks and patterns.

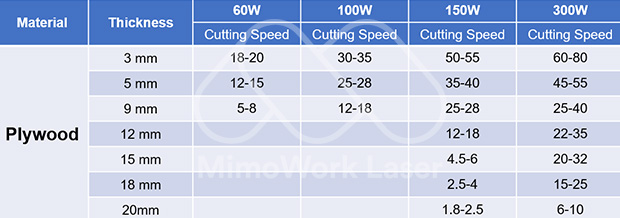

3. Plywood Thickness:

Generally speaking, to ensure the cutting quality, we recommend that the maximum wood thickness that the laser can cut is within 20mm. Different thicknesses of plywood, require different laser powers. When you purchase the plywood laser cutting machine, consult your laser supplier for optimal laser tube power and cutting power.

4. Plywood Types:

There are some common plywood types suitable for laser you can refer to: bamboo plywood, brich plywood, hoop pine plywood, basswood plywood, and beech plywood.

What is Laser Cutting Plywood?

The laser focuses intense heat energy onto a small area of the plywood, heating it to the point of sublimation. So there is little debris and fragments left. The cutting surface and surrounding area are clean.

Due to the strong power, the plywood will be directly cut through where the laser passes.

Suitable Laser Types for Cutting Plywood

CO2 Laser and Diode Laser are the two main laser types for processing plywood.

1. CO2 laser is versatile and powerful that it can fast cut through thick plywood, leaving a crisp and smooth cutting edge. And for laser engraving plywood, CO2 laser enable customized patterns, shapes and logos. So if you are invest a laser machine for plywood production, fast cutting and engraving, the CO2 laser machine is suitable.

2. Diode laser is less powerful for cutting plywood due to its lower power. But it's suitable for engraving and marking on the plywood surface. Customized and flexible.

Laser cutting plywood is fast, especially for the CO2 laser. With high automation like auto-focus, auto-lifting laser cutting table, digital laser cutting software, and more, the plywood laser cutting process is with less labor and higher cutting quality.

Laser cutting plywood involves using a high-powered laser to precisely cut through the material. The laser beam is directed at the plywood, sublimating the material along the cut line and producing a smooth edge.

Laser is versatile for cutting and engraving customized designs like Christmas ornaments, gift tags, crafts, and models.

We have used a piece of plywood to make some Laser Cut Christmas ornaments, it is beautiful and intricate. Interested in that, check the video out.

◆ Flexibility

Lasers can cut a wide range of shapes and patterns, allowing for creative and intricate designs.

◆ High Precision

Laser cutters can achieve incredibly detailed and accurate cuts on plywood. You can design and create complex and intricate designs like hollow patterns, the laser cutter will make it due to its super thin laser beams.

◆ Smooth Edge

The laser beam produces clean and smooth edges without the need for additional finishing.

◆ High Efficient

Laser cutting is typically faster than traditional cutting methods, increasing productivity.

◆ No Physical Wear

Unlike saw blades, the laser does not physically contact the plywood, meaning there is no wear and tear on the cutting tool.

◆ Max Material Utilization

The precision of laser cutting reduces material waste, making it more economical.

1. Architectural Models: Precise laser beam and flexible laser cutting bring intricate and detailed laser cut plywood models, for architectural models and prototypes.

2. Signage: The plywood laser cutting machine is powerful that it can cut through thick plywood while being with clean and smooth cut edge. Laser cut plywood signage is convenient for creating custom signs with intricate designs and lettering.

3. Furniture: Laser cut plywood furniture brings more design flexibility for furniture designer and hobbyist. With the high precision, laser cutting plywood can create exquisite living hinge (also called flexible wood), enhancing appearance and uniqueness for furniture and artwork.

4. Ornaments & Crafts: Producing decorative items such as wall art, ornaments, and home décor.

Besides that, laser cutting plywood is popular among laser cutting flexible wood, laser cutting wood puzzle, laser cutting wood lightbox, laser cutting artwork.

Get a laser cutter, free your creativity, make your plywood products!

Any Ideas about Laser Cutting plywood, Welcome to Discuss with Us!

CO2 Laser is the most suitable laser source for cutting plywood boards, next, we are gonna introduce a few popular and common CO2 Laser Cutting Machine for plywood.

Some Factors You Should Consider

When choosing a laser cutting machine for plywood, several factors should be considered to ensure you get the best results for your projects:

1. Machine Size(working format):

The machine size determines the maximum size of the plywood sheets and patterns you can cut. If you are creating small decorations, crafts, or artwork for hobbies, a working area of 1300mm * 900mm is suitable. For larger projects such as signage or furniture, a large format laser cutting machine with a working area of 1300mm * 2500mm is ideal.

2. Laser Tube Power:

The power of the laser tube determines the strength of the laser beam and the thickness of the plywood you can cut. A 150W laser tube is common and meets most plywood cutting needs. For thicker plywood up to 20mm, you may need a 300W or even a 450W laser tube. If you need to cut plywood thicker than 30mm, a CNC router might be more suitable than a laser cutter.

Related Laser Knowledge: How to extend the service life of laser tube >

3. Laser Cutting Table:

For cutting wood materials like plywood, MDF, or solid wood, a knife strip laser cutting table is recommended. This table consists of multiple aluminum blades that support the material while maintaining minimal contact, ensuring a clean surface and cut edge. For thicker plywood, you might also consider using a pin working table. More information about laser cutting table >

4. Cutting Efficiency:

Evaluate your plywood productivity needs, such as the daily yield you want to achieve, and discuss them with an experienced laser expert. We have designed multiple laser heads or higher machine power to meet your production goals. Some innovations in laser cutting tables, like auto-lifting laser cutting table, exchange table, and rotary devices, can greatly improve plywood cutting and engraving. Additionally, other configurations like servo motors and gear and rack transmission devices can impact cutting efficiency. Consulting with your laser supplier will help you find the optimal laser configurations for your needs.

Have no idea of how to choose laser machine? Talk with our laser expert!

Popular Plywood Laser Cutting Machine

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2000mm/s

• Mechanical Control System: Step Motor Belt Control

• Working Area: 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 150W/300W/450W

• Max Cutting Speed: 600mm/s

• Position Accuracy: ≤±0.05mm

• Mechanical Control System: Ball Screw & Servo Motor Drive

FAQ of Laser Cutting Plywood

1. What thickness plywood can a laser cut?

We know CO2 laser is the most suitable laser type for cutting plywood. The max cutting thickness we suggest is 20mm, which can satisfy great cutting effect and cutting speed. We have test different thicknesses of wood for laser cutting and made a video to display. Check this out.

2. How to find the right focus for laser cutting plywood?

For adjusting the focus length for laser cutting, MimoWork designed the auto-focus device and auto-lifting laser cutting table, to assist you find the optimal focus length for materials to be cut.

Besides, we made a video tutorial to step by step instruct how to determine the focus. Check this out.

3. How much power does a laser need to cut plywood?

How much of laser power you need depends on the thickness of the plywood you are gonna cut. 150W is a common laser power for cutting most plywood from 3mm thickness to 20mm thickness. You just need to adjust the percentage of power on a piece of scrap, to find the optimal cutting parameters.

We suggest running the laser machine at no more than 80%-90% of the max laser power, to prolong the life-span of the laser tube.

Learn more about the laser cutting plywood or other wood

Related News

Pine, Laminated Wood, Beech, Cherry, Coniferous Wood, Mahogany, Multiplex, Natural Wood, Oak, Obeche, Teak, Walnut and more.

Almost all wood can be laser cut and the laser cutting wood effect is excellent.

But if your wood to be cut adhered to toxic film or paint, safety precaution is necessary while laser cutting.

If you are not sure, inquire with a laser expert is the best.

When it comes to acrylic cutting and engraving, CNC routers and lasers are often compared.

Which one is better?

The truth is, they are different but complement each other by playing unique roles in different fields.

What are these differences? And how should you choose? Get through the article and tell us your answer.

Have you been trying to find a way to create a custom puzzle? When extremely high accuracy and precision are required, laser cutters are almost always the best choice.

This is the process of cutting material with the laser beam, as the name suggests. This can be done to trim down a material or to assist in cutting it into intricate forms that would be difficult for more traditional drills to handle. Aside from cutting, laser cutters may also raster or etch designs onto workpieces by heating the workpiece's surface and drilling off the top layer of the material to modify the appearance where the raster operation was completed.

Any Questions about Laser Cut Plywood?

Post time: Aug-08-2024