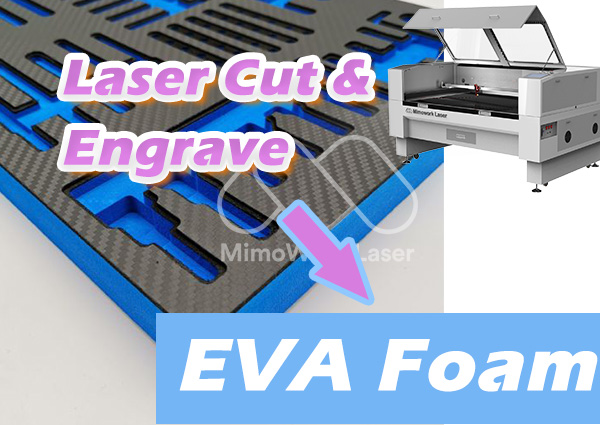

Can you laser cut EVA foam?

Table of Content:

What is EVA Foam?

EVA foam, also known as Ethylene-Vinyl Acetate foam, is a type of synthetic material that is popularly used for a wide range of applications. It is made by combining ethylene and vinyl acetate under heat and pressure, resulting in a durable, lightweight, and flexible foam material. EVA foam is known for its cushioning and shock-absorbing properties, making it a popular choice for sports equipment, footwear, and crafts.

Laser Cut Eva Foam Settings

Laser cutting is a popular method for shaping and cutting EVA foam due to its precision and versatility. The optimal laser cutting settings for EVA foam can vary depending on the specific laser cutter, its power, the thickness and density of the foam, and the desired cutting results. It's important to perform test cuts and adjust the settings accordingly. However, here are some general guidelines to get you started:

▶ Power

Start with a lower power setting, around 30-50%, and gradually increase it if needed. Thicker and denser EVA foam may require higher power settings, while thinner foam may require lower power to avoid excessive melting or charring.

▶ Speed

Begin with a moderate cutting speed, typically around 10-30 mm/s. Again, you may need to adjust this based on the thickness and density of the foam. Slower speeds can result in cleaner cuts, while faster speeds may be suitable for thinner foam.

▶ Focus

Ensure the laser is properly focused on the surface of the EVA foam. This will help achieve better cutting results. Follow the instructions provided by the laser cutter manufacturer on how to adjust the focal length.

▶ Test Cuts

Before cutting your final design, perform test cuts on a small sample piece of EVA foam. Use different power and speed settings to find the optimal combination that provides clean, precise cuts without excessive burning or melting.

Video | How to Laser Cut Foam

Laser Cut Foam Cushion for Car Seat!

How Thick can Laser Cut Foam?

Any questions about how to laser cut eva foam

Recommended Laser Cutting Machine for EVA foam

Is it Safe to Laser-Cut EVA Foam?

When the laser beam interacts with the EVA foam, it heats and vaporizes the material, releasing gases and particulate matter. The fumes generated from laser cutting EVA foam typically consist of volatile organic compounds (VOCs) and potentially small particles or debris. These fumes can have an odor and may contain substances such as acetic acid, formaldehyde, and other combustion byproducts.

It is important to have proper ventilation in place when laser cutting EVA foam to remove the fumes from the working area. Adequate ventilation helps maintain a safe working environment by preventing the accumulation of potentially harmful gases and minimizing the odor associated with the process.

Is There Any Material Request?

The most common type of foam used for laser cutting is polyurethane foam (PU foam). PU foam is safe to laser cut because it produces minimal fumes and does not release toxic chemicals when exposed to the laser beam. Besides PU foam, foams made from polyester (PES) and polyethylene (PE) are also ideal for laser cutting, engraving, and marking.

However, certain PVC-based foam could generate toxic gases when you laser. A fume extractor can be a good option to consider if you need to laser-cut such foams.

Cut Foam: Laser VS. CNC VS. Die Cutter

The choice of the best tool largely depends on the thickness of the EVA foam, the complexity of the cuts, and the level of precision required. Utility knives, scissors, hot wire foam cutters, CO2 laser cutters, or CNC routers can all be good options when it comes to cutting EVA foam.

A sharp utility knife and scissors can be great choices if you only need to perform straight or simple curved edges, also it’s relatively cost-effective. However, only thin EVA foam sheets can be cut or curved manually.

If You are in Business, Automation, and Precision Shall be your Priority to Consider.

In such case, a CO2 laser cutter, CNC router, and Die Cutting Machine shall be considered.

▶ CNC Router

If you have access to a CNC (Computer Numerical Control) router with a suitable cutting tool (such as a rotary tool or knife), it can be used for cutting EVA foam. CNC routers offer precision and can handle thicker foam sheets.

▶ Die Cutting Machine

A laser cutter, such as a desktop CO2 laser or a fiber laser, is a precise and efficient option for cutting EVA foam, especially for complex or intricate designs. Laser cutters provide clean, sealed edges and are often used for larger-scale projects.

The Advantage of Laser Cutting Foam

When cutting industrial foam, the advantages of laser cutter over other cutting tools are obvious. It can create the finest contours due to precise and non-contact cutting, with the most clean and flat edge.

When using water jet cutting, water will be sucked into the absorbent foam during the separation process. Before further processing, the material must be dried, which is a time-consuming process. Laser cutting omits this process and you can continue processing the material immediately. In contrast, the laser is very convincing and is clearly the number one tool for foam processing.

Conclusion

MimoWork’s laser cutting machines for EVA foam are equipped with built-in fume extraction systems that help capture and remove the fumes directly from the cutting area. Alternatively, additional ventilation systems, such as fans or air purifiers, can be used to ensure the removal of fumes during the cutting process.

Common Materials of laser cutting

Post time: May-18-2023