Why Dry Ice Blasting is Propelling Money

Laser Cleaning Machine Price Now [2024-12-17]

Compared to 2017's Price of 10,000$

Before you even ask, no, this is NOT a scam.

Starting From 3,000 US Dollar ($)

Want to get your very own Laser Cleaning Machine now? Contact us!

Dry ice blasting has been a popular cleaning method in various industries, but it comes with significant drawbacks that can make it an expensive choice.

Here’s a closer look at why dry ice blasting may not be the best investment compared to alternatives like laser cleaning.

Table of Content:

1. Application Similarity: Between Dry Ice & Laser

Both from Handheld Version of their Counterparts

Both dry ice blasting and laser cleaning can be utilized in handheld applications, making them versatile for cleaning tasks in various settings.

However, while both methods aim to remove contaminants from surfaces, their effectiveness and efficiency differ significantly.

Laser cleaning offers precise control and can effectively clean a wider range of contaminants without the need for consumables.

Unlike dry ice blasting, which relies on the continuous supply of dry ice pellets.

Both dry ice blasting and laser cleaning are versatile methods used in various industries for surface cleaning and restoration.

List of Applications (Applicable for Both Dry Ice Blasting & Laser Cleaning):

Restoration of Historical Artifacts

Manufacturing Equipment Maintenance

Electrical Components

Precision Cleaning in Aerospace

Medical Equipment Sterilization

Art Restoration

Industrial Equipment Maintenance

With the Advancement of Modern Technology

Laser Cleaning Machine Price has Never been this Affordable!

2. High Consumable Costs of Dry Ice Blasting

From Dry Ice Pellets Shortages to Energy Consumption

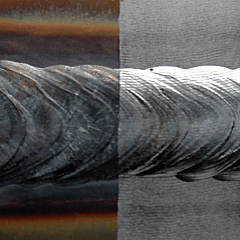

Dry Ice Blasting on Rusted Bolts

One of the most significant drawbacks of dry ice blasting is its high consumable costs.

The expenses associated with dry ice blasting include:

Cost of Dry Ice Pellets

Dry ice is not only expensive to purchase but also requires careful handling and storage to prevent sublimation.

This adds to the overall operational costs.

Energy Consumption

The process is energy-intensive, particularly due to the need for compressed air, which can lead to high electricity bills.

Air compressors are among the highest recurring expenses in factories.

Dry Ice Shortages

The availability of dry ice can be inconsistent, as seen during shortages caused by supply chain disruptions.

For instance, in 2022, both Europe and the US faced dry ice shortages due to rising natural gas prices and CO2 supply issues.

Choosing Between Pulsed & Continuous Wave (CW) Laser Cleaners?

We Can Help Make the Right Decision Based on Applications

3. Dry Ice Blasting Isn't So Green & Safe

Environmentally Friendly? Not Really...

True Green Cleaning: Laser Cleaning

Dry Ice Blasting Isn't So Green

While dry ice blasting is often marketed as an environmentally friendly option, the reality is more complex.

The production of dry ice pellets involves processes that are not particularly green.

As they are derived from CO2 generated during the refining of fossil fuels and chemicals.

This means that while the cleaning process itself may not add CO2 to the atmosphere.

The production of dry ice does contribute to greenhouse gas emissions.

Dry Ice Blasting Isn't So Safe

Safety is another critical concern with dry ice blasting. The process poses several risks:

Cold Temperatures:

Handling dry ice can lead to frostbite or cold burns, necessitating the use of insulated gloves and protective gear.

Air Quality Risks:

As dry ice sublimates, it releases CO2 gas, which can accumulate in poorly ventilated areas, posing asphyxiation risks to workers.

Proper ventilation systems are essential to mitigate this danger.

Choosing Between Pulsed & Continuous Wave (CW) Laser Cleaners?

We Can Help Make the Right Decision Based on Applications

4. Why Laser Cleaning is Better

Laser Cleaning Presents Several Advantages over Dry Ice Blasting

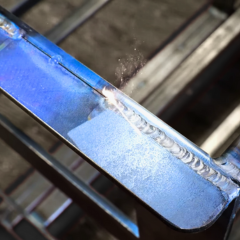

Laser Cleaning Aluminum

Lower Operating Costs

Laser cleaning does not require consumables, which significantly reduces ongoing costs.

Once the initial investment in equipment is made, the operational expenses are much lower compared to the recurring costs of dry ice.

Environmental Impact

Laser cleaning is more and truly environmentally friendly.

As it does not produce secondary waste or require the use of consumables that contribute to carbon emissions.

Safety & Effectiveness

Laser cleaning is generally safer, requiring less protective gear and generating minimal noise.

The risk of cold burns and asphyxiation is significantly lower compared to dry ice blasting.

Laser cleaning can achieve a higher level of cleanliness and precision, making it suitable for a broader range of applications.

Including sensitive surfaces that may be damaged by abrasive methods like dry ice blasting.

Do you Know Laser Cleaner are Also called Laser Paint Stripper?

If the answer is no.

Well, at least we do!

Check out this article written by us about Paint Stripping Laser.

From metal to wood, with the right settings, it does wonders.

Industrial Laser Cleaner: Editor’s Pick for Every Needs

Want to find the perfect laser cleaning machine for your needs & business?

This article listed some of our best recommendations for laser cleaning needs.

From Continuous Wave to Pulsed Type Laser Cleaners.

Laser Cleaning at its Finest

The pulsed fiber laser featuring high precision and no heat affection area usually can reach an excellent cleaning effect even if under a low power supply.

Due to the noncontinuous laser output and high peak laser power,

This pulsed laser cleaner is more energy-saving and suitable for fine parts cleaning.

The fiber laser source has premium stability and reliability, with the adjustable pulsed laser, is flexible and serviceable in rust removal, paint removal, stripping coating, and eliminating oxide and other contaminants.

"Beast" High-Power Laser Cleaning

Different from pulse laser cleaner, the continuous wave laser cleaning machine can reach higher-power output which means higher speed and larger cleaning covering space.

That’s an ideal tool in shipbuilding, aerospace, automotive, mold, and pipeline fields due to the highly efficient and steady cleaning effect regardless of the indoor or outdoor environment.

The high repetition of the laser cleaning effect and lower maintenance cost make the CW laser cleaner machine a favorable and cost-effective cleaning tool, helping your production upgrade for higher benefits.

Things You NEED to Know about: Pulsed Laser Cleaner

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Dec-19-2024