Industrial vs. Home Fabric Cutting Machines: What's the Difference?

Industrial vs. Home Fabric Cutting Machines

Fabric cutting machines are an essential tool for the textile industry and home sewists alike. However, there are significant differences between industrial and home laser fabric cutter. In this article, we will explore the differences between these two types of machines, including their features, capabilities, and costs.

Capacity

One of the most significant differences between industrial and home fabric cutting machines is their capacity. Industrial fabric laser cutters are designed to handle large volumes of fabric quickly and efficiently. These machines can cut through multiple layers of fabric at once, making them ideal for mass production. Home fabric cutting machines, on the other hand, have a much lower capacity and are designed for personal use or small-scale production.

Speed

Industrial Fabric cutter laser are built for speed. They can cut through fabric at a rate of several hundred feet per minute, making them ideal for high-volume production. Home fabric cutting machines are typically slower and may require multiple passes to cut through thicker fabrics.

Accuracy

Industrial fabric cutting machines are designed for precision and accuracy. They are built with advanced cutting mechanisms that ensure clean and precise cuts every time. Home fabric cutting machines may not be as precise as their industrial counterparts, especially when cutting through thicker or more complex fabrics.

Durability

Industrial fabric laser cutters are built to last. They are designed to withstand heavy use and can operate continuously for hours without overheating or breaking down. Home fabric cutting machines may not be as durable, and their lifespan may be shorter due to the lower quality of materials and construction.

Size

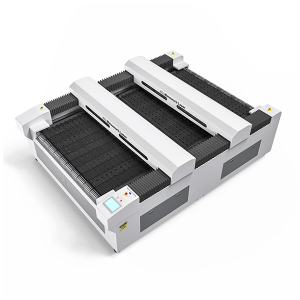

Industrial fabric cutting machines are larger and heavier than home fabric cutting machines. They require a significant amount of space and are typically installed in a dedicated cutting room or area. Home fabric cutting machines are smaller and more portable, making them ideal for home use or small studios.

Cost

Industrial fabric cutting machines are much more expensive than home fabric laser cutting. They can cost anywhere from several thousand to tens of thousands of dollars, depending on the features and capabilities of the machine. Home fabric cutting machines are generally much more affordable and can be purchased for a few hundred to a few thousand dollars.

Features

Industrial fabric cutting machines come equipped with advanced features such as computerized controls, automatic sharpening systems, and advanced safety mechanisms. Home fabric cutting machines may not have as many features, but they can still be effective for personal use or small-scale production.

Maintenance

Industrial laser fabric cutter require regular maintenance to keep them operating at peak performance. They may require professional maintenance or repairs, which can be costly. Home fabric cutting machines are generally easier to maintain and may only require routine cleaning and blade sharpening.

In Conclusion

Industrial fabric cutting machines and home fabric cutting machines are designed for different purposes and have significant differences in terms of capacity, speed, accuracy, durability, size, cost, features, and maintenance. Industrial machines are ideal for high-volume production, while home machines are more suitable for personal use or small-scale production. When choosing a fabric cutting machine, it is essential to consider your specific needs and budget to find the machine that is right for you.

Video Display | Glance for Cordura Laser Cutting

Recommended Fabric laser cutter

Any questions about the operation of Fabric Laser Cutter?

Post time: Apr-10-2023