Denim Laser Design from Water-free Technic

Classic Denim Fashion

Denim is always the dispensible fashion in everyone's wardrobe. Except for the draping and accessories decoration, the unique appearance from washing and finishing technics also fresh the denim fabrics. This article will show a new denim finishing technic - denim laser engraving. To provide advanced technical support and improve market competition for denim and jeans apparel manufacturers, laser denim finishing technology including laser engraving and laser marking digs out more potentials of denim (jeans) to make varieties of styles and more flexible processing come true.

Contents Overview ☟

• Introduction of denim wash technics

• Why choose laser denim finishing

• Denim applications of laser finishing

• Denim laser design and machine recommendation

Introduction of denim washes technics

You may be familiar with traditional washing and finishing denim technologies, like the stone wash, mill wash, moon wash, bleach, distressed look, monkey wash, cat whiskers effect, snow wash, holing, tinting, 3D effect, PP spray, sandblast. Putting to use chemical and mechanical treatment on the denim fabric is unavoidable to result in negative environmental effects and fabric damage. Among that, immense water consumption may be the first headache for denim and garment manufacturers. Especially for the constant concern about the environment, the government and some enterprises gradually take responsibility for ecological protection. Also, the preferred choice for eco-friendly products from customers prompt technical innovation on fabric & clothing design and production.

For instance, Levi’s has realized the zero chemicals emission in denim production with the help of laser on denim by 2020 and digitalized the production line for less labor and energy input. Research shows that the new laser technology can save energy by 62%, water by 67%, and chemical products by 85%. That's a huge improvement for production efficiency and environmental protection.

Why choose denim laser engraving

Speaking of laser technology, laser cutting has occupied a part of the textile market whether for mass production, or small-batch customization. Automatic and customized laser characteristics make the sign obvious to replace traditional manual or mechanical processing with laser cutting. But not only that, unique thermal treatment from denim laser engraving machine can burn part materials to a depth by adjusting proper laser parameters, forming amazing & permanent image, logo, and text on the fabrics. That brings another renovation for denim fabric finishing and washing. The powerful laser beam can be digitally controlled to engrave surface materials, revealing the inner fabric color and texture. You will get the amazing color fading effect in different shades without the need for any chemical treatment. Sense of depth and stereo perception is self-evident. Learn more about denim laser engraving and marking!

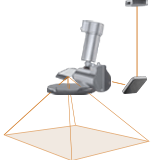

Galvo Laser Engraving

Besides denim discoloration, denim laser distressing can build up a distressing and worn effect. The fine laser beam can be precisely positioned on the right area and starts quick denim laser engraving and jeans laser marking in response to the uploaded graphic file. The popular whisker effect and ripped distressed look can all be realized by the denim laser marking machine. Vintage effect lines with the trend fashion. For hand-made enthusiasts, DIY your design on jeans, denim coats, hats, and others is a good idea to show personality.

Advantages of laser denim finishing:

◆ Flexible and customized:

Alert laser can accomplish any pattern marking and engraving as the input design file. No limit on the pattern positions and sizes.

◆ Convenient and efficient:

Once forming gets rid of pre & post-processing and labor finishing. Coordinating with the conveyor system, auto-feeding & laser engraving on denim without manual intervention becomes possible.

◆ Automatic and cost-saving:

A denim jeans laser engraving machine invested can eliminate tedious processes from traditional technologies. No requirement of tool and model, eliminate labor effort.

◆ Environment-friendly:

Almost no chemical and water consumption, denim laser print and engraving rely on the energy from the photoelectric response and is a clean energy source.

◆ Safe and no contamination:

Whether for destroy wash or discoloration, laser finishing can produce varied vision according to denim itself. Mathematic CNC system and ergonomics machine design ensure the operation safety.

◆ Wide range of applications:

Due to no limit on the model, any denim products for any size and shape can be laser treated. Customized design and mass production from the laser jeans design machine are accessible.

Denim laser design and machine recommendation

Video Display

Denim laser marking by Galvo Laser Marker

✦ Ultra-speed and fine laser marking

✦ Auto-feeding and marking with conveyor system

✦ Upgraded extensile working table for different material formats

Laser cut denim fabric

Flexible laser cutting patterns and shapes provide more design styles for fashion, clothing, apparel accessories, outdoor equipment.

How to laser cut the denim fabric?

• design the pattern and import the graphic file

• set the laser parameter (details to inquire us)

• upload the denim roll fabric on the auto-feeder

• start the laser machine, auto feeding and conveying

• laser cutting

• collecting

Denim Laser Machine

Any questions about denim laser engraving?

(jeans laser engraving machine price, denim laser design ideas)

Who are we:

Mimowork is a results-oriented corporation bringing 20-year deep operational expertise to offer laser processing and production solutions to SMEs (small and medium-sized enterprises) in and around clothing, auto, ad space.

Our rich experience of laser solutions deeply rooted in the advertisement, automotive & aviation, fashion & apparel, digital printing, and filter cloth industry allows us to accelerate your business from strategy to day-to-day execution.

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator. Please contact us: Linkedin Homepage and Facebook homepage or info@mimowork.com

Post time: Feb-01-2022