Design Tips for Fabric Laser Cutting

A guide of Laser cutting for fabrics

Fabric laser cutting is a versatile and precise method of cutting a wide range of materials, including textiles, leather, and more. It offers designers the opportunity to create intricate and complex designs that would be difficult or impossible to achieve through traditional cutting methods. However, to ensure the best results, it's important to consider certain design factors when creating a design for laser fabric cutter. In this article, we'll explore some design tips for fabric laser cutting.

Vector-Based Designs

One of the most important factors to consider when designing for laser fabric cutter is the use of vector-based designs. Vector-based designs are made up of mathematical equations and are created using design software such as Adobe Illustrator. Unlike raster-based designs, which are made up of pixels, vector-based designs can be scaled up or down without losing quality, making them ideal for fabric laser cutting.

Minimal Design

Another important factor to consider is the use of a minimal design. Because laser fabric cutter can produce intricate and complex designs, it's easy to go overboard with the number of elements in a design. However, a simple and clean design is often the most effective when it comes to Fabric laser cutter. This is because a minimal design allows the laser to cut more precisely and quickly, resulting in a higher-quality finished product.

Consider Material Thickness

It's also important to consider the thickness of the material you'll be cutting when designing for fabric laser cutting. Depending on the material, the laser may have difficulty cutting through thicker layers. In addition, thicker materials may take longer to cut, resulting in higher production costs. By considering the thickness of the material when designing, you can create a design that is optimized for the specific material you'll be cutting.

Simplify Text

When designing text for Fabric laser cutter, it's important to simplify the font and avoid using overly complex fonts or designs. This is because the laser may have difficulty cutting through fine details in the text. Instead, consider using simple fonts with thicker lines and fewer details.

Test Designs

Finally, it's important to test designs before moving forward with production. This can be done by creating a small sample of the design and running it through the fabric laser cutter. This allows you to see how the design will look when cut and make any necessary adjustments before moving forward with a larger production run.

In Conclusion

designing for fabric laser cutting requires careful consideration of factors such as vector-based designs, minimalism, material thickness, simplifying text, and testing designs. By taking these factors into account when designing, you can create designs that are optimized for fabric laser cutting and result in a high-quality finished product. Whether you're creating custom clothing, accessories, or other textile products, fabric laser cutting offers endless possibilities for creative expression.

Video Display | Glance for Laser Fabric Cutter

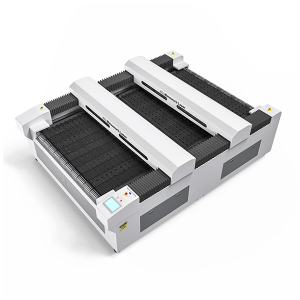

Recommended Fabric laser cutter

Any questions about the operation of Fabric Laser Cutter?

Post time: Apr-04-2023