Endless Possibilities of Laser-Cut Wood Crafts

Introduction

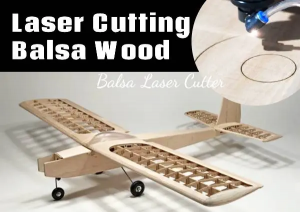

Wood, a natural and eco-friendly material, has long been used in construction, furniture, and crafts. However, traditional methods struggle to meet modern demands for precision, customization, and efficiency. The introduction of laser cutting technology has transformed wood processing. This report highlights the value of wood laser cutting and its impact on craftsmanship.

Laser cut wood enables intricate designs, while a wood laser cutting machine maximizes material use and reduces waste. Laser cutting wood is also sustainable, minimizing waste and energy use. By adopting wood laser cutting, industries achieve precision, customization, and eco-friendly production, redefining traditional woodworking.

The Uniqueness of Wood Laser Cutting

Wood laser cutting technology enhances the efficiency of traditional craftsmanship through modernization while achieving material savings, personalized customization, and green sustainability, demonstrating its unique value in foreign trade promotion and manufacturing.

Saving Materials

Laser cutting minimizes material waste through optimized layout and path planning. Compared to traditional cutting methods, laser cutting achieves higher-density cutting on the same piece of wood, reducing production costs.

Supporting Custom Designs

Laser cutting technology makes small-batch, personalized customization possible. Whether it's intricate patterns, text, or unique shapes, laser cutting can easily achieve them, meeting consumers' demand for personalized products.

Green & Sustainable

Laser cutting requires no chemical agents or coolants and produces minimal waste, aligning with modern manufacturing's demands for environmental friendliness and sustainability.

Innovative Applications of Wood Laser Cutting

▶ The Fusion of Art and Design

Laser cutting provides artists and designers with a new creative tool. Through laser cutting, wood can be transformed into exquisite artworks, sculptures, and decorations, showcasing unique visual effects.

▶ Smart Home and Custom Furniture

Laser cutting technology makes custom furniture production more efficient and precise. For example, it can customize engraved patterns, hollow designs, or functional structures based on customer needs, meeting the personalized demands of smart homes.

▶ Digital Preservation of Cultural Heritage

Laser cutting technology can be used to replicate and restore traditional wooden structures and crafts, providing technical support for the preservation and inheritance of cultural heritage.

Future Development Trends

✓ Intelligence and Automation

In the future, laser cutting equipment will become more intelligent, integrating AI and machine vision technologies to achieve automatic recognition, layout, and cutting, further improving production efficiency.

✓ Multi-Material Composite Processing

Laser cutting technology will not be limited to wood but can also be combined with other materials (such as metal and plastic) to achieve multi-material composite processing, expanding its application fields.

✓ Green Manufacturing

With increasing environmental awareness, laser cutting technology will develop in a more energy-efficient and eco-friendly direction, reducing energy consumption and carbon emissions.

What are the Laser Engraved Wooden Crafts?

Wooden Laser Engraving Crafts

| Wooden Bookmark |

| Wooden Home Ornaments |

| Wooden Coaster |

| Wooden Clock |

| Wooden Puzzle |

| Wooden Music Box |

| Wooden 3D Letters |

| Wooden Keychain |

Engraved Wood Ideas

Best Way to Start a Laser Engraving Business

How to make a wood laser engraving design? The video shows the making process of Iron Man woodcraft. As a laser engraver tutorial, you can get the operation steps and wood engraving effect. The wood laser engraver has an excellent engraving and cutting performance and is your best investment choice with the small laser size and flexible processing. Easy operation and real-time observation of wood engraving are friendly for beginners to realize your laser engraving ideas.

Common Problems and Solutions in Wood Laser Cutting

Burnt Edges

Problem: Edges appear blackened or burnt. Solution: Reduce laser power or increase cutting speed. Use compressed air to cool the cutting area. Choose wood with low resin content.Wood Cracking

Problem: Wood cracks or warps after cutting. Solution: Use dry and stable-quality wood. Reduce laser power to minimize heat buildup. Pre-treat the wood before cutting.

Incomplete Cutting

Problem: Some areas are not fully cut. Solution: Check and adjust the laser focal length. Increase laser power or perform multiple cuts. Ensure the wood surface is flat.Resin Leakage

Problem: Resin leaks during cutting, affecting quality. Solution: Avoid high-resin woods like pine. Dry the wood before cutting. Regularly clean the equipment to prevent resin buildup.Any Ideas about Laser Cutting Wood Crafts, Welcome to Discuss with Us!

Recommended Machines

Popular Plywood Laser Cutting Machine

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2000mm/s

• Mechanical Control System: Step Motor Belt Control

• Working Area: 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 150W/300W/450W

• Max Cutting Speed: 600mm/s

• Position Accuracy: ≤±0.05mm

• Mechanical Control System: Ball Screw & Servo Motor Drive

Have No Idea of How to Choose Laser Machine? Talk with our Laser Expert!

Wood Christmas Decoration

Small Laser Wood Cutter | 2021 Christmas decor

How to make wood Christmas décor or gifts? With the laser wood cutter machine, the design and making are easier and faster.

Only 3 items are required: a graphic file, wood board, and a small laser cutter. Wide flexibility in graphic design and cutting makes you adjust the graphic at any time before wood laser cutting. If you want to make customized business for gifts, and decorations, the automatic laser cutter is a great choice that combines cutting and engraving.

Learn More about Laser Cutting Wood Crafts.

Any Questions About Laser Cutting Wood Crafts?

Post time: Mar-20-2025