Fabric Laser Cutting Machine|The Best of 2023

Do you want to start your business in the clothing and fabric industry from scratch with a CO2 Laser Cutter Machine? In this article, we will elaborate on some key points and make some wholehearted recommendations on some Laser Cutting Machines for Fabric if you want to invest in the Best Fabric Laser Cutting Machine of 2023.

When we say fabric laser cutting machine, we are not simply talking about a laser cutting machine that can cut fabric, we mean the laser cutter that comes with a conveyor belt, auto feeder and all other components to help you cut fabric from roll automatically.

Compared with investing in a regular table-size CO2 laser engraver that’s mainly used for cutting solid materials, such as Acrylic and Wood, you need to choose a textile laser cutter more wisely. In today’s article, we will help you select a fabric laser cutter step by step.

Fabric Laser Cutter Machine

1. Conveyor Tables of a Fabric Laser Cutting Machine

The conveyor table size is the first thing you need to consider if you want to purchase a Laser Fabric Cutter machine. Two parameters you need to pay attention to are the fabric width, and the pattern size.

If you are making a clothing line, 1600 mm*1000 mm and 1800 mm*1000 mm are suitable sizes.

If you are making apparel accessories, 1000 mm*600 mm shall be a good choice.

If you are industrial manufacturers that want to cut Cordura, Nylon, and Kevlar, you should really consider large format fabric laser cutters like 1600 mm*3000 mm and 1800 mm*3000 mm.

We also have our casings factory and engineers, so we also provide customizable machine sizes for Fabric Cutting Laser Machines.

Here is a Table with information about the Suitable Conveyor Table Size according to Different Applications for your Reference.

Suitable Conveyor Table Size Reference Table

2. Laser Power for Laser Cutting Fabric

Once you have determined the size of the machine in terms of material width and design pattern size, you need to start thinking about laser power options. In fact, a lot of cloth needs to use different power, not the market unified think 100w is enough.

All information regarding Laser Power selection for Laser Cutting Fabric are shown in the video

3. Cutting Speed of Laser Fabric Cutting

In short, higher laser power is the easiest option to increase cutting speed. This is especially true if you are cutting solid materials like wood and acrylic.

But for Laser Cutting Fabric, sometimes the power increase may not be able to increase the cutting speed very much. It may cause the fabric fibres to burn and give you a rough edge.

To keep a balance between cutting speed and cutting quality, you can consider multiple laser heads to boost product efficiency in this case. Two heads, four heads, or even eight heads to laser cut fabric at the same time.

In the next video, we will take more about how to improve production efficiency and explain more about multiple laser heads.

Optional Upgrade: Multiple Laser Heads

4. Optional Upgrades for Laser Cutting Fabric Machine

The abovementioned are the three elements to consider when choosing a fabric-cutting machine. We know that many factories have special production requirements, so we provide some options to simplify your production.

A. Visual System

Products like dye sublimation sportswear, printed teardrop flags, and embroidery patches, or your products have patterns on them and need to recognize the contours, we have vision systems to replace the human eyes.

B. Marking System

If you want to mark workpieces to simplify subsequent laser cutting production, such as marking the sewing lines and serial numbers, then you can add Mark Pen or Ink-jet Printer Head on the laser machine.

Most noteworthy is that the Ink-jet Printer use vanishes ink, which can disappear after you heat up your material, and will not affect any aesthetic of your products.

C. Nesting Software

The nesting software helps you automatically arrange graphics and generate cutting files.

D. Prototype Software

If you used to cut fabric manually and have tons of template sheets, you can use our prototype system. It will take pictures of your template and save it digitally that you can use on the laser machine software directly

E. Fume Extractor

If you want to laser-cut plastic-based fabric and worry about toxic fumes, then an industrial fume extractor can help you solve the problem.

Our CO2 Laser Cutting Machine Recommendations

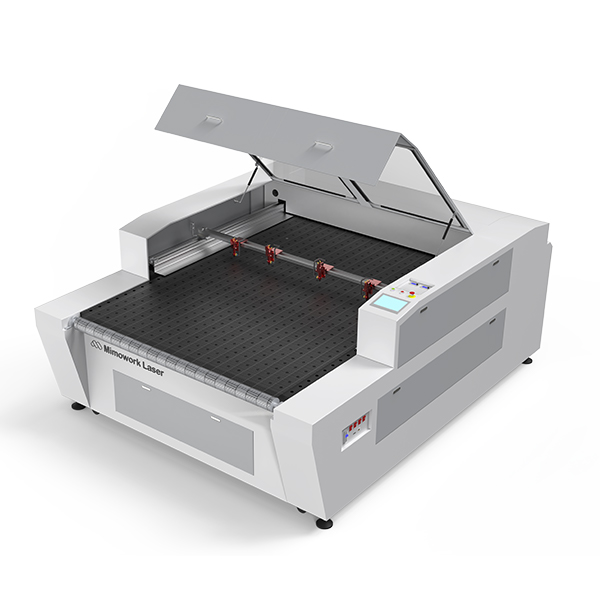

The Mimowork’s Flatbed Laser Cutter 160 is mainly for cutting roll materials. This model is especially R&D for soft materials cutting, like textile and leather laser cutting.

You can choose different working platforms for different materials. Moreover, two laser heads and the auto feeding system as MimoWork options are available for you to achieve higher efficiency during your production.

The enclosed design from the fabric laser cutting machine ensures the safety of laser use. The emergency stop button, tricolour signal light, and all electrical components are installed strictly according to CE standards.

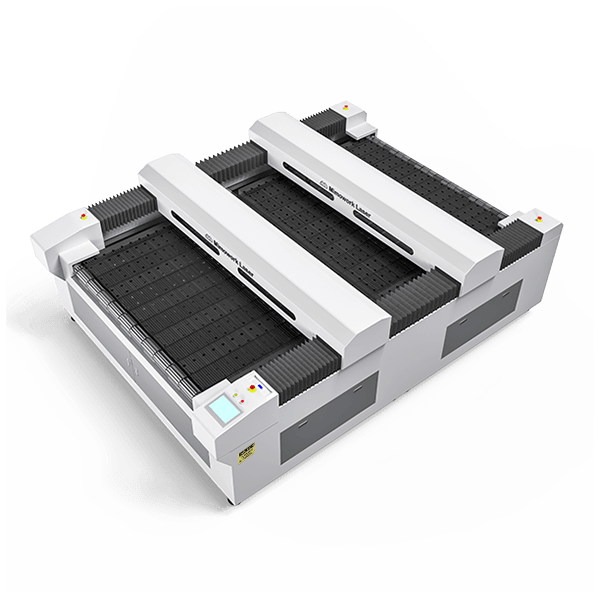

Large format textile laser cutter with conveyor working table – the fully automated laser cutting directly from the roll.

The Mimowork’s Flatbed Laser Cutter 180 is ideal for cutting roll material (fabric & leather) within the width of 1800 mm. The width of fabrics used by various factories will be different.

With our rich experiences, we can customize the working table sizes and also combine other configurations and options to meet your requirements. For the last decades, MimoWork has focused on developing and producing automated laser cutter machines for fabric.

The Mimowork’s Flatbed Laser Cutter 160L is researched and developed for large format coiled fabrics and flexible materials like leather, foil, and foam.

The 1600mm * 3000mm cutting table size can be adapted to most of ultra-long format fabric laser cutting.

The pinion and rack transmission structure guarantees stable and precise cutting results. Based on your resistant fabric like Kevlar and Cordura, this industrial fabric cutting machine can be equipped with a high-power CO2 laser source and multi-laser-heads to ensure production efficiency.

Want to know more about our Fabric Laser Cutting Machines?

Post time: Jan-20-2023