Glass Laser Engraving Machine (The Best of 2024)

A glass laser engraving machine utilizes a focused laser beam to mark or etch designs into glass permanently.

This technology goes beyond mere surface engraving, allowing for the creation of stunning sub-surface engravings in crystal.

Where the design is etched beneath the surface, resulting in a captivating 3D effect.

The large-format 3d glass laser engraving machine is designed for outdoor and indoor space decoration purposes. This 3D laser engraving technology is widely used in large-format glass decoration, building partition decoration, household articles, and art photo ornaments.

Max Engraving Range: 1300*2500*110mm

Laser Wavelength: 532nm

Engraving speed: ≤4500 points/s

Dynamic Axis Response Time: ≤1.2ms

Want to Know More about Glass Engraving Machine?

We Can Help!

The crystal laser engraver takes the diode laser source to produce the green laser 532nm which can pass through the crystal and glass with high optical clarity and create a perfect 3D model inside by laser impact.

Max Engraving Range: 300mm*400mm*150mm

Max Engraving Speed: 220,000 dots/min

Repetition Frequency: 4K HZ(4000HZ)

Resolution: 800DPI -1200DPI

Focus Diameter: 0.02mm

Finding the Best Glass Etching Machine for your Needs?

We Can Help!

The One & Only Solution you will ever need for subsurface laser engraving crystal, packed to the brim with the latest technologies with different combinations to meet your ideal budgets.

Max Engraving Size (mm): 400*600*120

No Tilling Area*: 200*200 Circle

Laser Frequency: 4000Hz

Point Diameter: 10-20μm

No Tilling Area*: The area where the image will not be split into different sections when engraved, Higher = Better.

Learn More about 3D Laser Engraving

3D Laser Crystal Engraving How it Works?

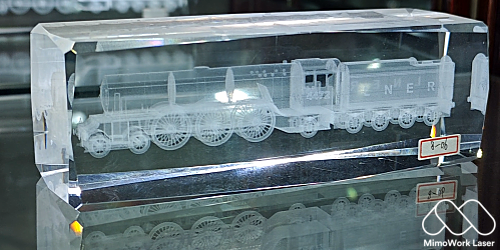

3D Glass Picture Cube with a Train Engraved Inside

The laser beam, directed by a computer-controlled system, interacts with the glass material precisely. In surface engraving, the laser beam removes a thin layer of the glass, creating the desired design.

For sub-surface engraving, the laser beam is focused deeper into the crystal, creating microscopic fractures within the material. These fractures, visible to the naked eye, scatter light differently, resulting in the 3D effect.

Subsurface Laser Engraving (EXPLAINED in 2 Minutes)

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Advantages of Sub-Surface Engraving:

3D Laser Engraving of Loong

Enhanced Durability: The design is protected within the crystal, making it resistant to scratches and wear.

Stunning Depth and Detail: The 3D effect adds depth and dimension to the design, making it visually captivating.

Variety of Applications: Sub-surface engraving is ideal for creating intricate designs on crystal trophies, awards, jewelry, and decorative items.

The power and precision of the laser beam can be adjusted to achieve different engraving depths and effects. This allows for the creation of intricate designs with varying levels of detail and clarity.

The technology of glass laser engraving continues to evolve, with advancements in laser technology and software leading to even more sophisticated and intricate designs.

Want to Create Truly Unique and Breathtaking Pieces

With Glass Laser Engraving Machine, the Future is Now

Post time: Aug-23-2024