A Guide To Laser Cut Cordura

Introduction:

Key Things to Know Before Diving In

Laser cutting Cordura provides a precise, efficient, and versatile method for creating a wide variety of products and designs. This guide delves deeply into the principles, advantages, and practical techniques of laser cutting Cordura.

Table of Contents

Introduction To Laser Cutting Cordura

▶ What Is Cordura And Laser Cut Cordura?

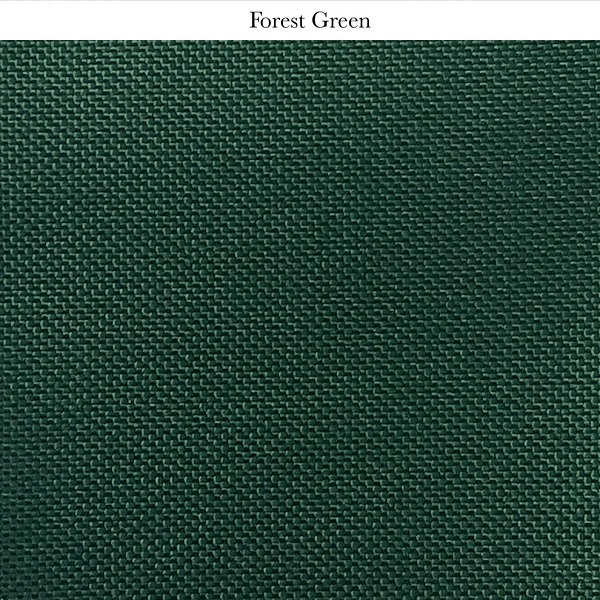

Forest Green Cordura

Cordura is a brand of high-performance synthetic textiles originally developed by the DuPont Corporation. It is mainly made of nylon 6.6, a particularly robust and abrasion-resistant material. Renowned for their resistance to abrasions, tears, and scuffs, Cordura fabrics are an excellent choice for a wide range of applications, including clothing, military gear, outdoor equipment, and marine products.

Laser cutting machines enable Cordura fabrics and other synthetic materials to be cut swiftly and precisely. The heat from the laser beam seals the cut edges, eliminating the need for additional edge treatment. Since there is no contact with the material during laser processing, textiles can be processed in any direction without mechanical deformation, regardless of the fabric's structure.

▶ Why Cut Cordura With Laser?

Precise Cuts: Produces clean, sharp edges without fraying, reducing the need for post-processing.

Versatility: Suitable for a wide range of applications, from small-scale custom projects to mass production.

Speed and Efficiency: Allows for high-speed cutting, significantly increasing productivity.

Consistency: Ensures uniform results for complex designs, maintaining quality across all pieces.

Clean Edge of Laser Cutting Cordura

▶ Applications Of Laser Cut Cordura

Fashion: Custom clothing, accessories, and footwear with intricate designs.

Automotive: Upholstery, seat covers, and interior components.

Military and Outdoor Gear: Backpacks, tents, and protective equipment.

Home Furnishings: Upholstered furniture, cushions, and decorative items.

Sports Equipment: Customized gear, protective padding, and accessories

Smooth Result of Laser Cutting Cordura

Advantages Of Laser Cutting Cordura

▶ Edge Quality And Material Integrity

Cutting and sealing at the same time : Laser cutting has the function of "cutting and sealing" at the same time. The heat from the laser beam can seal the edges of the fabric during the cutting process. This effectively prevents fraying and reduces the generation of lint. For example, when cutting fabrics like nylon or polyester, the sealed edges are smooth and clean, which enhances the overall visual appeal of the finished product.

No physical contact cutting : When cutting single - or multi - layered materials, laser cutting does not require physical contact. This reduces defects caused by wrinkling and pulling. As a result, the material maintains its original shape and performance, and there is no need for additional edge treatment.

▶ Efficiency And Cost - effectiveness

High - speed cutting : Laser cutting is a fast and efficient way to cut fabric. Especially when dealing with large quantities or complex shapes, it can significantly improve production efficiency. For example, in the mass - production of clothing, laser cutting can quickly complete the cutting of a large number of fabric pieces.

• Automation and labor - saving : Laser cutting can be automated, which helps reduce labor costs and increase productivity. With automated feeding and cutting systems, the production process becomes more streamlined. And because there is no tool wear in the laser beam optical and contact - less processing, it also reduces the cost of tool replacement and maintenance.

Laser Cut Cordura: Welded Cutting Edge

▶ Edge Quality And Material Integrity

High - speed cutting : Laser cutting is a fast and efficient way to cut fabric. Especially when dealing with large quantities or complex shapes, it can significantly improve production efficiency. For example, in the mass - production of clothing, laser cutting can quickly complete the cutting of a large number of fabric pieces.

Versatile cutting capabilities : It has a high degree of flexibility. Lasers can cut any size and shape, as well as perform marking for permanent identification. Whether it's cutting large - scale fabric pieces or small, delicate parts, laser cutting can handle it with ease. And the same laser head can be used for a variety of fabrics such as nylon, cotton, polyester, and polyamide, with only minor changes to its parameters.

Any Ideas About Laser Cutting Cordura, Welcome To Discuss With Us!

Detailed Process Steps About Laser Cut Corura

Laser cutting Cordura is a precise and efficient method for creating detailed designs, but achieving optimal results requires understanding the materials and the process. Here’s a step-by-step guide that includes important considerations for working with Cordura.

▶ Process Of Laser Cutting Cordura

1. Choose a CO2 laser cutter with a power range of 100 to 300 watts, which is generally appropriate for most Cordura fabrics.

2. Follow the manufacturer's instructions carefully, including all safety precautions.

3. Place the Cordura fabric on the laser cutter bed and secure it in place. You can use magnetite at the corners of the fabric sheet to fix it.

4. Use vector - based software such as Adobe Illustrator or CorelDRAW to design the cutting pattern. Ensure that the file size is correct and the cut lines are set to the proper settings for the laser cutter.

5. Import the cutting file into the laser cutting software. Then adjust the cutting parameters, including the laser speed, power, and the number of passes required to cut through the Cordura material. If the Cordura patch has an adhesive backing, you need to use higher power and increase the air blowing system.

6. Adjust the focus height and align the laser to the exact position where you want to cut the fabric.

7. Start the laser cutter and let it complete the cutting process.

8. After cutting, remove the Cordura fabric from the laser cutter bed and carefully check the edges for any signs of fraying or damage.

▶ More Information About CO2 Laser Cutter

How about Laser Cutting 500D Cordura Fabric?

This video demonstrates the capabilities of an industrial CO2 laser cutter on 500D Cordura fabric, showcasing fast, clean cuts with smooth edges.

The 150W laser is ideal for synthetic fabrics like Cordura, making it perfect for creating tactical vests and other high-performance gear.

Whether you're in the tactical gear, outdoor apparel, or automotive industries, this video highlights the efficiency and reliability of our fabric laser cutting machine.

Factors Influencing Laser Cutting Cordura

▶ 1. Type Of Laser Cutter

The type of laser cutter you use is one of the most crucial factors influencing the results. Different manufacturers produce various models, each designed for specific applications. Selecting the right machine involves understanding the material and intended use.

▶ 2. Laser Cutting Machine Settings

- Power: Determines the intensity of the laser beam. Higher power is needed for thicker materials or deeper cuts.

- Speed: Refers to how fast the laser moves along the material. Adjusting speed ensures accuracy and prevents overheating or burning.

- Frequency: Influences the number of laser pulses per second, impacting the cut's precision.

▶ 3. Laser Cutter Speed And Power

- Speed: Refers to how quickly the laser moves across the X and Y axes. A higher speed reduces cutting time but may compromise precision for intricate designs.

- Power: Indicates the strength of the laser beam. Increased power enables cutting through thicker materials and produces deeper engravings.

▶ 4. Cordura Thickness

- A CO2 laser cutter with a power of 100 to 300 watts should be suitable for most Cordura fabrics.

General Tips For Laser Cutting Cordura

1. Never Leave the Machine Unattended

Cordura is highly flammable when exposed to laser cutting, making constant supervision essential.

2. Choose the Right Type of Cordura

Select the appropriate Cordura type for your specific application.

3. Elevate the Cordura

Use supports or spacers to lift the Cordura off the cutting table. Elevation helps eliminate backside reflections, which can cause unwanted marks or damage to the material.

4. Machine fume extraction installation

By installing a fume extractor on the machine, it is possible to avoid excessive smoke that may affect the cutting effect.

Laser Cutting Cordura FAQs

▶ 1. How Does Laser Cutting Cordura?

The agile and potent laser head releases a fine laser beam to melt the edges, thus realizing laser cutting of Cordura® fabric while sealing the edges.

▶ 2. What Fabrics Are Safe For Laser Cutting?

The optimal materials for laser cutting are those that do not emit toxic fumes, combust cleanly, and produce accurate results. Natural fibers, such as cotton, and specific synthetic fibers, like polyester, can be safely processed by laser cutting when the appropriate conditions are met.

▶3. What Type Of Laser Cutter Can Cut Cordura?

CO₂ laser cutters are the most effective for cutting Cordura. These emit laser beams in the infrared region, which Cordura can absorb, regardless of color. High-power CO₂ lasers can cut through Cordura in a single pass, depending on the thickness.

▶4. Why Choose A Laser Cutter For Cordura Instead Of Conventional Methods?

Laser cutting offers precise, smooth, and constant cutting edges with no contact with the material, reducing breakage. It is highly flexible, minimizes material waste, and does not cause tool wear. Additionally, laser cutting can include labeling and fine detailing, offering superior quality compared to conventional methods.

▶5. Can I Laser Cut Cordura Myself?

Yes. You can laser cut Cordura as long as you have the right materials, tools, and expertise. However, for professional-quality results, it’s often recommended to hire qualified professionals or specialized companies. These businesses have the necessary equipment and skilled staff to ensure high-standard results.

▶8. How Does The Machine Ensure High Precision?

Some laser machines are equipped with CCD cameras, which can help you precisely position the design on the fabric and ensure correct cutting. However, if there are other methods that can accurately position the design, it may not be necessary. If you often cut complex or intricate designs, a CCD camera can be a valuable addition to your laser machine.

CCD Camera

Recommended Machine For Laser Cut Cordura

To achieve the best results when cutting polyester, choosing the right laser cutting machine is crucial. MimoWork Laser offers a range of machines that are ideal for laser cutting cordura, including:

• Working Area (W *L): 1600mm*3000mm

• Laser Power: 150W/300W/500W

Conclusion

Laser cutting Cordura is a precise, efficient, and versatile method with clean, sealed edges, minimal post-processing, high-speed precision cutting, non-contact operation reducing waste and tool wear.To get the best results, use a CO2 laser cutter (100 - 300 watts), adjust machine settings (power, speed, frequency), and follow steps like fabric prep, creating a vector-based cutting file, loading and adjusting it, then inspecting.

Cutting quality is affected by the laser cutter type, settings, and Cordura thickness, with CCD cameras aiding precision for complex designs. It's a top choice for various industries, offering better quality and efficiency than traditional methods.

Related Links

Any Questions About Laser Cutting Machine For Cordura?

Post time: Feb-28-2025