Handheld Laser Weld: What to Expect in 2024

What is Handheld Laser Weld?

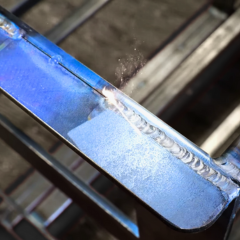

Handheld laser welding utilizes a portable laser device to join materials, typically metals.

Handheld laser welding allows for greater maneuverability and precision, and produces a high-quality, clean weld with minimal heat input, reducing distortion and the need for extensive post-weld processing.

Operators can easily adjust the power and speed of the laser, enabling tailored settings for different materials and thicknesses.

Table of Content:

Are Handheld Laser Welders any Good?

Let's Clear Some Common Misunderstandings

Handheld laser welders have gained popularity in various industries.

In general, handheld laser welders are Pretty Good.

However, there are several common misunderstandings about their effectiveness and reliability, here are some of them:

Common Misunderstandings:

Handheld Fiber Laser Welding Steel

Limited Power and Penetration:

A frequent belief is that handheld laser welders lack the power necessary for heavy-duty applications, making them unsuitable for thicker materials.

High Cost with Low Value:

Some skeptics argue that the initial investment in handheld laser welding equipment outweighs the benefits, suggesting it’s not worth the expense.

Difficult to Operate:

There’s a notion that handheld laser welders require extensive training and skill, making them impractical for everyday use.

Why These Misunderstandings Occur:

These misconceptions often stem from a lack of familiarity with the technology.

Traditional welding methods, such as MIG or TIG, have been the industry standard for years, leading to skepticism about newer techniques.

Additionally, early models of handheld laser welders were less powerful and more expensive, contributing to a negative perception.

Modern handheld laser welders often exceed 1000 watts in power output. This enables them to weld materials up to several millimeters thick effectively.

For instance, tests have shown that handheld laser welders can successfully join stainless steel and aluminum with minimal distortion, even in complex geometries.

While some training is necessary, many operators can get up to speed in just a few hours, and find it easier to use than traditional welding equipment.

Feedback from users indicates that once trained, operators can achieve high-quality welds consistently, often in less time than conventional methods.

Can Laser Welding be Done by Hand?

With Specific Scenarios Where it Excels

Yes, laser welding can indeed be done by hand, and this capability opens up a range of applications that benefit from the precision and flexibility of handheld tools.

Scenarios and Applications:

Handheld Laser Weld for Stainless Steel

Automotive Repairs

A small auto repair shop specializes in restoring vintage cars. The owner often encounters intricate metalwork, including patching rusted areas on body panels.

Handheld laser welding allows the technician to access tight spaces without damaging surrounding areas. The precise control of the laser minimizes heat input, reducing warping in the thin metal panels typical of vintage cars.

Using a handheld laser welder, the technician can create strong, clean welds with minimal distortion, whereas traditional welding methods might introduce more heat and lead to undesirable results.

Handheld Laser Applications in Construction

Field Repairs in Construction

A construction crew working on-site encountered unexpected damage to some of the structural steel components.

Using a handheld laser welder, the crew can perform on-the-spot repairs, ensuring that the project schedule remains on track.

Handheld laser welding is particularly advantageous here because it creates strong bonds without generating excessive heat, which is crucial for maintaining the integrity of the existing structure.

Looking for a New Practical Effective Welding Solution?

Handheld Laser Weld is an Excellent Choice

Are Laser Welders Legal?

A Breakdown of Specific Regulations and Considerations

Yes, laser welders are LEGAL to use. But What Makes a Laser Welder illegal?

Safety Standards Compliance

Laser welders must adhere to safety regulations set by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States.

If a laser welder does not meet these standards—such as proper shielding, eye protection, and safety interlocks—it may be deemed illegal for use in a workplace.

Environmental Regulations

Some laser welding processes may produce harmful fumes or emissions. If a facility does not have appropriate ventilation systems or fails to meet local environmental regulations, the use of a laser welder may be restricted or illegal.

Industrial Applications

In industrial settings, using laser welders often requires additional permits.

For example, if a company is using a laser welder in a manufacturing process that involves hazardous materials, they may need to obtain special permits from environmental or safety regulatory bodies.

Specialized Industries

Certain industries, such as aerospace or medical device manufacturing, have stringent regulations.

Companies in these sectors may need to provide documentation proving that their laser welding processes comply with industry-specific standards, such as ISO certifications or FDA approvals.

Insurance and Liability

Some businesses overlook the necessity of obtaining liability insurance for using laser welders.

If an accident occurs due to improper use or equipment failure, not having adequate insurance can lead to significant legal consequences.

Is Laser Welding as Strong as MIG Welding?

When it comes to joining metals, one of the popular methods is MIG (Metal Inert Gas) welding.

Each technique has its advantages, but how do Handheld Laser Weld & MIG Welding compare in terms of strength?

Is Laser Welding as Strong as TIG Welding?

Laser welding and TIG (Tungsten Inert Gas) welding are both renowned for their precision and quality in metal joining.

But how do they stack up against each other in terms of strength?

In this video, we’ll dive into the key differences in weld performance, material compatibility, and overall durability between laser and TIG welding.

Why are Laser Welders so Expensive?

Often Perceived as Expensive, Leading to Misunderstandings

Many people assume that all laser welders are prohibitively expensive based on the price of high-end industrial models.

This overlooks the fact that there are various types of laser welders, including handheld and portable options, which are significantly more affordable.

Industrial Laser Welders vs. Handheld Models

For Industrial Laser Welders:

High-end laser welders used in automated settings, such as those integrated with robotic arms in manufacturing lines, cost very differently than Handheld Portable Laser Welders.

For Handheld Portable Laser Welders:

In contrast, portable laser welders, which are more accessible to small businesses and individual users, typically start from $4,000 for a decent setup. While they may lack some of the advanced features of industrial models, they still provide excellent performance for a variety of applications, such as automotive repairs and custom metalwork.

Does Laser Welding Need Filler?

Do you Need Gas for Laser Welding?

When considering laser welding, a common question arises:

Does it Require Filler Material?

A key consideration in laser welding is:

Whether gas is required during the process.

This article explores the circumstances under which filler may be necessary, the advantages and disadvantages of using it, and how it impacts the welding process.

While also examines the role of gas in laser welding, including its benefits, potential alternatives, and specific applications where gas may or may not be necessary.

Handheld Fiber Laser Welding (Handheld Laser Weld)

A Valuable Addition to the Handheld Laser Weld Landscape

Small Laser Welder Makes Welding Cost-effective & Affordable

With a compact and small machine appearance.

The portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight.

And convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles.

An optional automatic wire feeding system makes laser welding operation easier and that is friendly for beginners.

5 Things About Laser Welding (That you Missed)

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Handheld Laser Weld is an Excellent Choice for Manual Welding Tasks

And the Future Starts with You!

Post time: Sep-10-2024