How to Cut Sandpaper More Efficiently?

sandpaper cutting machine

Cutting sandpaper to the right size and shape is a crucial step in many industrial and craft applications.

And there are some requirements for cutting small holes in sandpaper, that are used to extract the dust.

Whether you’re preparing sandpaper for hand sanding, machine sanding, or specialized projects, choosing the right cutting tool can significantly impact efficiency, precision, and safety.

This page will explore the types of sandpaper, their applications, and the best tools for cutting sandpaper in both batch and customized production settings.

Main Grit Types

Sandpaper comes in various grit types(abrasive), each designed for specific applications. The most common types include aluminum oxide, silicon carbide, ceramic, and garnet sandpaper. Each type has unique properties suitable for different tasks:

• Aluminum Oxide: Durable and versatile, ideal for wood and metal sanding.

• Silicon Carbide: Sharp and hard, perfect for cutting hard materials like glass and plastic.

• Ceramic: Extremely durable and effective for heavy-duty sanding and grinding.

• Garnet: Softer and more flexible, typically used for fine woodworking.

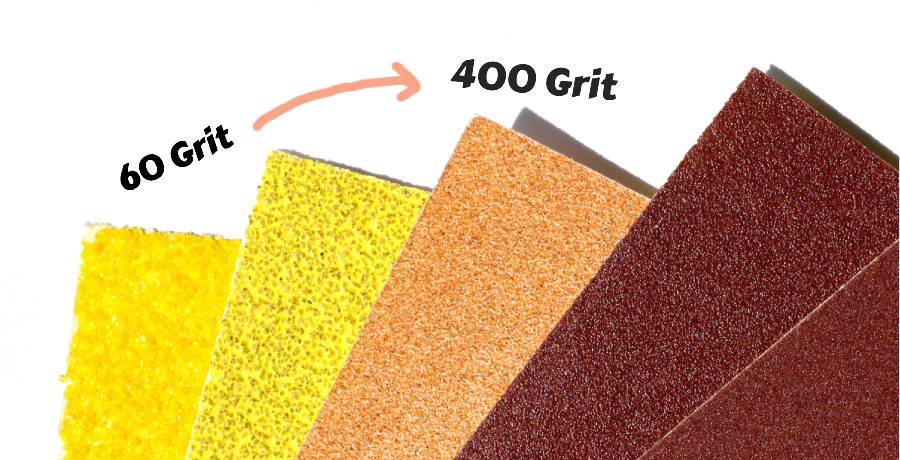

What are the 3 grades of sandpaper?

Sandpaper is split into grades such as fine, coarse and medium and each of these grades contains different levels that are defined by what are known as grit.

• Coarse: For heavy sanding and stripping, you need coarse sandpaper grit measuring 40- to 60-grit.

• Medium: For smoothing surfaces and removing small imperfections, choose medium sandpaper from 80- to 120-grit sandpaper.

• Fine: To finish surfaces smoothly, use a super fine sandpaper with 400- to 600-grit.

Sandpaper is used across a wide range of industries including woodworking, automotive, metalworking, and construction.

It’s essential for tasks such as smoothing surfaces, removing paint or rust, and preparing materials for finishing.

Utility Knife

For manual cutting, a utility knife with a straightedge is a simple yet effective method.

It’s often used in smaller workshops where cutting precision and volume are manageable by hand.

Dremel Tool

A Dremel tool with a cutting attachment can be used for smaller, detailed cuts.

It’s more suited for hobbyists or small-scale production where flexibility is needed.

Rotary Paper Cutter

Rotary paper cutters are useful for making straight cuts in sandpaper sheets.

Similar to a paper trimmer, it uses a rotating blade to cut the sandpaper.

As a manual cutting tool, the rotary paper cutter can't guarantee the cutting precision and speed.

Laser Cutter

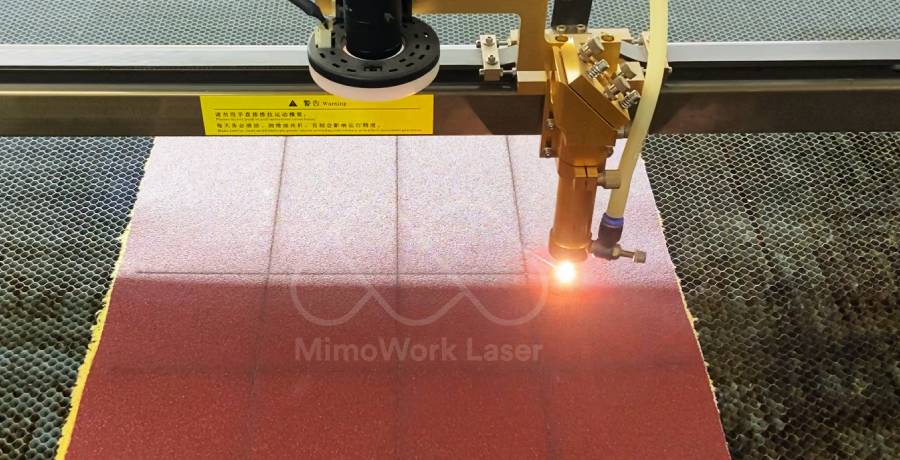

Laser cutters are highly precise, making them ideal for custom shapes and intricate designs.

They use a focused beam of light to cut through sandpaper, ensuring clean edges without fraying.

Laser cutter is versatile of cutting small holes and cutting into various shapes and sizes.

Thanks to the CNC system and advanced machine configuration, the sandpaper cutting quality and cutting efficiency can be realized in one machine.

Die Cutter

Die cutters use a pre-shaped die to punch out specific shapes from sheets or rolls of sandpaper.

They are efficient for high-volume production runs where uniformity is essential.

The limit of the die cutter is the wear and tear of abrasive tools. If we want to cut new shapes and new designs of sandpaper, we need to purchase the new dies. That's expensive.

Require High Precision and Customization:

If the cutting precision and whether it can be customized are your concern, the Laser Cutter is your ideal choice.

Laser cutting sandpaper offers unmatched precision, versatility, and efficiency.

Ideal for both small-scale and large-scale production where high-quality, intricate designs are required.

The initial investment is higher, but the benefits in terms of precision and flexibility make it worthwhile.

Concern High Efficiency & Production Output

Speaking of the cutting efficiency, the die cutter is the winner cause it cut the sandpaper by the pre-shaped dies.

If you have the same design and pattern, the die cutter can quickly finish the cutting. That's suitable for mass production for the same sandpaper design.

But if you have various requirements for sandpaper shapes, dimensions, design patterns, the die cutter is not the best compared with laser cutter.

New design requires new die, that's time-consuming and expensive for die cutting. In the contrary, laser cutter can meet customized and various shapes cutting in one machine.

For Budget-conscious Operation

Considering the machine cost, the manual tools like rotary cutter and Dremel is more cost-saving, and have certain operation flexibility.

They are suitable for smaller operations or where budget constraints are a significant factor.

While the manual lack the precision and efficiency of laser cutters, they are accessible and cost-effective for simpler tasks.

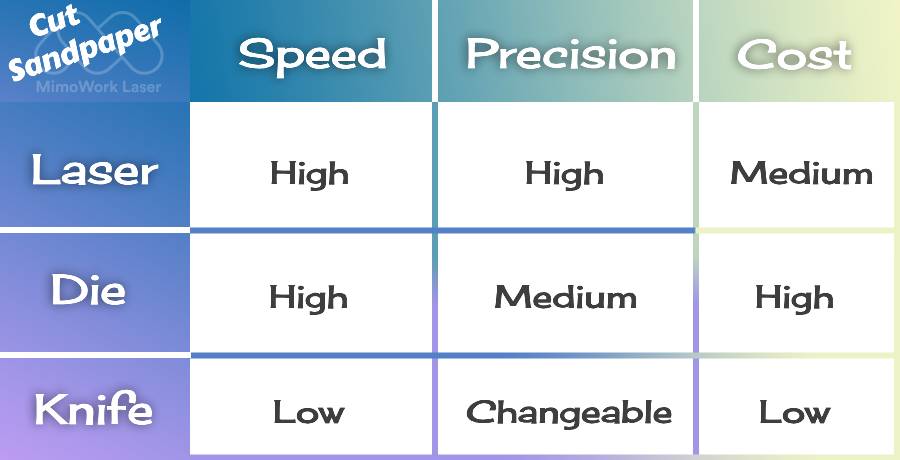

Comparison of the Three Tools

For cutting sandpaper, the choice of tool depends largely on the specific needs of the operation.

Laser cutters stand out as the best overall choice for their precision, versatility, and efficiency, especially when dealing with intricate designs and customized orders.

Die cutters are effective for high-volume, consistent production.

While rotary cutters offer a budget-friendly option for smaller, less complex tasks.

By evaluating your specific requirements and production scale, you can select the most suitable tool to achieve optimal results in cutting sandpaper.

Custom-Shaped Sandpaper for Specialized Tools

Power Sanders: Laser cutting allows for the precise creation of sandpaper that fits specific power sander shapes, such as orbital, belt, and disc sanders. This ensures optimal performance and efficiency.

Detail Sanders: Custom shapes can be cut to fit detail sanders used in intricate woodworking or finishing tasks.

Precision-Cut Sandpaper for Industrial Use

Automotive Industry: Laser-cut sandpaper is used for finishing and polishing automotive components, where precise shapes and sizes are critical for consistent results.

Aerospace Industry: The aerospace industry requires high precision for surface preparation and finishing. Laser-cut sandpaper meets these stringent standards.

Craft and Hobby Projects

DIY Projects: Hobbyists and DIY enthusiasts benefit from laser-cut sandpaper for detailed work on various materials, including wood, metal, and plastic.

Model Making: Precision-cut sandpaper is ideal for model makers who need small, intricately shaped pieces for fine sanding tasks.

Furniture and Woodworking

Furniture Restoration: Laser-cut sandpaper can be tailored to fit specific contours and shapes of furniture pieces, allowing for detailed restoration work.

Carpentry: Woodworkers can use custom-shaped sandpaper for detailed sanding of carvings, edges, and joints.

Medical and Dental Applications

Orthopedic Sanding: Custom-shaped sandpaper is used in the medical field for preparing orthopedic devices and prosthetics.

Dental Tools: Precision-cut sandpaper is utilized in dental practices for polishing and finishing dental prosthetics and appliances.

Sandpaper with Custom Hole Patterns

Dust Extraction Systems: Laser cutting allows for precise placement of holes in sandpaper to align with dust extraction systems, enhancing efficiency and cleanliness during sanding.

Improved Performance: Custom hole patterns can improve the performance of sandpaper by reducing clogging and extending its lifespan.

Art and Design

Creative Projects: Artists and designers use laser-cut sandpaper for unique art pieces, where precision and intricate designs are required.

Textured Surfaces: Custom textures and patterns can be created on sandpaper for specific artistic effects.

Instrument & Sports Gear

Instrument: Laser-cut sandpaper is used in the production of guitars to smooth and finish the body, neck, and fretboard. This ensures a high-quality finish and comfortable playability.

Sports Gear: For example, the skateboards often require sandpaper, specifically known as grip tape, to be applied to the deck for enhanced traction and control.

Perfect for Cutting, Perforating, Engraving

Laser Cutter for Sandpaper

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

|

Weight |

620kg |

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Learn more about the laser cutting sandpaper

Any Questions about Laser Cut Sandpaper?

Post time: Jul-02-2024