From Box to Art: Laser Cut Cardboard

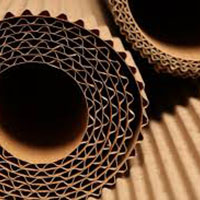

"Want to turn ordinary cardboard into extraordinary creations?

Discover how to laser cut cardboard like a pro – from choosing the right settings to crafting stunning 3D masterpieces!

What's the secret to perfect cuts without the burnt edges?"

Cardboard

Table of Content:

Cardboard can be laser cut, and it is actually a popular material used in laser cutting projects due to its accessibility, versatility, and cost-effectiveness.

Cardboard laser cutters are able to create intricate designs, shapes, and patterns in cardboard, making it a great option for creating a variety of projects.

In this article, we will discuss why you should laser cut cardboard and share some of the projects that can be done with a laser cutting machine and cardboard.

Introduction to Laser Cutting Cardboard

1. Why Choose Laser Cutting for Cardboard?

Advantages over Traditional Cutting Methods:

• Precision:Laser cutting offers micron-level accuracy, enabling intricate designs, sharp corners, and fine details (e.g., filigree patterns or micro-perforations) that are difficult with dies or blades.

Minimal material distortion since there’s no physical contact.

• Efficiency:No need for custom dies or tooling changes, reducing setup time and costs—ideal for prototyping or small batches.

Faster processing for complex geometries compared to manual or die-cutting.

• Complexity:

Handles intricate patterns (e.g., lace-like textures, interlocking parts) and variable thicknesses in a single pass.

Easy digital adjustments (via CAD/CAM) allow rapid design iterations without mechanical constraints.

2. Cardboard Types and Characteristics

1. Corrugated Cardboard:

• Structure: Fluted layer(s) between liners (single/double-wall).

• Applications: Packaging (boxes, inserts), structural prototypes.

Cutting Considerations:

Thicker variants may require higher laser power; risk of charring on edges.

Flute direction affects cut quality—cross-flute cuts are less precise.

2. Solid Cardboard (Paperboard):

• Structure: Uniform, dense layers (e.g., cereal boxes, greeting cards).

• Applications: Retail packaging, model-making.

Cutting Considerations:

Smooth cuts with minimal burn marks at lower power settings.

Ideal for detailed engraving (e.g., logos, textures).

3. Gray Board (Chipboard):

• Structure: Rigid, non-corrugated, often recycled material.

• Applications: Book covers, rigid packaging.

Cutting Considerations:

Requires balanced power to avoid excessive burning (due to adhesives).

Produces clean edges but may need post-processing (sanding) for aesthetics.

Process of CO2 Laser Cutting Cardboard

Cardboard Furniture

▶ Design Preparation

Create cutting paths with vector software (e.g. Illustrator)

Ensure closed-loop paths without overlaps (prevents scorching)

▶ Material Fixation

Flatten and secure cardboard on cutting bed

Use low-tack tape/magnetic fixtures to prevent shifting

▶ Test Cutting

Perform corner test for full penetration

Check edge carbonization (reduce power if yellowing)

▶ Formal Cutting

Activate exhaust system for smoke extraction

Multi-pass cutting for thick cardboard (>3mm)

▶ Post-Processing

Brush edges to remove residue

Flatten warped areas (for precision assemblies)

Video of Laser Cutting Cardboard

Kitten loves it! I Made A Cool Cardboard Cat House

Discover how I made an amazing cardboard cat house for my furry friend - Cola!

Laser Cut Cardboard is so easy and time-saving! In this video, I'll show you how I used a CO2 laser cutter to precisely cut cardboard pieces from a custom-designed cat house file.

With zero costs and easy operation, I assembled the pieces into a fantastic and cozy home for my cat.

DIY Cardboard Penguin Toys with Laser Cutter !!

In this video, we’ll dive into the creative world of laser cutting, showing you how to craft adorable, custom penguin toys using nothing but cardboard and this innovative technology.

Laser cutting allows us to create perfect, precise designs with ease. We’ll walk you through the process step-by-step, from selecting the right cardboard to configuring the laser cutter for flawless cuts. Watch as the laser glides smoothly through the material, bringing our cute penguin designs to life with sharp, clean edges!

Recommended Laser Cutting Machine on Cardboard

| Working Area (W *L) | 1000mm * 600mm (39.3” * 23.6 ”)1300mm * 900mm(51.2” * 35.4 ”)1600mm * 1000mm(62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 40W/60W/80W/100W |

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

FAQ

Yes, a fiber laser can cut cardboard, but it is not the ideal choice compared to CO₂ lasers. Here’s why:

1. Fiber Laser vs. CO₂ Laser for Cardboard

- Fiber Laser:

- Primarily designed for metals (e.g., steel, aluminum).

- Wavelength (1064 nm) is poorly absorbed by organic materials like cardboard, leading to inefficient cutting and excessive charring.

- Higher risk of burning/scorching due to intense heat concentration.

- CO₂ Laser (Better Choice):

- Wavelength (10.6 μm) is well-absorbed by paper, wood, and plastics.

- Produces cleaner cuts with minimal burning.

- More precise control for intricate designs.

CO₂ Laser Cutters

Why?

- Wavelength 10.6µm: Ideal for cardboard absorption

- Non-contact cutting: Prevents material warping

- Best for: Detailed models,cardboard letters, intricate curves

- Die Cutting:

- Process: A die (like a giant cookie cutter) is made in the shape of the box’s layout (called a "box blank").

- Use: It's pressed into sheets of corrugated cardboard to cut and crease the material at the same time.

- Types:

- Flatbed Die Cutting: Great for detailed or small-batch jobs.

- Rotary Die Cutting: Faster and used for high-volume production.

- Slitter-Slotter Machines:

- These machines cut and crease long sheets of cardboard into box shapes using spinning blades and scoring wheels.

- Common for simple box shapes like regular slotted containers (RSCs).

- Digital Cutting Tables:

- Use computerized blades, lasers, or routers to cut custom shapes.

- Ideal for prototypes or small custom orders—think short-run e-commerce packaging or personalized prints.

When choosing cardboard for laser cutting, the ideal thickness depends on the power of your laser cutter and the level of detail you want. Here’s a quick guide:

Common Thicknesses:

-

1.5mm – 2mm (approx. 1/16")

-

Most commonly used for laser cutting.

-

Cuts cleanly and is sturdy enough for model making, packaging prototypes, and crafts.

-

Works well with most diode and CO₂ lasers.

-

-

2.5mm – 3mm (approx. 1/8")

-

Still laser-cuttable with more powerful machines (40W+ CO₂ lasers).

-

Good for structural models or when more rigidity is needed.

-

Slower cutting speeds and may char more.

-

Cardboard Types:

-

Chipboard / Greyboard: Dense, flat, and laser-friendly.

-

Corrugated Cardboard: Can be laser cut, but the inner fluting makes it harder to get clean lines. Produces more smoke.

-

Mat board / Craft board: Often used for laser cutting in fine arts and framing projects.

Want to invest in Laser Cutting on cardboard?

Post time: Apr-21-2025