How to Laser Cut Clear Acrylic

Tips and Tricks for Perfect Acrylic Cutting

Laser-cutting clear acrylic is a common process used in various industries such as sign-making, architectural modeling, and product prototyping.

The process involves using a high-powered acrylic sheet laser cutter to cut, engrave, or etch a design onto a piece of clear acrylic.

The resulting cut is clean and precise, with a polished edge that requires minimal post-processing.

In this article, we will cover the basic steps of laser cutting clear acrylic and provide some tips and tricks to teach you how to laser cut clear acrylic.

Table of Content:

• Select the Suitable Clear Acrylic

Besides protecting the acrylic from scratching, in selecting acrylic types, there are some things you need to note.

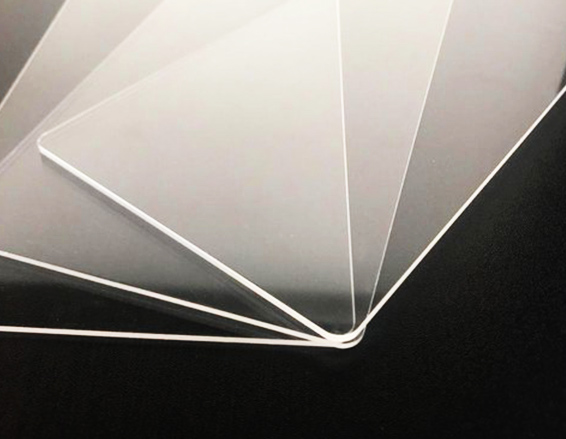

We know there are two types of acrylic sheets: cast acrylic and extruded acrylic.

Cast acrylic is more suitable for laser cutting cause of its hardness and the polished edge after cutting.

But if you are concerned about the cost, extruded acrylic is less expensive, via laser test and careful parameters setting, you can get a great laser-cut acrylic.

• Identify the Clearness of Acrylic Sheet

You can hold the acrylic sheet up to the light, to observe the cloudiness and imperfections. High-quality clear acrylic should be crystal clear with no visible haze or discoloration.

Or you can directly purchase the specific grade of acrylic. Labeled as optically clear or premium grade, the acrylics are specifically designed for applications where clarity is crucial.

• Keep the Acrylic Clean

Before laser cutting clear acrylic, it is important to make sure that the material is properly prepared.

Clear acrylic sheets typically come with a protective film on both sides to prevent scratches and damage during transport and handling.

For thick acrylic, it's important to remove this protective film is necessary before CO2 laser acrylic cutting, as it can cause uneven cutting and melting.

Once the protective film is removed, the acrylic should be cleaned with a mild detergent to remove any dirt, dust, or debris.

• Choose Suitable Acrylic Laser Cutter

Once the clear acrylic is prepared, it is time to set up the laser cutting machine.

The machine that cuts acrylic should be equipped with a CO2 laser that has a wavelength of around 10.6 micrometers.

Choose the laser power and working area according to your acrylic thickness and size.

Usually, the common working formats of acrylic laser cutting machines are small acrylic laser cutter 1300mm * 900mm and large acrylic laser cutting machine 1300mm * 2500mm. That can meet most acrylic cutting requirements.

If you have special acrylic size and cutting pattern, please contact us to get a professional suggestion. Customization of machine sizes and configurations is available.

• Debugging the Machine and Find the Optimal Setting

The laser should also be calibrated to the correct power and speed settings, which may vary depending on the thickness of the acrylic and the desired cutting depth. We suggest testing your material with some scraps first.

The laser should be focused on the surface of the acrylic to ensure precise cutting. How to find the right focal length for your laser cutter, check out the laser tutorial, or learn from the video below.

Before starting the CO2 laser acrylic cutting process, it is important to design the cutting pattern.

This can be done using computer-aided design (CAD) software such as Adobe Illustrator or AutoCAD.

The cutting pattern should be saved as a vector file, which can be uploaded to the laser cutting machine for processing.

The cutting pattern should also include any engraving or etching designs that are desired.

Once the laser for acrylic cutting is set up and the cutting pattern is designed, it is time to start the CO2 laser acrylic cutting process.

The clear acrylic should be securely placed on the cutting bed of the machine, ensuring that it is level and flat.

The laser cutter acrylic sheets should then be turned on, and the cutting pattern should be uploaded to the machine.

The laser cutting machine will then follow the cutting pattern, using the laser to cut through the acrylic with precision and accuracy.

Video: Laser Cut & Engrave Acrylic Sheet

• Use a Low-Power Setting

Clear acrylic can melt and discolor at high power settings.

To avoid this, it is best to use a low-power setting and make multiple passes to achieve the desired cutting depth.

• Use a High-Speed Setting

Clear acrylic can also crack and break at low-speed settings.

To avoid this, it is best to use a high-speed setting and make multiple passes to achieve the desired cutting depth.

• Use a Compressed Air Source

A compressed air source can help to blow away debris and prevent melting during the laser cutting process.

• Use a Honeycomb Cutting Bed

A honeycomb cutting bed can help to support the clear acrylic and prevent warping during the laser cutting process.

• Use Masking Tape

Applying masking tape to the surface of the clear acrylic before laser cutting can help to prevent discoloration and melting.

Laser cutting clear acrylic is a straightforward process that can be done with precision and accuracy using the right equipment and techniques. By following the steps outlined in this article and using the tips and tricks provided, you can achieve the best results when laser cutting clear acrylic for your next project.

1. Can you laser cut clear acrylic?

Yes, you can laser cut clear acrylic.

Laser cutters are well-suited for cutting acrylic due to their precision and ability to create clean, smooth edges.

Cast acrylic and extruded acrylic can be laser cut and engraved.

Due to the precision and heat processing, the laser-cut acrylic has a flame-polished and clean edge, with customized cutting patterns.

2. What laser can cut clear acrylic?

For cutting clear acrylic, a CO2 laser is the most suitable type.

CO2 lasers are highly effective for cutting and engraving acrylic due to their specific wavelength (10.6 micrometers), which is well-absorbed by the material.

With great ventilation system, and high cutting precision, the CO2 laser cutting machine is capable of cutting and engraving acrylic sheets with a clean edge and accurate cutting shape.

3. How to laser engrave acrylic?

To laser engrave acrylic, start by ensuring the acrylic sheet is clean and keep the protective film on.

Set up the laser cutter by focusing the laser and selecting the appropriate power, speed, and frequency settings for the acrylic type and thickness.

Use graphic design software to create your engraving design and convert it into a compatible format.

Position and secure the acrylic sheet on the laser cutter bed, then send the design to the laser cutter and monitor the process.

Video: Customize A LED Display by Laser Engraving Acrylic

Laser Cut Acrylic Signage

Laser Cut Thick Acrylic up to 21mm

Tutorial: Laser Cut & Engrave on Acrylic

Take Your Ideas, Come with Laser Acrylic to Have Fun!

Laser Cut Printed Acrylic? It's Ok!

Not only cutting clear acrylic sheets, the CO2 Laser can cut printed acrylic. With the help of CCD Camera, the acrylic laser cutter feels like having eyes, and directs the laser head to move and cut along the printed contour. Learn more about CCD Camera laser cutter >>

UV-printed acrylic with rich colors and patterns is gradually universal, adding more flexibility and customization. Awesomely, it can also be laser cut accurately with pattern Optical Recognition Systems. Advertising boards, daily decorations, and even memorable gifts made of photo printed acrylic, supported by printing and laser cutting technology, are easy to achieve with high speed and customization. You can laser cut printed acrylic as your customized design, which is convenient and highly efficient.

1. Signage and Displays

Retail Signage: Laser-cut acrylic is often used for creating high-quality, visually appealing signs for retail stores, offering a sleek and professional appearance.

Trade Show Displays: Custom shapes and designs can be easily achieved, making it ideal for creating eye-catching trade show booths and displays.

Wayfinding Signs: Durable and weather-resistant, laser-cut acrylic is perfect for indoor and outdoor directional signage.

2. Interior Design and Architecture

Wall Art and Panels: Intricate designs and patterns can be laser-cut into acrylic sheets, making them perfect for decorative wall panels and art installations.

Lighting Fixtures: Acrylic's light-diffusing properties make it an excellent choice for creating modern lighting fixtures and lamp covers.

3. Furniture and Home Decor

Tables and Chairs: The flexibility of laser cutting allows for the creation of custom acrylic furniture pieces with intricate designs and smooth edges.

Decorative Accents: From picture frames to ornamental pieces, laser-cut acrylic can add a touch of elegance to any home decor.

4. Medical and Scientific Applications

Medical Equipment Housings: Acrylic is used for creating clear, durable housings for medical and laboratory equipment.

Prototypes and Models: Laser-cut acrylic is ideal for producing precise prototypes and models for scientific research and development.

5. Automotive and Aerospace

Dashboard Components: The precision of laser cutting makes it suitable for manufacturing acrylic components for vehicle dashboards and control panels.

Aerodynamic Parts: Acrylic is used for creating lightweight, aerodynamically efficient parts for vehicles and aircraft.

6. Art and Jewelry

Custom Jewelry: Laser-cut acrylic can be used to create unique, personalized jewelry pieces with intricate designs.

Art Pieces: Artists use laser-cut acrylic to produce detailed sculptures and mixed-media art projects.

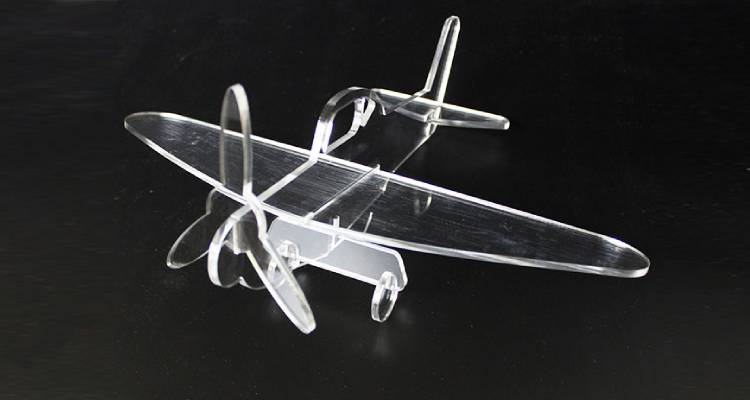

7. Model Making

Architectural Models: Architects and designers use laser-cut acrylic to create detailed and accurate scale models of buildings and landscapes.

Hobby Models: Hobbyists use laser-cut acrylic for creating parts for model trains, planes, and other miniature replicas.

8. Industrial and Manufacturing

Machine Guards and Covers: Acrylic is used for fabricating protective guards and covers for machinery, offering visibility and safety.

Prototyping: In industrial design, laser-cut acrylic is frequently used for creating precise prototypes and components.

Any Questions about the Operation of How to Laser Cut Acrylic?

Post time: Mar-16-2023