How to Laser Cut Cordura Patch?

Cordura patches can be cut into various shapes and sizes, and can also be customized with designs or logos. The patch can be sewn onto the item to provide additional strength and protection against wear and tear. Compared with regular woven label patch, Cordura patch is actually harder to cut since Cordura is a type of fabric that is known for its durability and resistance to abrasions, tears, and scuffs. The majority of laser cut police patch is made of Cordura. It’s the sign of toughness.

Operation Steps – Laser Cut Cordura Patches

To cut Cordura patch with a laser machine, you will need to follow these steps:

1. Prepare the design of the patch in a vector format such as .ai or .dxf.

2. Import the design file into the MimoWork laser cutting software that controls your CO2 laser machine.

3. Set the cutting parameters in the software, including the speed and power of the laser and the number of passes required to cut through the Cordura material. Some cordura patch has adhesive backing, which requires you to use higher power and turn up the air blowing system.

4. Place the Cordura fabric sheet on the laser bed and secure it in place. You can put 4 magnetite on the corner of each Cordura sheet to fix it.

5. Adjust the focus height and align the laser to the position where you want to cut the patch.

6. Start the Cordura cutting laser machine to cut the patch.

What is CCD Camera?

Whether you need a CCD camera on the laser machine depends on your specific requirements. A CCD camera can help you to precisely position the design on the fabric and ensure that it is cut correctly. However, it may not be necessary if you can accurately position the design using other methods. If you frequently cut complex or intricate designs, a CCD camera can be a valuable addition to your laser machine.

What Benefits of Using CCD Camera?

If your Cordura Patch and Police Patch comes with pattern or other design elements, CCD camera is quite useful. can capture an image of the workpiece or the laser bed, which can then be analyzed by the software to determine the position, size, and shape of the material and the location of the desired cut.

The camera recognition system can be used to perform a number of functions, including:

Automatic Material Detection

The camera can identify the type and color of the material being cut and adjust the laser settings accordingly

Automatic Registration

The camera can detect the position of previously cut features and align new cuts with them

Positioning

The camera can provide a real-time view of the material being cut, allowing the operator to accurately position the laser for precise cuts

Quality Control

The camera can monitor the cutting process and provide feedback to the operator or software to ensure that the cuts are being made correctly

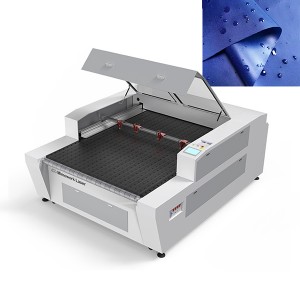

Recommended Fabric Laser Cutter

Conclusion

Overall, a camera recognition system can increase the accuracy and efficiency of laser cutting by providing real-time visual feedback and positioning information to the software and operator. To sum it up, it’s always a great choice to use CO2 laser machine to laser cut police patch and cordura patch.

Want to know more about our Laser Cutting Machine for your Cordura Patch?

Post time: May-08-2023