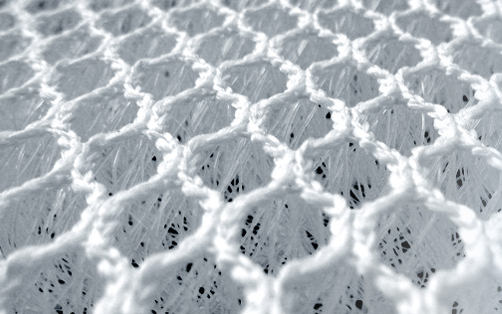

Lase Cut Mesh Fabric

What is Mesh Fabric?

Mesh fabric, also known as mesh material or mesh netting, is a type of textile characterized by its open and porous structure. It is created by interlacing or knitting yarns or fibers in a way that forms a series of evenly spaced and interconnected holes or openings. These openings give mesh fabric its distinctive breathable, lightweight, and transparent properties. In today’s article, we will talk about mesh fabric and how to laser cut mesh fabric.

Mesh fabric can be made from various materials such as cotton, polyester, nylon, or a combination of these fibers. The choice of material depends on the intended use and desired characteristics of the fabric. For example, polyester mesh is commonly used in athletic apparel and outdoor gear due to its moisture-wicking and quick-drying properties, while nylon mesh is often utilized in industrial applications where strength and durability are crucial.

Unique Features of Mesh Fabric

Great Breathability

Mesh fabric is well-known for its excellent breathability, allowing air to flow freely through the material. This property makes laser cut mesh fabric ideal for applications where ventilation and comfort are critical, such as in sportswear, outdoor equipment, and industrial filters. The open weave structure keeps the material lightweight while maintaining durability.

Lightweight

Another defining characteristic of mesh fabric is its light weight. Whether used in performance apparel or aerospace components, laser cut mesh offers the advantage of minimal weight without compromising strength. When combined with precise laser cutting technology, even the thinnest mesh materials can be shaped with smooth, sealed edges that prevent fraying.

Wide Applications

Furthermore, mesh fabric finds applications in a wide range of industries beyond fashion and sportswear. It is widely used in industrial settings for filtration purposes, as fencing or safety netting, in automotive upholstery, and even in medical devices such as surgical mesh for hernia repair.

Why Choose Laser Cutter for Cutting Mesh Fabric?

Using a fabric laser cutting machine to laser cut mesh fabric offers several advantages:

1. Precise and clean cuts:

Laser cutting machines are known for their high precision and accuracy. They can cut intricate and detailed patterns on mesh fabric with clean edges, resulting in a professional and finished look. The laser beam melts and seals the fabric as it cuts, preventing fraying and ensuring precise cuts every time.

2. Versatility:

A laser cutter can process a variety of mesh materials, including polyester, nylon, and metal-coated meshes. This versatility allows laser cut mesh fabric to be used across diverse industries — from breathable clothing panels to technical screens and industrial filters.

3. Minimal distortion:

Since laser cutting is a non-contact process, there’s no mechanical pressure on the mesh surface. This eliminates distortion and stretching, maintaining the material’s original structure — a key benefit for high-precision laser cut mesh components.

4. Increased efficiency and productivity:

Laser cutting machines are highly efficient and can cut through multiple layers of mesh fabric simultaneously. This saves time and increases productivity in the production process.

5. Flexibility in design:

Laser cutting machines allow for intricate and complex designs to be cut on mesh fabric. This flexibility opens up possibilities for creative and unique patterns, shapes, and cutouts, which may be challenging to achieve with traditional cutting methods.

6. Reduced waste:

With precise beam control, the cutting path is optimized to maximize material usage. This means less waste and higher yield per roll of mesh fabric, making laser cut mesh fabric a cost-effective and eco-friendly choice.

7. Ease of customization:

Laser cutting machines offer the ability to easily customize mesh fabric products. Whether it's adding logos, branding, or personalized designs, laser cutting can efficiently and accurately create customized patterns on mesh fabric.

8. Enhanced durability:

By sealing the edges during cutting, lasers prevent fraying and unraveling — common issues with traditional cutting. The result is a laser cut mesh fabric with long-lasting performance and durability, even under demanding conditions.

Learn more about how to laser cut mesh fabric

Recommended Laser Cutting Machine for Mesh

In summary, using a fabric laser cutting machine to laser cut mesh fabric provides precise cuts, versatility in material handling, minimal distortion, increased efficiency, flexibility in design, reduced waste, ease of customization, and enhanced durability. These advantages make fabric laser cutting a preferred method for cutting mesh fabric in various industries, including fashion, sports, industrial, and automotive.

Common Materials of laser cutting

Post time: May-17-2023