How to Laser Cut Woven Label?

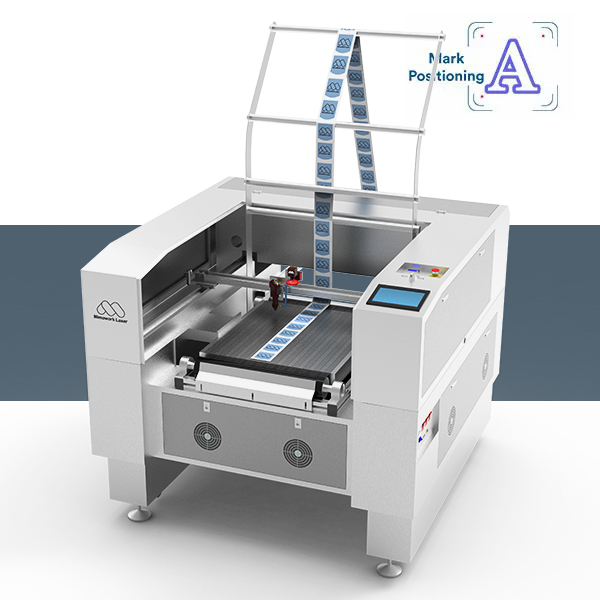

(Roll) woven label laser cutting machine

The woven label is made of polyester of different colors and woven together by the jacquard loom, which brings durability and vintage style. There are various types of woven labels, that are used in apparel and accessories, such as size labels, care labels, logo labels, and origin labels.

For cutting woven labels, the laser cutter is a popular and efficient cutting technology.

Laser cut woven label can seal the edge, realize precise cutting, and produce high-quality labels for high-end designers and small makers. Especially for roll woven labels, laser cutting provides a high automation feeding and cutting, that greatly enhances production efficiency.

In this article we will talk about how to laser cut woven label, and how to laser cut roll woven label. Follow me and dive into it.

How to Laser Cut Woven Label?

Step 1. Put the Woven Label

Put the roll woven label on the auto-feeder, and get the label through the pressure bar to the conveyor table. Ensure the label roll is flat, and align the woven label with the laser head to ensure accurate cutting.

Step 2. Import the Cutting File

The CCD camera recognizes the feature area of the woven label patterns, then you need to import the cutting file to match it with the feature area. After matching, the laser can automatically find and cut the pattern.

Step 3. Set the Laser Speed & Power

For general woven labels, laser power of 30W-50W is enough, and the speed you can set is 200mm/s-300mm/s. For the optimal laser parameters, you better consult your machine supplier, or make several tests to get.

Step 4. Start Laser Cutting Woven Label

After setting, start the laser, the laser head will cut the woven labels according to the cutting file. As the conveyor table moves, the laser head keeps cutting, until the roll is finished. The whole process is automatic, you just need to monitor it.

Step 5. Collect the finished pieces

Collect the cut pieces after laser cutting.

Have a idea of how to use laser to cut woven label, now you need to get a professional and reliable laser cutting machine for your roll woven label. The CO2 laser is compatible with most fabric including woven labels (we know it's made of polyester fabric).

1. Considering the features of roll woven label, we designed a special auto-feeder and conveyor system, that can help the feeding and cutting process run smoothly and automatically.

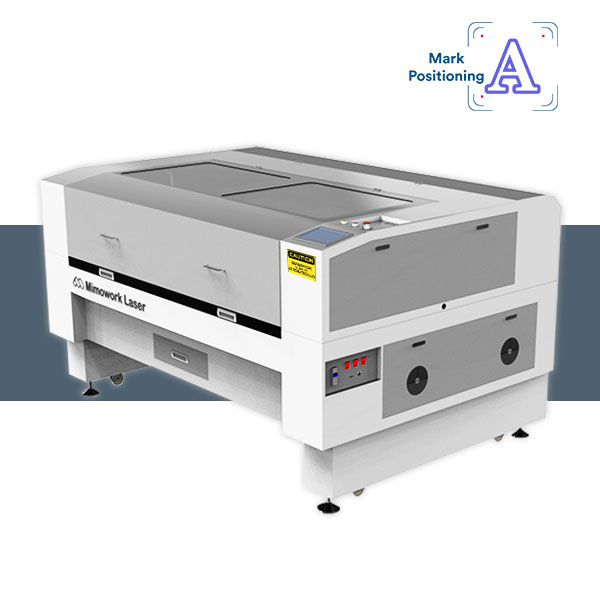

2. Besides for roll woven labels, we have the common laser cutting machine with a stationary working table, to complete the cutting for the label sheet.

Check out the below laser cutting machines, and select the one that suits your requirements.

Laser Cutting Machine for Woven Label

• Working Area: 400mm * 500mm (15.7” * 19.6”)

• Laser Power: 60W (optional)

• Max Cutting Speed: 400mm/s

• Cutting Precision: 0.5mm

• Software: CCD Camera Recognition System

• Working Area: 900mm * 500mm (35.4” * 19.6”)

• Laser Power: 50W/80W/100W

• Max Cutting Speed: 400mm/s

• Laser Tube: CO2 Glass Laser Tube or CO2 RF Metal Laser Tube

• Laser Software: CCD Camera Recognition System

What is more, if you have requirements for cutting embroidery patch, printed patch, or some fabric appliques, the laser cutting machine 130 is suitable for you. Check out the details, and upgrade your production with it!

Laser Cutting Machine for Embroidery Patch

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Laser Tube: CO2 Glass Laser Tube or CO2 RF Metal Laser Tube

• Laser Software: CCD Camera Recognition

Any Questions about Woven Label Laser Cutting Machine, Discuss with Our Laser Expert!

Advantages of Laser Cutting Woven Label

Different from manual cutting, laser cutting features heat treatment and non-contact cutting. That brings good enhancement to the quality of woven labels. And with the high automation, laser cutting woven label is more highly efficient, saving your labor cost, and increasing productivity. Make full use of these advantages of laser cutting to benefit your woven label production. It is an excellent choice!

★ High Precision

Laser cutting provides high cutting precision that can reach 0.5mm, allowing for intricate and complex designs without fraying. That brings great convenience for high-end designers.

★ Heat Treatment

Due to the heat processing, the laser cutter can seal the cutting edge while laser cutting, the process is fast and no need any manual intervention. You will get a clean and smooth edge without burr. And the sealed edge can be permanent to keep it from fraying.

★ Heat Automation

We already knew about the specially desiged auto-feeder and conveyor system, they bring automative feeding and conveying. Combined with laser cutting which is controlled by CNC system, the whole production can realize higher automation and less labor cost. Also, high automation makes handling mass production possible and time-saving.

★ Less Cost

Digital control system brings higher accuracy and less error rate. And the fine laser beam and auto nesting software can help improve the material utilization.

★ High Cutting Quality

Not only with high automation, but the laser cutting is also instructed by the CCD camera software, which means the laser head can position the patterns and cut them accurately. Any patterns, shapes, and designs are customized and the laser can perfectly complete.

★ Flexibility

The laser cutting machine is versatile for cutting labels, patches, stickers, tags, and tape. The cutting patterns can be customized into various shapes and sizes, and the laser is qualified for anything.

Woven labels are a popular choice for branding and product identification in various industries, especially in fashion and textiles. Here are some common types of woven labels:

1. Damask Woven Labels

Description: Made from polyester yarns, these labels have a high thread count, offering fine details and a soft finish.

Uses: Ideal for high-end clothing, accessories, and luxury items.

Advantages: Durable, soft, and can incorporate fine details.

2. Satin Woven Labels

Description: Made from satin threads, these labels have a shiny, smooth surface, giving a luxurious appearance.

Uses: Commonly used in lingerie, formal wear, and high-end fashion items.

Advantages: Smooth and shiny finish, luxurious feel.

3. Taffeta Woven Labels

Description: Made from polyester or cotton, these labels have a crisp, smooth texture and are often used for care labels.

Uses: Suitable for casual wear, sportswear, and as care and content labels.

Advantages: Cost-effective, durable, and suitable for detailed information.

4. High Definition Woven Labels

Description: These labels are produced using finer threads and higher-density weaving, allowing for intricate designs and small text.

Uses: Best for detailed logos, small text, and premium products.

Advantages: Extremely fine details, high-quality appearance.

5. Cotton Woven Labels

Description: Made from natural cotton fibers, these labels have a soft, organic feel.

Uses: Preferred for eco-friendly and sustainable products, baby clothes, and organic clothing lines.

Advantages: Eco-friendly, soft, and suitable for sensitive skin.

6. Recycled Woven Labels

Description: Made from recycled materials, these labels are an eco-friendly option.

Uses: Ideal for sustainable brands and eco-conscious consumers.

Advantages: Environmentally friendly, supports sustainability efforts.

Interested in Laser Cutting Labels, Patches, Stickers, Accessories, etc.

Related News

Cordura patches can be cut into various shapes and sizes, and can also be customized with designs or logos. The patch can be sewn onto the item to provide additional strength and protection against wear and tear.

Compared with regular woven label patches, Cordura patch is harder to cut since Cordura is a type of fabric that is known for its durability and resistance to abrasions, tears, and scuffs.

The majority of laser cut police patch is made of Cordura. It’s the sign of toughness.

Cutting the textile is a necessary process for making clothing, garment accessories, sports equipment, insulation materials, etc.

Increasing efficiency and reducing costs like labor, time, and energy consumption are most manufacturers' concerns.

We know you are looking for higher-performance textile cutting tools.

CNC textile cutting machines like CNC knife cutter and CNC textile laser cutter are favored due to their higher automation.

But for higher cutting quality,

Laser Textile Cutting is superior to other textile cutting tools.

Laser Cutting, as a subdivision of applications, has been developed and stands out in cutting and engraving fields. With excellent laser features, outstanding cutting performance, and automatic processing, laser cutting machines are replacing some traditional cutting tools. CO2 Laser is an increasingly popular processing method. The wavelength of 10.6μm is compatible with almost all non-metal materials and laminated metal. From daily fabric and leather, to industrial-used plastic, glass, and insulation, as well as craft materials like wood and acrylic, the laser cutting machine is capable of handling these and realizing excellent cutting effects.

Any Questions about How to Laser Cut Woven Label?

Post time: Aug-05-2024