Industrial Laser Cleaner: Editor's Pick (For Every Needs)

Looking for a Industrial Laser Cleaner?

Look no further as we hand-pick some of them out for you to choose from.

Whether you are looking for laser surface cleaning, a fiber laser cleaner, laser cleaning for metal or laser rust remover.

We got you covered.

From all applications to all possible needs, field-tested choices for you to browse from:

For Large Scale | Laser Surface Cleaning

3000W High Power Industrial Laser Cleaner

Well-suited for use in manufacturing, fabrication, and heavy industrial settings. Its robust construction ensures reliable performance even in demanding environments.

Laser Power: 3000W

Clean Speed: ≤70㎡/hour

Fiber Cable: 20M

Scanning Width: 10-200nm

Scanning Speed: 0-7000mm/s

Laser Source: Continuous Wave Fiber

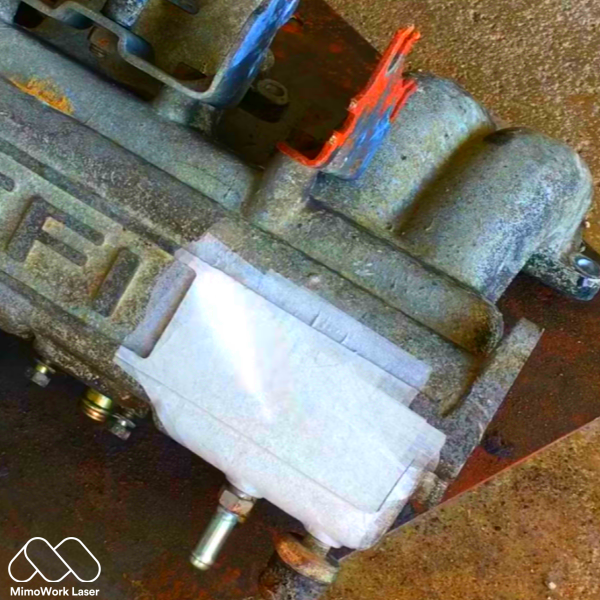

Laser Surface Cleaning of Heavy Rust

The 3000w high-power laser cleaner is a versatile tool with a wide range of applications. It is well-suited for large facility cleaning tasks such as removing contaminants from ships, automotive parts, pipes, and rail equipment.

The laser cleaner can also be used to clean rubber molds, composite dies, and metal dies, making it valuable for mold cleaning. For surface treatment applications, the laser cleaner can perform hydrophilic treatments as well as pre-weld and post-weld cleaning.

Beyond just cleaning, the laser can be used for paint removal, dust removal, grease removal, and rust removal on a variety of surfaces. Other unique applications include removing urban graffiti, cleaning printing rollers, and restoring building exterior walls.

Overall, this high-powered laser cleaner offers a flexible solution for industrial, commercial, and municipal cleaning and surface preparation needs.

Want to Know More about Industrial Laser Cleaner?

We Can Help!

For Detailed Cleaning | Pulsed Laser Cleaner

High Precision Pulsed Laser Cleaning for Delicate Cleaning

Pulsed fiber laser cleaners are particularly well-suited for cleaning delicate, sensitive, or thermally vulnerable surfaces, where the precise and controlled nature of the pulsed laser is essential for effective and damage-free cleaning.

Laser Power: 100-500W

Pulse Length Modulation: 10-350ns

Fiber Cable Length: 3-10m

Wavelength: 1064nm

Laser Source: Pulsed Fiber Laser

Small Heat Affected Zone (HAZ):

Pulsed lasers deliver energy in short, high-intensity bursts, typically in the nanosecond or picosecond range.

This rapid energy delivery results in a very small heat-affected zone on the target surface, minimizing the thermal impact and preventing damage to the underlying material.

In contrast, CW lasers have a larger HAZ due to the continuous heating of the surface, which can potentially alter or damage the substrate.

Minimal Temperature Rise:

The short pulse duration of pulsed lasers means the energy is delivered before the target surface has time to significantly heat up.

This prevents the target material from undergoing substantial temperature increases.

The rapid heating and cooling cycle of pulsed lasers allows for the efficient removal of contaminants without raising the overall temperature of the substrate.

Pulsed Laser Cleaning Paint

Reduced Thermal Stress:

The minimal temperature rise and small HAZ associated with pulsed lasers result in reduced thermal stress on the target surface.

This is important for cleaning materials that are susceptible to thermal deformation, cracking, or other structural changes.

The gentle nature of pulsed laser cleaning helps preserve the integrity and properties of the underlying substrate.

Related Video: Why Laser Cleaning is the Best

When comparing the leading industrial cleaning methods - sandblasting, dry ice cleaning, chemical cleaning, and laser cleaning - it's evident that each approach has its distinct advantages and drawbacks.

A thorough examination of various factors shows that laser cleaning emerges as a highly versatile, cost-effective, and user-friendly solution among the alternatives.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

For Grease & Paint | Laser Cleaning for Metal

Laser Cleaning for Metal with Handheld Flexibility in Mind

The ergonomically designed laser cleaning gun features a lightweight body and comfortable grip, making it easy to hold and maneuver. For accessing small nooks or uneven metal surfaces, the handheld operation provides greater flexibility and ease of use.

Laser Power: 100-3000W

Adjustable Laser Pulse Frequency: Up to 1000KHz

Fiber Cable Length: 3-20m

Wavelength: 1064nm, 1070nm

Support Various Languages

Handheld Laser Cleaning Rusty Metal

Handheld Laser Cleaner Gun

Linked to a fiber optic cable of a specific length, the handheld laser cleaner gun can move and rotate to adapt to the workpiece's position and angle, enhancing the mobility and flexibility of the cleaning process.

Digital Control System

The laser cleaning control system offers various cleaning modes by allowing the user to set different scanning shapes, cleaning speeds, pulse widths, and cleaning power. Additionally, the function of pre-storing laser parameters helps save time.

Related Video: What is Laser Cleaning?

Laser cleaning is a versatile and innovative cleaning method that is revolutionizing the way we approach cleaning and restoration tasks. Unlike traditional techniques like sandblasting, laser cleaning uses focused beams of light to safely and effectively remove a wide range of materials, including rust, from various surfaces.

In this 3-minute explanation, we'll dive into the details of how laser cleaning works and explore its benefits compared to other methods. Laser cleaning harnesses the power of light to selectively remove unwanted materials without damaging the underlying surface. This precise and controlled approach makes it ideal for delicate or sensitive applications where traditional methods may cause damage.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

For Rust | Laser Rust Remover

The Most Environmental Friendly & Cost-effective Method - Laser Rusr Remover

Effortlessly remove unsightly rust from metal surfaces with our advanced handheld laser cleaning system.

A fast, effective, and environmentally friendly solution for reviving metal equipment, tools, and structures.

Compact and easy to use. Experience the power of laser cleaning and reclaim the luster of your metal surfaces today.

Optional Multi-Mode

Flexible & Easy Operation

Support Various Languages

About Handheld Laser Rust Removal:

It is a modern technique that utilizes focused laser beams to remove rust from metal surfaces efficiently. This method offers several advantages over traditional rust removal methods, making it a popular choice for various applications.

Handheld laser rust removers find applications in various industries, including automotive, marine, construction, and restoration.

They are commonly used for rust removal on vehicles, machinery, tools, and historical or antique metal objects, where preserving the original surface is crucial.

Here are some Laser-Knowledge you Might be Interested in:

Laser Cleaning is the Future for Manufacturers and Workshop Owners

And the Future Starts with You!

Post time: Aug-15-2024