Laser Ablation is Better at Rust Cleaning (Here's Why)

Table of Content:

Intro:

As industrial cleaning demands continue to evolve, manufacturers and workshop owners are exploring a variety of cleaning methods to meet their needs.

Four of the top contenders are sandblasting, dry ice cleaning, chemical cleaning, and laser cleaning.

Each approach has its own unique strengths and considerations when it comes to cleaning effectiveness, cost, portability, and ease of use.

Cleaning Methods: Explained

Physically Abrasive or Non-Abrasive?

The core cleaning mechanisms can be divided into two main categories - physically abrasive and non-abrasive.

Sandblasting and dry ice cleaning fall under the physically abrasive methods.

They use high-velocity kinetic energy from blasted media, whether sand/grit or frozen CO2 pellets.

To mechanically remove contaminants from the target surface.

This brute force approach can be highly effective, but also carries a higher risk of surface damage if not used properly.

In contrast, chemical cleaning and laser cleaning are non-abrasive techniques.

Chemical cleaning relies on the reactive properties of liquid cleaning agents to dissolve and lift away contaminants.

Laser cleaning utilizes focused photonic energy to vaporize and remove unwanted materials without physical contact.

During Cleaning: Consumable Costs

The Ongoing Consumable Costs Associated with Each Method

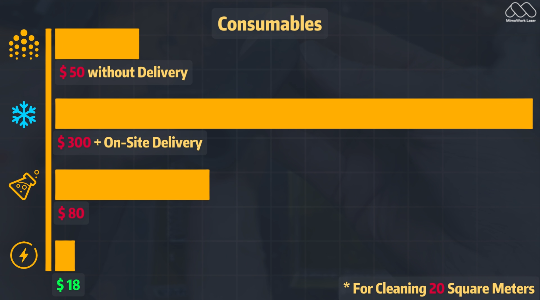

Sandblasting requires 20+ kg of abrasive media per 20 sq. m, costing roughly $50 without delivery.

Dry ice cleaning needs $300+ worth of industrial dry ice per 20 sq. m, or an upfront $6,000 investment in a portable dry ice maker.

Chemical cleaning uses 1-2 jugs (4 liters) of cleaning chemicals, at a cost of $80 per session.

Laser cleaning has the lowest consumable costs, only requiring electricity at around $18 per 20 sq. m.

Portability & Learning Curves

Between "Plug-and-Clean" to "An Hour of Setups"

Sandblasting and Dry ice cleaner setups tend to be more complex.

Involving multiple components and relying heavily on operator experience for optimal results.

Chemical cleaning and laser cleaners, on the other hand, are self-contained single-unit machines.

That are generally more "plug-and-play, point-and-clean" in nature, requiring less extensive training.

This difference in complexity translates to portability as well.

Chemical cleaning and laser cleaning systems can be easily transported to work sites.

While sandblasting and dry-ice cleaning equipment is more stationary and cumbersome to relocate.

Want to Make a Informed Purchase of a Laser Cleaner?

We can Help!

PPE Requirements for Safety

Labor-Intensive Process or Lighter Set of Requirements

Sandblasting is a labor-intensive process that requires extensive PPE.

Including a full-body suit, safety goggles, a face shield, a respirator, work gloves, and steel-toed boots.

Dry ice cleaning, while similar in setup, necessitates the use of insulated gloves to protect against the extreme cold.

Chemical cleaning also calls for the same level of PPE but with the addition of chemical-resistant gloves.

In contrast, laser cleaning stands out with a much lighter set of requirements.

Operators only need laser safety goggles, a laser safety face mask, a respirator, and long sleeves.

A significant reduction in the level of protection needed compared to the other methods.

Post Cleaning Considerations

It's All about Efficiency and Sustainability

After sandblasting, the containment media used must be thoroughly cleaned up, adding an extra step to the process.

Dry ice cleaning, on the other hand, typically requires no post-cleaning, making it a more streamlined option.

Chemical cleaning, while effective, necessitates the responsible disposal of the used cleaning solution.

Which can be a time-consuming and potentially hazardous task.

Laser cleaning, however, is a truly green process, as all you have to do is pack up the machine and leave.

No messy cleanup or waste disposal is required.

Why Laser Ablation is the Best

The Advantages of Laser Cleaning

Laser cleaning emerges as a highly portable option that only consumes electricity, making it a cost-effective choice.

Additionally, the learning curve for laser cleaning is relatively easy, allowing operators to quickly master the technique.

While the other methods have their own strengths.

The low environmental impact, simplified setup, and streamlined safety protocols of laser cleaning make it an increasingly attractive option.

For modern manufacturing and workshop environments.

Ultimately, the optimal choice will depend on the specific cleaning needs, budget constraints.

And operational priorities of each individual business or facility.

Related Video: What is Laser Cleaning & How it Works?

When evaluating the top industrial cleaning methods of sandblasting, dry ice cleaning, chemical cleaning, and laser cleaning.

It's clear that each approach offers a unique set of advantages and tradeoffs.

The comprehensive comparison across different factors reveals that:

Laser cleaning stands out as a highly versatile, cost-effective, and operator-friendly solution.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Machine Recommendations for Laser Ablation

Here are some Laser-Knowledge you Might be Interested in:

Laser Cleaning is the Future for Manufacturers and Workshop Owners

And the Future Starts with You!

Post time: Jul-26-2024