Laser Cleaning Aluminum: How to

Aluminum and aluminum alloys are widely used in rail transportation due to their high specific strength and corrosion resistance.

The surface of aluminum alloy easily reacts with air and forms a natural oxide film.

In this article, we will tell you everything you need to know about laser-cleaning aluminum.

Including why you should choose laser cleaning for aluminum, how to clean aluminum with pulsed laser cleaning, and the benefits of laser cleaning aluminum.

Table of Content:

Does Laser Cleaning Work on Aluminum?

In General Using Laser Cleaning Machine

Laser cleaning is an effective solution for cleaning aluminum surfaces in industrial applications.

It offers several advantages over traditional cleaning methods.

Such as chemical cleaning, mechanical polishing, electrolytic cleaning, and ultrasonic cleaning.

No Chemical Residues:

Laser cleaning is a dry, non-contact process, which means there are no chemical residues left behind.

This is crucial for railway and aircraft industries.

Improved Surface Finish:

Laser cleaning can enhance the surface finish of aluminum by removing surface imperfections, oxidation, and other unwanted materials.

This results in a clean, uniform appearance.

Environmental Friendliness:

Laser cleaning is an environmentally friendly process, as it does not require the use of hazardous chemicals or solvents, which can be harmful to the environment.

Improved Adhesion:

The clean, contaminant-free surface achieved through laser cleaning can enhance the adhesion of coatings, paints, or other surface treatments applied to the aluminum.

Damage & Risk-Free:

Laser cleaning allows for highly targeted and precise removal of unwanted materials without damaging the underlying aluminum surface.

The laser can be precisely controlled to remove only the desired contaminants.

Versatility:

Laser cleaning can be used on a wide range of aluminum parts and components.

From small intricate parts to large-scale structures, making it a versatile cleaning solution.

Can you Laser on Aluminum?

Yes, You Can Use Lasers on Aluminum.

Laser technologies are effective for cutting, engraving, and cleaning aluminum surfaces. Here are some common applications:

For Laser Cutting & Laser Engraving:

Lasers provide precise cuts for complex shapes and fast processing compared to traditional methods—high-resolution engraving for logos, designs, or markings. Engravings are permanent and resistant to wear.

For Laser Cleaning:

Effectively removes contaminants like rust and paint without damaging the aluminum, with no chemicals needed.

The effectiveness can depend on the thickness of the aluminum. Different types of lasers (CO2, fiber) are suited for various applications. Lasers can be effectively used on aluminum for multiple purposes, making them a versatile tool in manufacturing and maintenance.

What is the Best Solution for Cleaning Aluminum?

For Industrial or Heavy-duty Cleaning, Laser CLeaning is the Way to go.

Handheld Laser Cleaning Machines can effectively remove contaminants without damaging the aluminum. In addition to the benefits mentioned above, laser cleaning also offers unique advantages for welding applications:

Greatly Improved Weld Quality:

Laser cleaning removes surface contaminants, oxides, and impurities that can negatively impact weld quality and strength.

By providing a clean, contaminant-free surface, laser cleaning helps ensure better fusion, stronger weld joints, and reduced risk of defects.

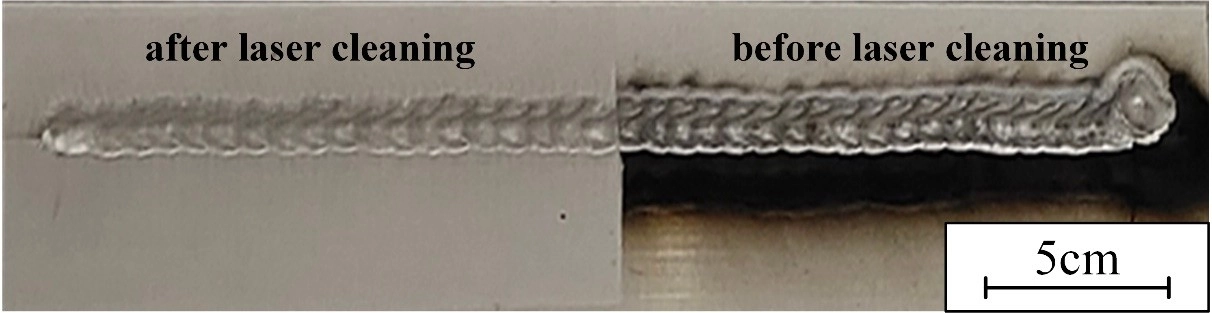

The weld formation before and after laser cleaning of black ash on aluminum.

Increased Weld Consistency:

Laser cleaning provides a consistent, repeatable surface preparation, resulting in more consistent weld quality and properties across multiple welds.

This consistency is crucial for manufacturing processes, quality control, and ensuring reliable performance of the welded assembly.

Reduced Weld Porosity:

Laser cleaning effectively removes surface contaminants and oxides that can lead to the formation of weld porosity.

Reducing weld porosity improves the mechanical properties and integrity of the weld joint.

Improved Weldability:

The clean surface left by laser cleaning can enhance the weldability of aluminum, making it easier to achieve sound, defect-free welds.

This is particularly beneficial when welding thinner aluminum materials or working with challenging aluminum alloys.

Enhanced Weld Appearance:

The clean, uniform surface left by laser cleaning results in a more aesthetically pleasing weld appearance.

This is particularly important for applications where the weld is visible or needs to meet stringent aesthetic requirements.

If you are under a home-use application, some Soap Water or Commercial Aluminum Cleaner Solutions may also work fine, remember to Steer clear of abrasive pads or harsh chemicals that can scratch or corrode aluminum. Always test any cleaning solution on a small, inconspicuous area first.

Laser Cleaning Aluminum can be Tricky

We can Help!

What are the Disadvantages of Laser Cleaning?

Initial Cost and Dealing with Extra Thick Coatings, that's about it really.

The upfront cost of purchasing a handheld laser cleaning machine can be significant (Compared to Traditional Cleaning Methods). However, since Laser Cleaning ONLY needs electricity, the Operational Cost is way cheaper.

Laser cleaning may struggle with VERY THICK layers of rust. However, a sufficient power output and continuous wave laser cleaners should solve this problem.

For Pre-welding Cleaning on Aluminum, Laser Fits the Shoes Perfectly

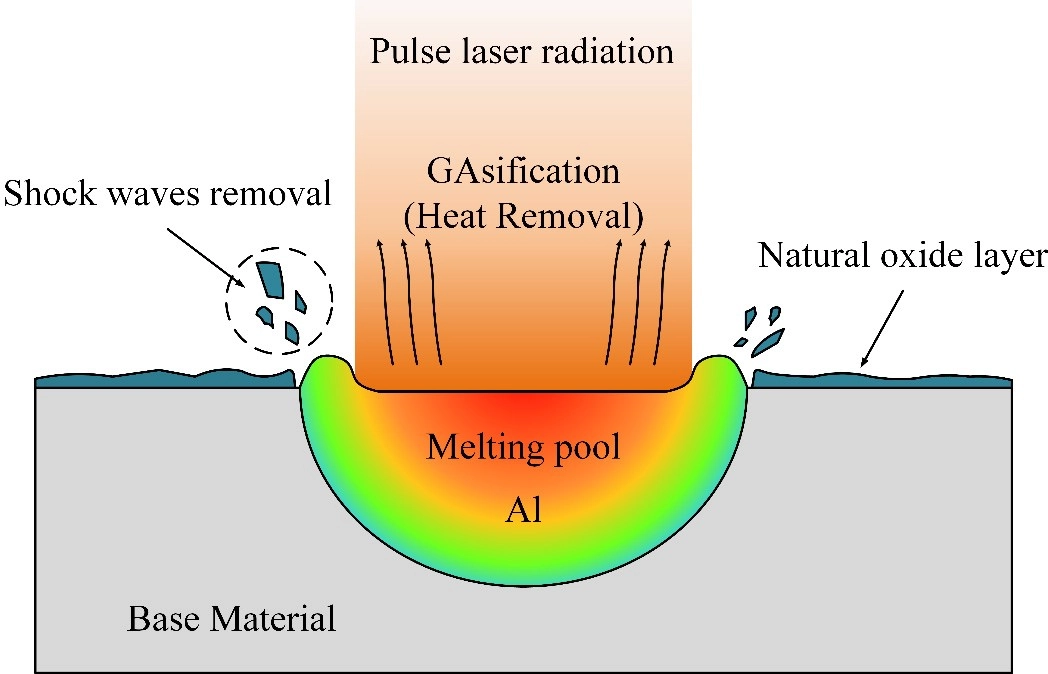

Laser cleaning is a powerful technique for preparing surfaces before welding, especially when dealing with contaminants like rust, oil, and grease.

These contaminants can severely compromise the quality of a weld, leading to issues such as porosity and poor mechanical properties.

Contaminants on the surface of the aluminum can prevent proper fusion between the base metal and the filler material during welding.

This can result in defects like porosity, cracks, and inclusions, which can significantly weaken the weld.

Removing these contaminants is crucial to ensure a high-quality, robust weld.

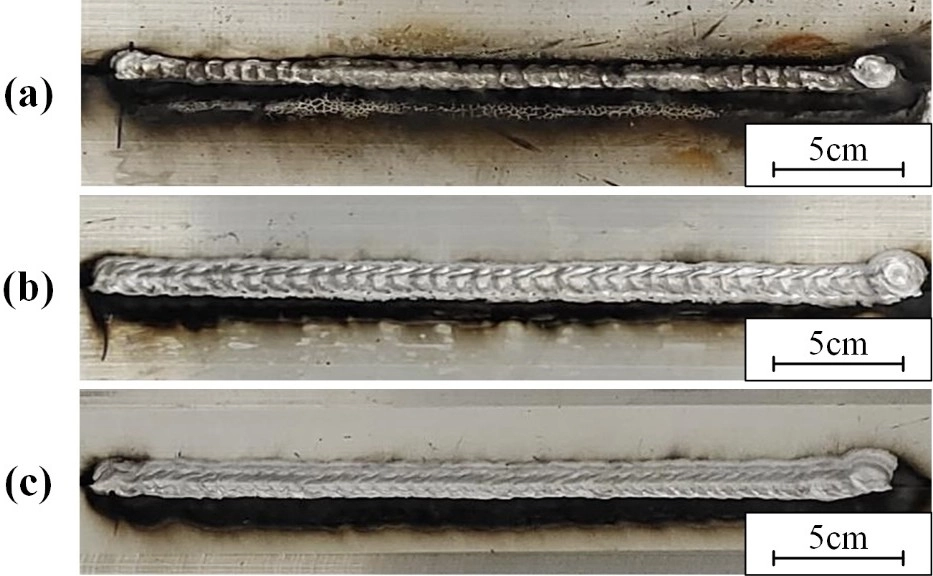

As a study has shown, laser cleaning can effectively remove dirt and suppress weld porosities on aluminum surfaces with oil and water contamination.

The study found that the porosity was reduced from 28.672% and 2.702% to 0.091%, respectively, after laser cleaning.

Additionally, the black ash around the weld seam can be effectively removed by post-weld laser cleaning, and this slightly improves the elongation of the weld.

The weld formation on sample with: (a) oil; (b) water; (c) laser cleaning.

What Should you NOT Clean Aluminum with?

Ruining Aluminum is Actually Easier than you Think

Want to Ruin your Aluminum with Cleaning? Use these:

Abrasive Cleaners to scratch and dull the surface of the aluminum.

Acidic or Alkaline Solutions to corrode and discolor aluminum.

Bleach causes pitting and discoloration on aluminum surfaces.

Steel Wool or Scouring Pads leave scratches and contribute to corrosion.

High-Pressure Washers damage seals and fittings, and may not effectively clean delicate areas.

Harsh Solvents strips protective coatings and damage the surface.

Oven Cleaners are typically caustic and can harm aluminum surfaces.

Want to Clean Aluminum the RIGHT Way? Try out Laser Cleaning

Aluminum has unique characteristics that make welding and cleaning it more complicated compared to other metals like stainless steel.

Aluminum is a highly reflective material, which can make it challenging to absorb laser energy during the cleaning process.

Additionally, the oxide layer that forms on the surface of aluminum can be difficult to remove, further complicating the cleaning process.

As for the best settings for laser cleaning aluminum.

It's important to note that the settings used in the referenced paper (150W, 100Hz, and 0.8m/min cleaning speed).

Are specific to the 6005A-T6 aluminum alloy they studied and the equipment they used.

These settings can serve as a reference point, but they may need to be adjusted for your specific application and equipment.

In summary, laser cleaning is an effective technique for preparing aluminum surfaces before welding.

As it can remove contaminants and improve weld quality.

However, the unique characteristics of aluminum require careful consideration.

When determining the optimal laser cleaning settings for your specific application.

The information provided in this Article is based on publicly available data and research.

I do not claim ownership over any of the data or research used.

This is for informational purposes only.

Pulsed Laser for Cleaning Aluminum

Want to Pulse Laser Cleaning Aluminum? Look no Further!

Pulsed Laser Cleaner

For Laser Cleaning Aluminum (100W, 200W, 300W, 500W)

Harness the power of pulsed fiber laser technology to take your cleaning game to new heights.

Our cutting-edge pulsed laser cleaner offers unparalleled precision and efficiency.

Without compromising the integrity of your delicate surfaces.

The pulsed laser output targets contaminants with laser-sharp accuracy.

Ensuring a spotless finish without heat-related damage.

The non-continuous laser output and high peak power make this cleaner a true energy-saver.

Optimizing your resources for maximum cost-effectiveness.

From rust removal and paint stripping to oxide elimination and contaminant removal.

Enjoy premium stability and reliability with our state-of-the-art fiber laser technology, Designed to withstand the test of time.

Tailor the cleaning process to your specific needs with the flexible pulsed laser settings, Ensuring a perfect result every time.

Experience the freedom to maneuver and adjust the cleaning positions and angles with our user-friendly, ergonomic design.

Related Video: Why Laser Cleaning is the Best

When evaluating the top industrial cleaning methods of sandblasting, dry ice cleaning, chemical cleaning, and laser cleaning.

It's clear that each approach offers a unique set of advantages and tradeoffs.

The comprehensive comparison across different factors reveals that:

Laser cleaning stands out as a highly versatile, cost-effective, and operator-friendly solution.

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Machine Recommendations for Laser Cleaning Aluminum

Laser Cleaning is the Future for Manufacturers and Workshop Owners

And the Future Starts with You!

Post time: Aug-13-2024