Laser Cleaning for Wood:

The Ultimate Guide to Surface Restoration Techniques

Introduction:

Wood is a very common material in our daily life. It is especially widely used in construction, decoration, furniture and other fields. Long-term storage will accumulate dust, dirt, paint, coatings and other debris on the surface. Cleaning it up is relatively troublesome, labor-intensive and time-consuming.

Have you ever wondered if there is a more efficient way to clean wood surfaces?

The development of laser technology has provided an innovative solution for cleaning wood.

This article explores the effectiveness and efficiency of laser wood cleaning and takes you deeper into this technology.

What is Laser Wood Cleaning?

Laser wood cleaning is an advanced technique that uses high-energy laser beams to remove contaminants, stains, paint, or other coatings from the surface of wood. By interacting with the surface, the laser energy heats and vaporizes the unwanted material, effectively cleaning the wood without causing damage. This innovative technique offers a non-invasive, chemical-free, and highly effective solution for restoring the natural beauty of wood.

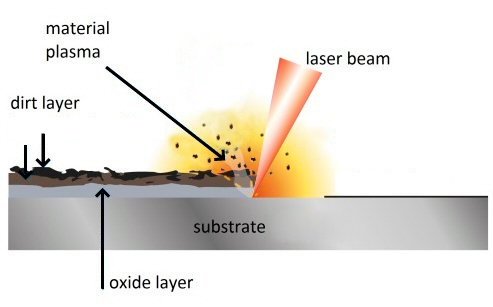

Principle of Laser Cleaning

Advantages

· Eco-friendly: Eliminates the need for harsh chemicals and abrasive materials.

· Precision: Targets stains directly without damaging the surrounding wood.

· Efficiency: Quickly removes stains, saving time and effort.

· Non-invasive: Preserves the wood’s original texture and color.

· Cost-effective: Reduces the need for costly refinishing or sanding.

Laser Cleaning Wood

Limitations

Limited Scope of Application

Heat Accumulation

Skill Requirements

While laser cleaning is highly effective for removing surface contaminants, paints, and oils, it may not be suitable for large-scale cleaning of heavily contaminated surfaces or deep-seated stains. For example, laser cleaning may not be the best choice for extensively dirty wood surfaces.

Prolonged use of the laser on the same area can lead to heat accumulation, which, if not controlled, can cause wood charring or even ignition. Although most laser cleaning devices are equipped with cooling systems, care must be taken when using them on sensitive wood surfaces.

Operating a laser cleaning device requires a certain level of technical knowledge and training. Improper use can result in suboptimal cleaning or damage to the wood.

Key Applications of Laser Wood Cleaning

Laser cleaner for wood offer versatility for a variety of restoration needs.

1. Furniture Restoration

Laser cleaner for wood excels in furniture restoration.

It effectively removes stains, old finishes, and coatings while preserving the natural grain of the wood.

Whether it’s antique or modern furniture, laser cleaning can restore the wood surface without causing damage.

This makes it an ideal choice for high-value items.

Laser Cleaning Applications in

Furniture Restoration

Laser Cleaning Applications in

Building and Decorative Restoration

2. Building and Decorative Restoration

For architectural woodwork or decorative panels, laser wood cleaners can precisely remove weathering, dirt, or old varnish.

This restores the appearance without causing damage.

This makes laser cleaning suitable for restoring architectural details and fine woodwork.

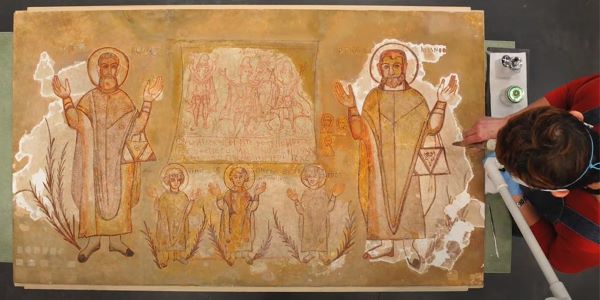

3. Art and Antique Restoration

Laser cleaners are often used in restoring wooden artifacts, sculptures, or antique items.

The precise, controlled cleaning allows conservators to gently remove dirt and aged coatings while keeping the original details intact.

Which is crucial for preserving historical value.

Laser Cleaning Applications in

Art and Antique Restoration

Comparing Laser Wood Cleaners with Traditional Methods

While wood laser cleaner provide many benefits, it’s essential to understand how they stack up against other methods.

Comparison with Chemical Cleaning

Chemical cleaning can be effective but often produces hazardous waste and requires extensive safety precautions.

Laser cleaning is chemical-free, eco-friendly, and safer for operators. Additionally, lasers avoid the risk of chemical absorption into the wood, which can cause long-term damage.

Comparison with Sanding and Scraping

Sanding and scraping are common but can be labor-intensive and abrasive to the wood. These methods may lead to uneven surfaces or even gouges.

Laser cleaning, offers a consistent, non-abrasive solution that preserves the wood surface’s natural integrity and reduces the risk of accidental damage.

By comparing laser wood cleaners to traditional methods, you can make a more informed decision and choose the method that is best for your specific application.

Want to know more about laser cleaning machines?

How Do We Choose a Wood Laser Cleaner?

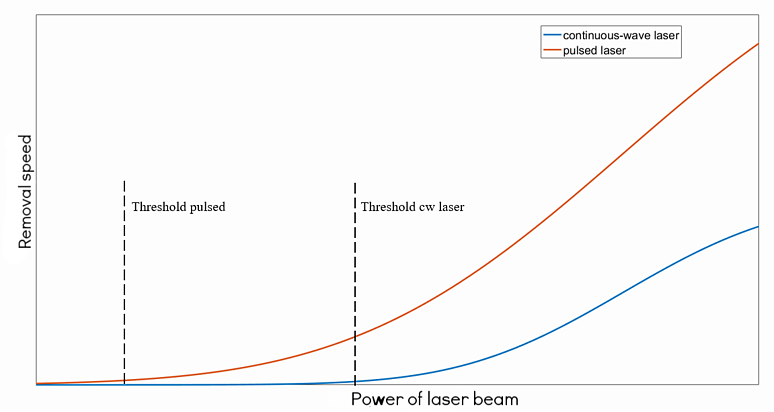

1. Power of Laser

The power of a laser affects its ability to remove different types of coatings. Higher-powered lasers are more effective for thicker, harder coatings. Lower-powered lasers may be adequate for removing thinner, more delicate coatings.

· Low Power Cleaner (20W - 100W): Suitable for light rust removal, where speed is not critical and batch size is small. They offer cost savings.

· Medium Power Cleaner (200W - 300W): Ideal for removing moderate rust or grease but require effective cooling due to higher heat generation; otherwise, both the machine and the product may be affected.

· High Power Cleaner (350W - ): Designed for heavy-duty metals in large production or repair units, though their high power results in higher prices.

Relationship between Laser Beam Power and Removal Speed

2. Size and Portability

If you need to move easily between locations, a portable system, such as a backpack or handheld, may be a better fit for you.

If your project requires constant work in a workshop, you may want to choose a larger, more stationary unit.

3. Adjustability

Look for a system that offers adjustable power, speed, and focus settings.

This versatility allows you to fine-tune the laser for different types of wood and coatings.

4. Safety Features

Make sure the laser system includes the necessary safety features to protect the operator. Include goggles to protect your eyes from laser exposure.

You need to know: How to choose a laser cleaning machine

Pulsed Fiber Laser Cleaner with a Higher Cleaning Quality

The pulsed fiber laser featuring high precision and no heat affection area usually can reach an excellent cleaning effect even if under a low power supply.

Due to the noncontinuous laser output and high peak laser power, the pulsed laser cleaner is more energy-saving and suitable for fine parts cleaning.

The fiber laser source has premium stability and reliability, with the adjustable pulsed laser, is flexible and serviceable in rust removal, paint removal, stripping coating, and eliminating oxide and other contaminants.

Don't know which type of laser cleaning machine to choose?

Future Trends (2024 Data Insights)

Cultural Heritage Preservation: Laser cleaning is increasingly used for restoring delicate wooden artifacts and historical structures, offering non-abrasive solutions for soot and biological growth removal.

AI Integration: Smart laser systems with AI and real-time feedback optimize precision, adapting to wood type and contamination for non-invasive cleaning.

Hybrid Lasers: Multi-wavelength systems (UV, infrared) enable tailored cleaning for specific contaminants like paint or mold, enhancing versatility.

Sustainability Focus: Aligning with global eco-friendly goals, laser cleaning eliminates chemical solvents and supports circular economy practices.

Composite Wood Applications: Laser cleaning is being adapted for engineered wood products, treating adhesives and coatings without damaging structural integrity.

Summarize

Laser stripping wood has many benefits. It is precise, quick, and good for the environment. It has changed industries like car making and woodworking. Lasers are cleaner and faster than old ways. As technology gets better, lasers will be used more in woodworking. Many people see its value and think more will use it soon. Using lasers boosts work speed and helps the planet. Trying out this new tool can make woodwork better and greener, leading to a smarter future.

Things You Need to Know about: Laser Cleaning Machine

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Feb-07-2025