Laser Cutting Paper:

Illuminating Boundless Creativity and Precision

▶ Introduction:

Laser cutting of paper takes creativity and precision to new heights. With laser technology, intricate designs, complex patterns, and delicate shapes can be effortlessly cut with unmatched accuracy. Whether for art, invitations, packaging, or decoration, laser cutting unlocks endless possibilities. Say goodbye to laborious manual cutting and embrace the clean, crisp edges achieved through laser cutting. Experience the versatility and efficiency of this cutting-edge technique, bringing your paper projects to life with astonishing precision and intricate detail. Elevate your paper crafts with the precision of laser cutting.

Key Principles and Advantages of Laser Cutting Paper:

▶ Laser Paper Cutting:

Compared to traditional manual methods, laser cutting offers greater speed, reduced labor costs, eliminates the need for secondary mold creation, and provides unlimited design possibilities without restrictions on shapes. Laser cutting offers precise and complex pattern processing, making it a one-stop solution without the need for secondary processing.

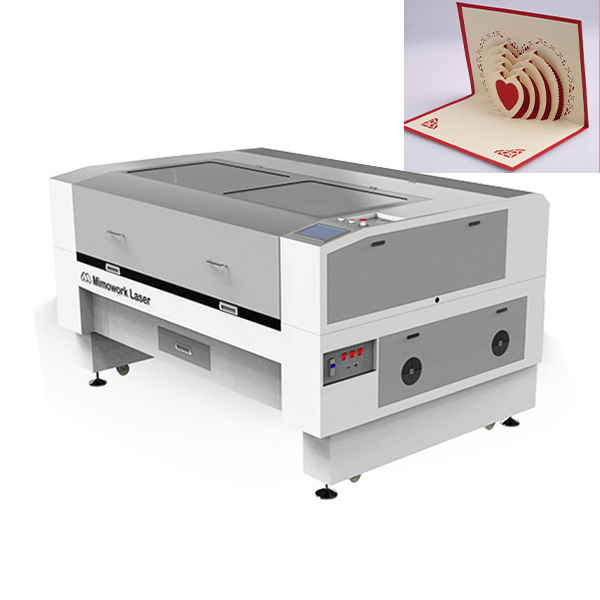

Laser paper cutting employs high-energy density laser beams to cleanly cut and create intricate hollow patterns on paper. By transferring desired graphics to a computer, achieving the desired effect becomes effortless. Laser cutting and engraving machines, with their unique design and high-performance configuration, significantly enhance work efficiency, making them essential equipment in the paper product industry.

Video Display | how to laser cut and engrave paper

what you can learn from this video:

In this video, you will delve into the setup of CO2 laser engraving and laser cutting of paperboard, uncovering its remarkable features and capabilities. Renowned for its high speed and precision, this laser marking machine delivers exquisite laser-engraved paperboard effects and offers flexibility in cutting paper of various shapes. Its user-friendly operation makes it accessible even for beginners, while the automated laser cutting and engraving functions make the entire process simple and user-friendly.

▶Distinct Advantages of Laser Cutting Paper Compared to Ink Printing or Die Cutting:

1.Flexible working environment suitable for offices, stores, or print shops.

2. Clean and safe technology requiring only lens cleaning.

3. Economical with low maintenance costs, no consumables, and no need for molds.

4. Accurate processing of intricate designs.

5. Multifunctionality:surface marking, micro-perforation, cutting, scoring, patterns, text, logos, and more in one process.

6.Environmentally friendly with no chemical additives.

7.Flexible production for single samples or small batch processing.

8. Plug and play with no further processing required.

▶Suitable Applications:

Personalized business cards, greeting cards, scrapbooks, promotional displays, packaging, handicrafts, covers and journals, bookmarks, and various paper products, enhancing product quality.

Laser cutting machines can quickly cut various types of paper without adverse effects based on paper thickness, including paper cutting, paper boxes, and various paper products. Laser cutting paper holds tremendous potential due to its mold-free nature, allowing for any cutting style, thus providing high flexibility. Moreover, laser paper cutting machines offer exceptional accuracy, one of their significant advantages, with no external forces compressing or causing deformation during cutting.

Video Glance | paper cutting

Key Features of a Reliable Laser Cutting Machine:

1. Smooth cutting surface with no burrs.

2. Thin cutting seams, typically ranging from 0.01 to 0.20 centimeters.

3. Suitable for processing large-sized products, avoiding the high cost of mold manufacturing.

4. Minimal thermal deformation due to the concentrated energy and high-speed nature of laser cutting.

5. Ideal for rapid prototyping, shortening the product development cycle.

6. Material-saving capabilities through computer programming, maximizing material utilization.

▶Tips for Laser Paper Cutting:

- Use a lens with the shortest focal length for finer laser spot and increased precision.

- To prevent paper overheating, use at least 50% of the laser's maximum speed.

- Reflective laser beams hitting the metal table during cutting can leave marks on the backside of the paper, so it's recommended to use a Honeycomb Laser Bed or a Knife Strip Table.

- Laser cutting produces smoke and dust that may settle and contaminate the paper, so it's advisable to use a fume extractor.

Video Guide | Test Before You Multilayer Laser Cutting

what you can learn from this video:

The video takes multilayer laser cutting paper for example, challenging the limit of CO2 laser cutting machine and showing the excellent cutting quality when galvo laser engrave paper. how many layers can a laser cut a piece of paper? As the test shown, it is possible from laser cutting 2 layers of paper to laser cutting 10 layers of paper, but 10 layers may be at risk of paper being ignited. How about laser cutting 2 layers fabric? How about laser cutting sandwich composite fabric? We test laser cutting Velcro, 2 layers of fabric and laser cutting 3 layers fabric.

Want to Get a Head Start?

What About These Great Options?

Want to get Started with a Laser Cutter& Engraver Right Away?

Contact Us for Inquire to get Started Right Away!

▶ About Us - MimoWork Laser

We Don't Settle for Mediocre Results

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industry.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

MimoWork has been committed to the creation and upgrade of laser production and developed dozens of advanced laser technology to further improve clients' production capacity as well as great efficiency. Gaining many laser technology patents, we are always concentrating on the quality and safety of laser machine systems to ensure consistent and reliable processing production. The laser machine quality is certificated by CE and FDA.

MimoWork Laser System can laser cut Acrylic and laser engrave Acrylic, which allows you to launch new products for a wide variety of industries. Unlike milling cutters, engraving as a decorative element can be achieved within seconds by using a laser engraver. It also gives you the opportunity to take orders as small as one single unit customized product, and as large as thousands of rapid productions in batches, all within affordable investing prices.

Get More Ideas from Our YouTube Channel

Post time: Jul-18-2023