Laser Textile Cutting: Precision and Efficiency

Introduction:

Key Things to Know Before Diving In

Laser cutting textile is a highly precise and efficient method for crafting various products and designs. This guide explores the basics, benefits, challenges, and practical techniques of laser textile cutting.

Introduction

▶ What is Laser Textile Cutting?

It uses a focused laser beam to cut through textile materials, guided by computer controls for accuracy. The heat from the laser instantly melts or vaporizes the material, resulting in clean cuts.

Overall, laser cutting textile is a powerful technique offering precision and creativity for high-quality products.

Laser Cut Leather

Key Benefits

▶ Clean & Precise Cuts

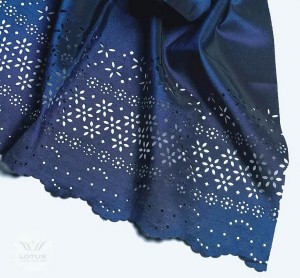

Laser cutting produces clean, exact cuts with minimal heat-affected zone and no fraying, thanks to the laser heat sealing synthetic fabric edges.

▶ Reduced Waste & Cost-Effective

By precisely cutting complex shapes, material waste is minimized, making it suitable for producing complex designs at lower costs.

Laser Cut Design

▶ High Speed & Efficiency

The process is fast, enabling quick textile production, and some machines support automatic continuous cutting for increased efficiency.

▶Versatility & Precision

Laser cutting can cut, engrave, and create intricate designs on various fabrics without causing damage, meeting the unique design needs of designers and manufacturers.

▶ No Physical Contact & Customization

The contactless process avoids fabric distortion and tool wear, ensuring consistent quality, and laser tables and systems can be customized to fit various material sizes and types.

Any Ideas About Laser Textile Cutting, Welcome To Discuss With Us!

Applications

Automotive:Air Bag,Automotive Interior,Alcantara Car Seat

Fashion & Apparel:Apparel Accessories,Footwear,Functional Clothing,Leather Jewelry,Bulletproof Vest

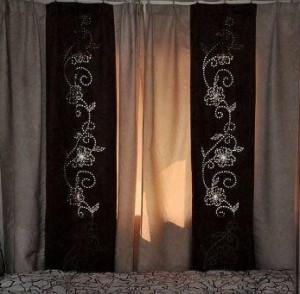

Laser Cut Curtain

Laser Cut Bag

Home & Daily Use:Home Textiles,Cornhole Bags,Fabric Duct,Plush Toy,Sandpaper

Industrial & Special Use:Insulation Materials,Outdoor Equipment,Perforated Cloth,Filter Cloth,Gasket (felt),Sublimation Fabrics

Detailed Process Steps

Preparation: Choose suitable, clean, and wrinkle-free fabric. Place roll fabrics on the auto-feeder.

Setting Up: Select appropriate laser power, speed, and frequency based on the fabric type and thickness. Ensure the built-in software is ready for precise control.

Fabric Cutting: The auto-feeder transports the fabric to the conveyor table. The laser head, controlled by the software, follows the cutting file to cut the fabric accurately.

Post-processing: Inspect and finish the cut fabric to ensure quality, addressing any necessary trimming or sealing of edges.

▶ Added Value from Mimo Laser Cutter

Efficiency and Speed: There are multiple replaceable laser heads and an automatic feeding system to increase cutting and engraving speed while ensuring smooth, continuous operation.

Material Handling and Waste Reduction: The system handles heavyweight and multi-layer fabrics with precision, while nesting software optimizes layout to minimize waste.

Precision and Customization: A camera recognition system ensures precise contour cutting of printed fabrics, and the laser tables can be customized to fit various material sizes and types.

Ease of Use and Functionality: User-friendly MimoCUT software simplifies the process with optimal cutting paths, and an extension table provides a convenient collection area during cutting.

Stability and Safety: The MimoWork vacuum table keeps fabric flat during cutting, ensuring stability and safety by preventing fires through proper laser head height adjustment and exhaust systems.

General Tips for Laser Textile Cutting

1. Material Compatibility: Ensure the fabric suits laser cutting.

2. Laser Power: Match the power to the fabric's thickness and type.

3. Machine Size: Choose a machine with a suitable working area for the fabric size.

4. Speed and Power Testing: Test low power and high speed settings on spare fabric to find optimal parameters.

5. Proper Exhaust: Ensure adequate ventilation to remove smoke and particles, optimizing cutting conditions.

▶ More Information About Laser Textile Cutting

Less Time, More Profit! Upgrade Fabric Cutting

The CO2 laser cutter with extension table empower the fabric laser cutting with a higher efficiency and output. The video introduces a 1610 fabric laser cutter that can realize continuous cutting fabric (roll fabric laser cutting) while you can collect the finishing on the extension table. That is greatly time-saving!

To upgrade your textile laser cutter? Want a longer laser bed but no more budget? The two heads laser cutter with an extension table will be a great help. Besides higher efficiency, the industrial fabric laser cutter can hold and cut ultra-long fabric such as pattern longer than working table.

Laser Textile Cutting FAQs

1. Can you laser cut textile?

Yes.You can laser cut a variety of textiles, including natural and synthetic materials, with a laser cutter, and the heat of the laser can even seal the edges of some fabrics, preventing fraying.

A wide variety of textiles are suitable for laser cutting such as cotton, silk, velvet, nylon, polyester or cordura.

2. How are lasers used in textiles?

Most textile cutting tends to be done with a CO2 laser, a gas laser that creates infrared light. This is a different laser than those used to cut hard materials like wood or metal.

A machine guides the laser, which then cuts pieces of fabric by melting or vaporizing it along lines corresponding to the design.

3. How does laser cutting fabric work?

The fabric laser cutting process involves directing a concentrated laser beam onto the fabric, which heats and vaporizes the material along the desired cutting path. The laser cutting machine uses a controlled motion system to move the laser head, ensuring accuracy and consistency.

4. Which materials are not suitable for laser cutting and engraving?

Leather and artificial leather that contains chromium (VI),Carbon fibers (Carbon),Polyvinyl chloride (PVC),Polyvinyl butyrale (PVB),Polytetrafluoroethylenes (PTFE /Teflon),Beryllium oxide.

5. How does machine ensure the accuracy of cutting?

A CCD camera is installed beside the laser head to locate the workpiece via registration marks at the cutting start.

Thus, the laser can visually scan printed, woven, and embroidered fiducial marks, along with other high-contrast contours, to identify the exact position and size of the fabric workpieces for precise cutting.

Laser Cut Dress

Recommended Machine For Laser Textile Cutting

To achieve the best results when cutting polyester, choosing the right laser cutting machine is crucial. MimoWork Laser offers a range of machines that are ideal for laser engraved wood gifts, including:

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm (62.9” * 39.3 ”)

• Laser Power: 150W / 300W/ 450W

• Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

• Laser Power: 150W / 300W/ 450W

• Working Area (W *L): 1600mm * 3000mm (62.9’’ * 118’’)

Conclusion

Laser cutting textile is a precise and efficient method for crafting various products and designs.It uses a focused laser beam guided by computer controls to cut through textile materials, resulting in clean cuts.This technique is widely used in accessories, apparel, home goods, medical textiles, home decor, and specialty fabrics.The advantages of laser textile cutting include clean and precise cuts, no fraying, high speed, reduced waste, versatility, precision, efficiency, cost-effectiveness, customization, and no physical contact.

When laser cutting textiles, consider material compatibility, laser power, machine size, speed and power testing, and proper exhaust.The process involves preparation, setting up, fabric cutting, and post-processing.FAQs about laser cutting textiles include questions about suitable materials, the laser cutting process, materials not suitable for laser cutting, and how machines ensure cutting accuracy.

Related Articles

Any Questions About Laser Textile Cutting?

Post time: Mar-18-2025