Laser Welding Aluminum Using a Laser Welder

Laser Welding Aluminum - Changing the Industries by Storm

Laser welding aluminum—sounds like something from a high-tech sci-fi movie, doesn’t it?

Well, in reality, it’s not just for futuristic robots or aerospace engineering.

It's actually a game-changer in industries where precision and strength matter, and over the years, I've had my fair share of hands-on experience with it.

Let me walk you through what I’ve learned and how laser welding aluminum can actually be a bit of a revelation.

Table of Content:

The Basics of Laser Welding Aluminum

It’s a Precise, Efficient Method for Welding

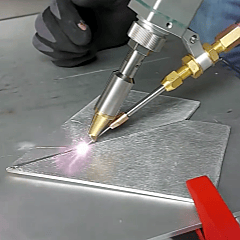

At its core, laser welding aluminum uses a focused laser beam to melt and fuse pieces of aluminum together.

It’s a precise, efficient method, and what’s amazing about it is that it works without the need for excessive heat input that you’d get from traditional welding methods like MIG or TIG.

The laser’s energy is so concentrated that it only affects the area right where you need the joint to be, minimizing the chance of warping or distortion.

A while back, I was helping out at a small shop that specializes in custom aluminum parts.

One of the most challenging tasks we had was joining thin sheets of aluminum—too much heat would warp them, and we didn't want to risk that.

After switching to a laser welding setup, we were able to get beautifully precise welds with minimal distortion. It felt like magic, honestly.

With the Advancement of Modern Technology

Laser Welding Machine Price has Never been this Affordable!

Why Laser Welding Aluminum?

Aluminum's Reflective Surface and Low Melting Point, Can be Tricky to Weld

Aluminum, with its reflective surface and low melting point, can be a tricky material to weld.

The reflectivity can throw off a lot of the energy from traditional welding tools, and aluminum’s low melting point means it can be prone to burn-through if you're not careful.

Enter laser welding.

The laser beam is incredibly focused, so it bypasses much of the usual problems you’d face with other techniques.

This precision allows you to weld even the most delicate aluminum without messing up the integrity of the surrounding material.

Plus, since the process is typically done in a protective gas atmosphere (like argon), oxidation is kept to a minimum, ensuring clean, strong welds.

I remember when I first tried to weld a piece of aluminum using a traditional MIG welder—let’s just say it didn’t go well.

The welds were uneven, and the edges got all warped.

But when I switched to a laser setup, the results were night and day.

The precision and clean finish were astonishing, and I could literally feel the difference in the way the material behaved.

Metal Laser Welding Machine Aluminum

Choosing Between Different Types of Laser Welding Machine?

We Can Help Make the Right Decision Based on Applications

The Benefits of Laser Welding Aluminum

There are some Real Perks to Using a Laser for Aluminum Welding

One time, we were working on a batch of aluminum parts for a high-end automotive client.

The final finish needed to be spotless, no grinding or rework.

Laser welding didn’t just meet that standard—it exceeded it.

The welds came out so smooth, they were almost too perfect.

The client was thrilled, and I have to admit, I was kind of proud of how neat the whole process was.

Precision

As I mentioned before, the laser’s focused energy means you can weld very thin materials with minimal heat input.

It’s like using a fine-tipped pen to write instead of a thick marker.

Minimal Distortion

Since the heat is localized, there’s much less chance of warping, which is huge when working with thin-walled aluminum parts.

I’ve seen it firsthand—where traditional welding methods would cause the metal to twist and bend, laser welding keeps things in check.

High-Speed Welding

Laser welding is often faster than conventional methods, which can boost productivity.

Whether you’re working on a high-volume production line or a one-off custom piece, the speed can really make a difference.

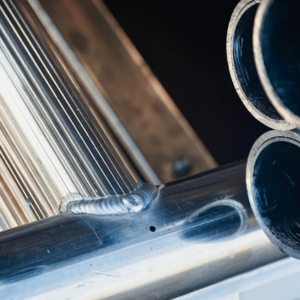

Cleaner Welds

The welds typically come out cleaner, needing less post-processing.

In industries where the appearance of the final product is as important as its strength (think automotive or aerospace), this is a huge advantage.

Welding Aluminum is Difficult with Traditional Welding

Laser Welding Simplify this Process

Reminders for Laser Welding Aluminum

Laser Welding Aluminum is Fantastic, it’s not Without its Considerations

While laser welding aluminum is fantastic, it’s not without its considerations.

For one, the equipment can be pricey and requires a bit of a learning curve to set up and maintain properly.

I’ve seen people get frustrated trying to adjust the settings for different thicknesses or types of aluminum—there’s a real balance to strike between power, speed, and focus.

Also, aluminum doesn’t always like being welded—it tends to develop oxide layers that can make things trickier.

Some lasers use a method called “laser beam welding” (LBW), where a filler material is added in, but in aluminum, the right filler and shielding gas are crucial to get a good weld without issues like porosity or contamination.

Laser Welding Aluminum Machine

The Future of Aluminum Welding

Laser welding aluminum is undeniably one of those techniques that feels like it’s always on the cutting edge.

Whether you're working on tiny precision parts for electronics or larger components for vehicles, it’s a tool that’s revolutionized the way we approach welding.

From my experience, once you get the hang of it, laser welding can feel like the “easier” route—less fuss, less mess, but still strong and reliable joints.

So, if you’re looking for clean, efficient, and precise welds on aluminum, it’s definitely worth considering this method.

Just remember: laser welding isn’t the be-all and end-all solution for everything.

Like anything else, it has its time and place. But when it’s the right tool for the job, it can make all the difference in the world—trust me, I’ve seen it firsthand.

Want to Know More about Laser Welding Aluminum?

Welding Aluminum is Tricker than Welding Other Materials.

Therefore We Wrote an Article all about How to Achieve Good Welds with Aluminum.

From Settings to How to.

With Videos and Other Information.

Interested in Laser Welding Other Materials?

Want to Get Started on Laser Welding Fast?

Want to Refresh your Knowledge of Laser Welding?

This Complete Reference Guide is Tailored just For you!

High-Capacity & Wattage for Various Welding Applications

The 2000W handheld laser welding machine is characterized by small machine size but sparkling welding quality.

A stable fiber laser source and connected fiber cable provide a safe and steady laser beam delivery.

With the high power, the laser welding keyhole is perfectible and enables the welding joint firmer even for thick metal.

Portability for Flexibility

With a compact and small machine appearance, the portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight and convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles and automatic wire feeding systems make laser welding operation easier and that is friendly for beginners.

High-speed laser welding greatly increases your production efficiency and output while enabling an excellent laser welding effect.

Things You NEED to Know about: Handheld Laser Welding

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Dec-27-2024