Laser Welding Secrets: Fix Common Issues Now!

Introduction:

A Complete Guide to Troubleshooting

Handheld Laser Welding Machines

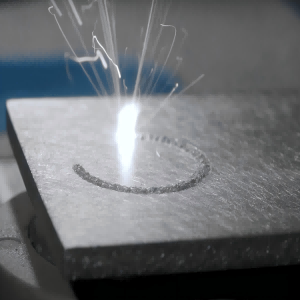

Handheld fiber laser welding machine has gained immense popularity in various industries due to its precision and efficiency.

However, like any other welding technique, it is not immune to challenges and issues that may arise during the welding process.

This comprehensive laser welding troubleshooting aims to address common problems encountered with handheld laser welding machines, welding-related complications, and issues concerning the quality of welds.

Pre-Start Laser Welding Machine Faults & Solutions

1. Equipment Cannot Start (Power)

Solution: Check whether the power cord switch is powered.

2. Lights Cannot Be Lit

Solution: Check the pre-fire board with or without 220V voltage, check the light board; 3A fuse, xenon lamp.

3. The light Has Been Lit, No Laser

Solution: Observe the handheld laser welding machine part of the display out of the light is normal. First of all, check the CNC part of the laser button is closed, if closed, then open the laser button. If the laser button is normal, open the numerical control display interface to see whether the setting for continuous light, if not, then change to continuous light.

Welding Phase Laser Welder Issues & Fixes

The Weld Seam Is Black

The protective gas is not open, as long as the nitrogen gas is opened, it can be solved.

The airflow direction of the protective gas is wrong, the airflow direction of the protective gas should be made opposite to the movement direction of the work piece.

Lack Of Penetration In Welding

Lack of laser energy can improve the pulse width and current.

The focusing lens is not the correct amount, to adjust the focusing amount close to the focusing position.

Weakening Of The Laser Beam

If the cooling water is contaminated or has not been replaced for a long time, it can be solved by replacing the cooling water and cleaning the UV glass tube and xenon lamp.

The focusing lens or resonant cavity diaphragm of the laser is damaged or polluted, it should be replaced or cleaned in time.

Move the laser in the main optical path, adjust the total reflection and semi-reflection diaphragm in the main optical path, check and round the spot with image paper.

The laser does not output from the copper nozzle below the focusing head. Adjust the 45-degree reflective diaphragm so that the laser is output from the center of the gas nozzle.

Laser Welding Quality Troubleshooting

1.Spatter

After laser welding is completed, many metal particles appear on the surface of the material or work piece, attached to the surface of the material or work piece.

Reason for spattering: the surface of the processed material or work piece is not clean, there is oil or pollutants, it may also be caused by the volatilization of the galvanized layer.

1) Pay attention to cleaning the material or work piece before laser welding;

2) Spatter is directly related to power density. Appropriate reduction of welding energy can reduce spatter.

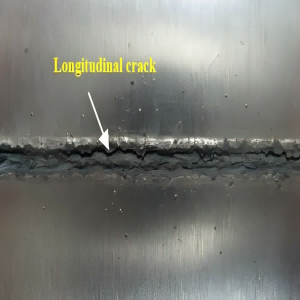

2. Cracks

If the cooling speed of the workpiece is too fast, the temperature of the cooling water should be adjusted on the fixture to increase the water temperature.

When the workpiece fit gap is too large or there is burr, the machining precision of the workpiece should be improved.

The workpiece has not been cleaned. In this case, the workpiece needs to be cleaned again.

The flow rate of protective gas is too large, which can be solved by reducing the flow rate of protective gas.

3. Pore On The Weld Surface

Reasons for the generation of porosity:

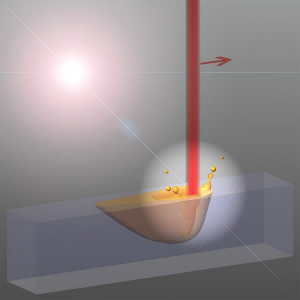

1) The laser welding molten pool is deep and narrow, and the cooling rate is very fast. The gas generated in the molten pool is too late to overflow, which can easily lead to the formation of porosity.

2) The surface of the weld is not cleaned, or the zinc vapor of the galvanized sheet is volatilized.

Clean the surface of the workpiece and the surface of the weld before welding to improve the volatilization of zinc when heated.

4. Welding Deviation

The weld metal will not solidify in the center of the joint structure.

Reason for deviation: Inaccurate positioning during welding, or inaccurate filling time and wire alignment.

Solution: Adjust the welding position, or filler time and wire position, as well as the position of the lamp, wire and weld.

5. Surface Slag Entrapment, Which Mainly Appears Between Layers

Surface slag entrapment causes:

1) When multi-layer multi-pass welding, the coating between layers is not clean; or the surface of the previous weld is not flat or the surface of the weld does not meet the requirements.

2) Improper welding operation techniques, such as low welding input energy, welding speed is too fast.

Solution: Choose reasonable welding current and welding speed, and the interlayer coating must be cleaned when multi-layer multi-pass welding. Grind and remove the weld with slag on the surface, and make up the weld if necessary.

Other Accessories – Handheld Laser Welder Common Problems and Solutions

1. Failure of Safety Protection Device

The safety protection devices of the laser welding machine, such as the welding chamber door, gas flow sensor, and temperature sensor, are crucial for its proper functioning. Failure of these devices can not only disrupt the normal operation of the equipment but also pose a risk of injury to the operator.

In the event of a malfunction with the safety protection devices, it is imperative to halt the operation at once and contact professionals for repair and replacement.

2. Wire Feeder Jamming

If there is a wire feeder jam this situation, the first thing we need to do is to check whether the gun nozzle is clogged, the second step is to check whether the wire feeder is clogged and there is the silk disk rotation is normal.

Summarize

With unmatched precision, speed and versatility, laser welding is a valuable technology in industries such as automotive, aerospace and electronics.

However, various defects may occur during the welding process, including porosity, cracking, splashing, irregular bead, burn-out, deformation, and oxidation.

Each defect has a specific cause, such as improper laser Settings, material impurities, insufficient protective gases, or misaligned joints.

By understanding these defects and their root causes, manufacturers can implement targeted solutions, such as optimizing laser parameters, ensuring proper joint fit, using high-quality protective gases, and applying pre - and post-weld treatments.

Proper operator training, daily equipment maintenance and real-time process monitoring further improve welding quality and minimize defects.

With a comprehensive approach to defect prevention and process optimization, laser welding consistently delivers robust, reliable and high-quality welds that meet stringent industry standards.

Don't know which type of laser welding machine to choose?

You need to know: How to choose a handheld laser machine

High-Capacity & Wattage for Various Welding Applications

The 2000W handheld laser welding machine is characterized by small machine size but sparkling welding quality.

A stable fiber laser source and connected fiber cable provide a safe and steady laser beam delivery.

With the high power, the laser welding keyhole is perfectible and enables the welding joint firmer even for thick metal.

Portability for Flexibility

With a compact and small machine appearance, the portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight and convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles and automatic wire feeding systems make laser welding operation easier and that is friendly for beginners.

High-speed laser welding greatly increases your production efficiency and output while enabling an excellent laser welding effect.

Things You Need to Know about: Handheld Laser Welding

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Jan-16-2025