Laser Welding vs TIG Welding: What Changed in 2024

What is Handheld Laser Welding?

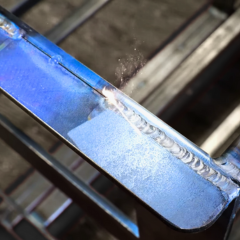

Handheld Laser Welding Stainless Steel

Handheld laser welding utilizes a portable laser device to join materials, typically metals.

Handheld laser welding allows for greater maneuverability and precision,

And produces a high-quality, clean weld with minimal heat input,

Reducing distortion and the need for extensive post-weld processing.

Operators can easily adjust the power and speed of the laser,

Enabling tailored settings for different materials and thicknesses.

Table of Content:

What is Laser Weld Cleaning?

Importance of Cleanliness in Welding

Pre-Weld Cleaning for TIG Welding

When it comes to welding,

Cleanliness plays a crucial role in achieving high-quality results.

This principle applies to both TIG welding and handheld laser welding,

But the methods of preparing the material differ significantly.

For any welding process,

The presence of contaminants such as rust, paint, and grease

Can severely compromise the integrity of the weld.

These impurities can lead to weak joints, porosity, and other defects

That undermine the strength of the final product.

This is How you SHOULD Deal with these Contaminants: Laser Weld Cleaning.

Laser Welding vs TIG Welding: Laser Weld Cleaning

Cleaned Surfaces Produces High-Quality Welds

Laser Weld Cleaning for Handheld Laser Cleaning

While TIG welding relies on manual cleaning methods like angle grinding and acetone wiping,

Handheld laser welding offers a more convenient alternative with its integrated cleaning capabilities.

This innovation not only enhances efficiency

But also ensures that the welding process is as effective as possible,

Ultimately leading to better results.

TIG Welding Preparation:

In TIG (Tungsten Inert Gas) welding, meticulous preparation is essential.

Before starting the welding process,

It is common to use angle grinders to remove rust or coatings from the surface of the material.

This mechanical cleaning helps ensure that the surface is free from impurities.

Following this, a thorough wipe with acetone is typically performed.

Acetone is a powerful solvent that effectively removes any remaining grease or contaminants,

Leaving a clean surface for the weld.

This two-step cleaning process can be time-consuming,

But it is vital for achieving a strong and durable weld.

Handheld Laser Welding Preparation

In contrast, handheld laser welding offers

A more streamlined approach to surface preparation.

With a 3-in-1 laser welder, the process becomes significantly easier.

These advanced machines typically come equipped with interchangeable nozzles

That allow for surface cleaning right before welding.

Unlike traditional methods, where separate tools and cleaning agents are required,

Laser welders can effortlessly clean the surface with a focused laser beam.

This not only saves time but also reduces the amount of equipment needed on-site.

Laser Welding vs TIG Welding has Changed in 2024

Contact Us for More about Handheld Laser Welding System

Why Use Shielding Gas in Welding?

The Choice of Shielding Gas Plays a Critical Role

Shielding Gas for TIG Welding: Argon

When it comes to welding,

The choice of shielding gas is essential for ensuring high-quality results.

In particular, TIG welding and handheld laser welding have different requirements and options

When it comes to shielding gases, impacting both performance and cost.

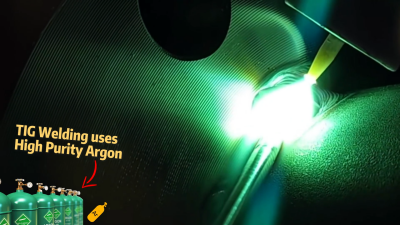

Shielding Gas in TIG Welding

In TIG (Tungsten Inert Gas) welding,

The primary shielding gas used is high-purity argon.

This noble gas is chosen for its excellent ability to protect the weld pool

From atmospheric contamination, particularly oxidation.

Oxidation can lead to defects in the weld, such as porosity and weak joints,

Which compromises the overall integrity of the metal.

Because of its effectiveness,

TIG welding often requires a continuous supply of argon throughout the welding process.

However, argon can be relatively expensive, leading to higher operational costs,

Especially in projects that require extensive welding.

Shielding Gas in Handheld Laser Welding

Alternative Shielding Gas for Laser Welding: Nitrogen

On the other hand, handheld laser welding often utilizes nitrogen as a shielding gas.

Nitrogen is not only effective at preventing oxidation

But is also significantly more cost-effective than argon.

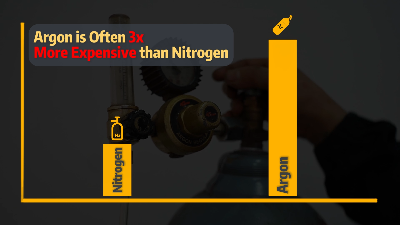

The price difference can be substantial;

Nitrogen can be almost three times cheaper than high-purity argon.

This makes nitrogen an attractive option for businesses looking to reduce costs without sacrificing quality.

TIG vs Laser Welding: Shielding Gas Options

Achieve Savings While Maintaining Quality

Price Comparison Between Argon and Nitrogen

Switching to nitrogen in handheld laser welding offers several advantages

Cost Savings:

With the significant price difference between argon and nitrogen,

Using nitrogen can lead to substantial savings over time.

This is particularly beneficial for large projects or businesses

That perform frequent welding operations.

Effective Protection:

Nitrogen provides adequate shielding against oxidation,

Ensuring that the weld remains clean and strong.

While argon is known for its superior protection,

Nitrogen is still a viable option that effectively meets the needs of many welding applications.

Compare the Welding Process: Laser vs TIG Welding

Careful Attention to Technique Achieves the Best Results

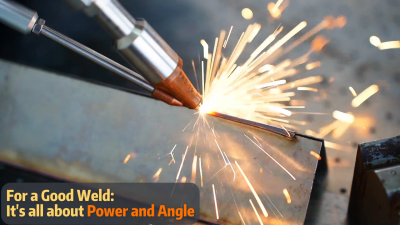

The Right Angle for Laser Welding: 45 Degree

Once the shielding gas is properly flowing,

It's time to focus on the actual welding process.

Both TIG (Tungsten Inert Gas) welding and handheld laser welding

Require precise techniques to achieve high-quality results,

However, they differ in their specific requirements and methods.

TIG Welding Technique

Aim to maintain the electrode at an optimal distance and speed to form and lead the weld pool.

This distance can vary depending on the material and thickness being welded.

Maintaining the correct angle, usually around 15 to 20 degrees,

Helps in achieving a consistent and clean weld.

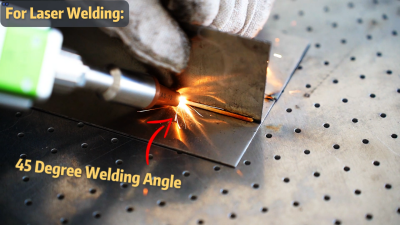

Handheld Laser Welding Technique

One of the benefits of laser welding is the ability to set a consistent angle

Typically around 45 degrees, allowing for easier management of the welding process.

Once the angle is set, maintaining a steady speed is key.

Handheld laser welding typically produces less heat compared to TIG welding.

This means that there is less risk of warping or distortion,

Making it ideal for precision work on thinner materials.

Laser Weld Strength vs TIG: Debunking Myths

Common Misconception Regarding Laser Welding

For Good Handheld Laser Welding: Power & Angle

One of the key advantages of handheld laser welding is its ability to deliver concentrated energy precisely where it is needed.

With the right power settings and an optimal angle

Typically around 45 degrees, laser welding can achieve excellent penetration and strength.

The Right Power Output

The power setting of the laser welder is crucial.

Too low of a power output can result in insufficient penetration, leading to weak welds.

Conversely, an appropriate power level allows the laser to melt the material effectively, creating strong joints.

Using underpowered equipment won't yield the desired results.

Both TIG and Handheld Laser Welding are Efficient

Want to Learn More About Handheld Laser Welding?

Handheld Laser Welding: How to Maintain Equipment

Proper Care and Attention to Detail will Ensure Productivity and Reliability

Did you know that both TIG (Tungsten Inert Gas) welding and handheld laser welding are classified as

Non-consumable welding methods?

This means that, under ideal conditions and with proper care,

The key components used in these processes can last a long time

Without needing frequent replacement.

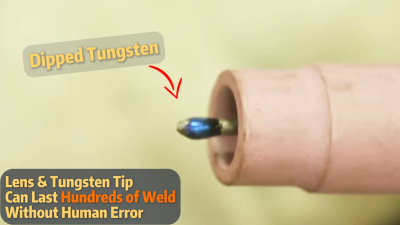

Non-Consumable Components

Dipped Tungsten Error for TIG Welding

The tungsten electrode is a critical component in TIG welding.

Unlike consumable electrodes used in other welding methods,

such as MIG welding, the tungsten electrode does not melt during the welding process.

Instead, it maintains its integrity, allowing for prolonged use.

However, the electrode can become contaminated or "dipped" if it gets too close to the molten weld pool.

In such cases, it must be cut back and ground to restore its sharp point and effective performance.

Regular maintenance of the tungsten electrode is essential for achieving clean, high-quality welds.

Handheld Laser Welding Preparation

Laser Lens for Handheld Laser Welding Maintenance

In handheld laser welding, the laser lens serves as the focal point for the laser beam.

A properly positioned lens can last a long time, providing consistent performance.

However, if the lens becomes cracked due to improper positioning or exposure to excessive heat

It will need to be replaced.

Maintaining the lens in good condition is crucial,

As even minor damage can affect the accuracy and effectiveness of the laser, leading to suboptimal welds.

Want a Complete Reference Guide for Handheld Laser Welding?

Handheld laser welding offers numerous advantages,

But it also requires meticulous attention to safety protocols.

This article will explore the key safety considerations for handheld laser welding.

As well as provide recommendations on shielding gas selection and filler wire choices for common metal types.

Is Laser Welding as Strong as TIG Welding?

Laser welding and TIG (Tungsten Inert Gas) welding are both renowned for their precision and quality in metal joining.

But how do they stack up against each other in terms of strength?

In this video, we’ll dive into the key differences in weld performance, material compatibility, and overall durability between laser and TIG welding.

Handheld Fiber Laser Welding (Handheld Laser Weld)

A Valuable Addition to the Handheld Laser Weld Landscape

Small Laser Welder Makes Welding Cost-effective & Affordable

With a compact and small machine appearance.

The portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight.

And convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles.

An optional automatic wire feeding system makes laser welding operation easier and that is friendly for beginners.

5 Things About Laser Welding (That you Missed)

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Handheld Laser Weld is an Excellent Choice for Manual Welding Tasks

And the Future Starts with You!

Post time: Sep-14-2024