lluminating the Differences:

Delving into Laser Marking, Etching and Engraving

Laser processing is a powerful technology used to create permanent markings and engravings on material surfaces. Laser marking, laser etching, and laser engraving processes are becoming increasingly popular. Although these three techniques may appear similar, there are several differences between them.

The difference between laser marking, engraving, and etching lies in the depth at which the laser works to create the desired pattern. While laser marking is a surface phenomenon, etching involves material removal at a depth of approximately 0.001 inches, and laser engraving involves material removal ranging from 0.001 inches to 0.125 inches.

What is laser marking:

Laser marking is a technique that uses a laser beam to discolor the material and create permanent markings on the surface of a workpiece. Unlike other laser processes, laser marking does not involve material removal, and the marking is generated by altering the physical or chemical properties of the material.

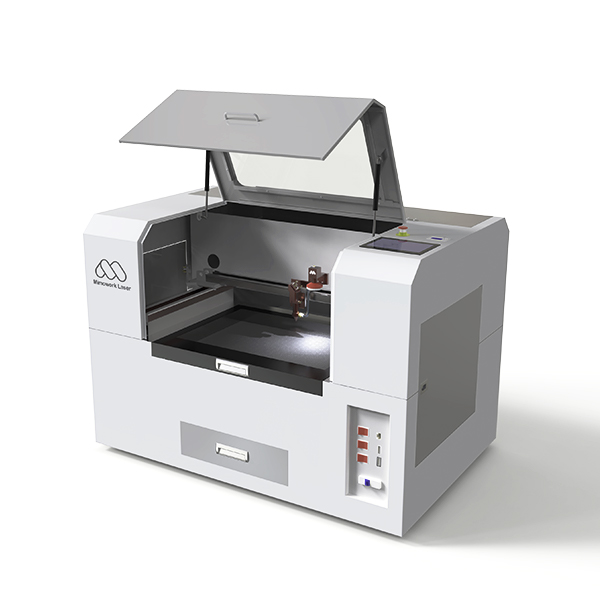

Typically, low-power desktop laser engraving machines are suitable for marking various types of materials. In this process, a low-power laser beam moves across the material surface to trigger chemical changes, resulting in the darkening of the target material. This produces a high-contrast permanent marking on the material surface. It is commonly used for applications such as marking manufacturing parts with serial numbers, QR codes, barcodes, logos, etc.

Video Guide -CO2 Galvo Laser Marking

What is laser engraving:

Laser engraving is a process that requires relatively more laser power compared to laser marking. In this process, the laser beam melts and vaporizes the material to create voids in the desired shape. Typically, material removal accompanies surface darkening during laser engraving, resulting in visible engravings with high contrast.

Video Guide -Engraved Wood Ideas

The maximum working depth for standard laser engraving is approximately 0.001 inches to 0.005 inches, while deep laser engraving can achieve a maximum working depth of 0.125 inches. The deeper the laser engraving, the stronger its resistance to abrasive conditions, thus extending the lifespan of the laser engraving.

What is laser etching:

Laser etching is a process that involves melting the surface of the workpiece using high-energy lasers and producing visible marks by generating micro-protrusions and color changes in the material. These micro-protrusions alter the material's reflective characteristics, creating the desired shape of visible marks. Laser etching may also involve material removal at a maximum depth of approximately 0.001 inches.

Although it is similar to laser marking in operation, laser etching requires relatively more laser power for material removal and is typically performed in areas where durable markings with minimal material removal are needed. Laser etching is usually carried out using medium-power laser engraving machines, and the processing speed is slower compared to engraving similar materials.

Special Applications:

Like the pictures shown above, we can find them in the store as gifts, decorations, trophies, and souvenirs. The photo seems floating inside the block and presents in a 3D model. You can see it in different appearances at any angle. That's why we call it 3D laser engraving, subsurface laser engraving (SSLE), 3D crystal engraving or inner laser engraving. There is another interesting name for "bubblegram". It vividly describes the tiny points of fracture made by laser impact like bubbles.

✦ Permanent laser marking sign while scratch-resistance

✦ Galvo laser head directs flexible laser beams to complete customized laser marking patterns

✦ High repeatability improves productivity

✦ Easy operation for fiber laser photo engraving ezcad

✦ Reliable fiber laser source with long service life, less maintenance

Contact Us for Detailed Customer Support!

▶ Want to Find the Suitable One for You?

How About These Options to Choose From?

▶ About Us - MimoWork Laser

We are the Firm Support Behind Our Customers

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industry.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

MimoWork has been committed to the creation and upgrade of laser production and developed dozens of advanced laser technology to further improve clients' production capacity as well as great efficiency. Gaining many laser technology patents, we are always concentrating on the quality and safety of laser machine systems to ensure consistent and reliable processing production. The laser machine quality is certificated by CE and FDA.

Get More Ideas from Our YouTube Channel

Having Any Problems About Our Laser Products?

We are Here to Help!

Post time: Jul-05-2023