Discover the Art of Laser Engrave Stone:

A Comprehensive Guide

For Stone Engraving, Marking, Etching

Contents

Types of Stone for Stone Engraving Laser

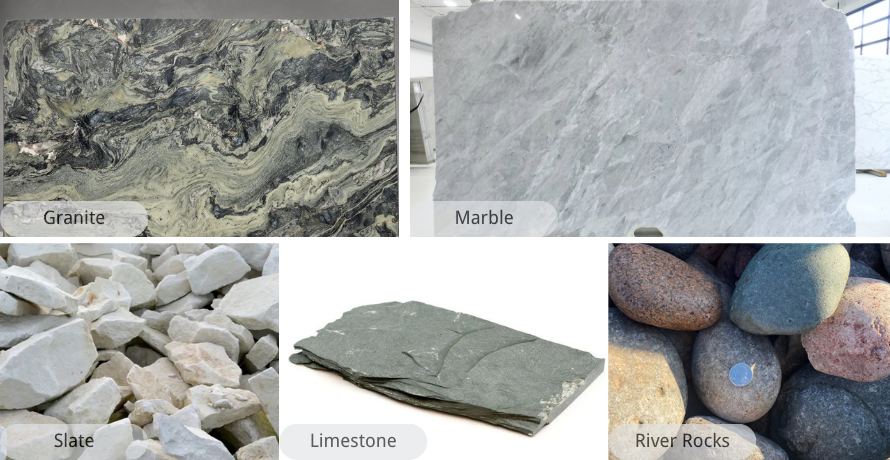

When it comes to laser engraving, not all stones are created equal.

Here are some popular types of stone that work well:

1. Granite:

Known for its durability and variety of colors, granite is a popular choice for memorials and plaques.

2. Marble:

With its elegant appearance, marble is often used for high-end decorative items and sculptures.

3. Slate:

Ideal for coasters and signage, slate’s natural texture adds a rustic touch to engravings.

4. Limestone:

Soft and easy to engrave, limestone is frequently used for architectural elements.

5. River Rocks:

These smooth stones can be personalized for garden decor or gifts.

What You Can Do with Laser Engraver for Stone

Laser Machines are Designed for Precision and Efficiency.

Making them Perfect for Stone Engraving.

Here’s what you can Create:

• Custom Monuments: Create personalized memorial stones with detailed engravings.

• Decorative Art: Design unique wall art or sculptures using different stone types.

• Functional Items: Engrave coasters, cutting boards, or garden stones for practical yet beautiful uses.

• Signage: Produce durable outdoor signage that withstands the elements.

Video Display:

Laser Distinguishes Your Stone Coaster

Stone Coasters, Especially Slate Coasters are Very Popular!

Aesthetic appeal, durability, and heat resistance. They are often considered upscale and are frequently used in modern and minimalist decor.

Behind the exquisite stone coasters, there is laser engraving technology and our loved stone laser engraver.

Via dozens of tests and improvements in laser technology, the CO2 laser is verified to be great for slate stone in engraving effect and engraving efficiency.

So What Stone are you Working With? What Laser is the MOST Suitable?

Keep reading to find out.

Top 3 Creative Projects for Stone Laser Engraving

1. Personalized Pet Memorials:

Engrave a beloved pet's name and a special message on a granite stone.

2. Engraved Garden Markers:

Use slate to create stylish markers for plants and herbs in your garden.

3. Custom Awards:

Design elegant awards using polished marble for ceremonies or corporate events.

What Are the Best Stones for Laser Engraving Machine?

The best stones for laser engraving typically have smooth surfaces and a consistent texture.

Here’s a summary of the top choices:

• Granite: Excellent for detailed designs and long-lasting results.

• Marble: Great for artistic projects due to its variety of colors and patterns.

• Slate: Offers a rustic aesthetic, perfect for home decor.

• Limestone: Easier to engrave, ideal for intricate designs but may not be as durable as granite.

Stone Laser Engraver Ideas

• Family Name Signs: Create a welcoming entryway sign for homes.

• Inspirational Quotes: Engrave motivational messages on stones for home decor.

• Wedding Favors: Personalized stones as unique keepsakes for guests.

• Artistic Portraits: Transform photos into beautiful stone engravings.

Advantages of Laser Engraved Stone Compared to Sandblasting and Mechanical Engraving

Laser engraving offers several advantages over traditional methods:

• Precision:

Lasers can achieve intricate details that are difficult with sandblasting or mechanical methods.

• Speed:

Laser engraving is generally faster, allowing for quicker project completion.

• Less Material Waste:

Laser engraving minimizes waste by focusing precisely on the design area.

• Versatility:

A variety of designs can be created without changing tools, unlike sandblasting.

How to Select the Right Stone Engraving Laser Machine

When selecting stone for laser engraving, consider the following factors:

• Surface Smoothness:

A smooth surface ensures better engraving fidelity.

• Durability:

Choose stones that can withstand outdoor conditions if the item will be displayed outside.

• Color and Texture:

The color of the stone can impact the visibility of the engraving, so choose a contrasting color for best results.

How to Engrave Rocks and Stones with Laser Stone Engraving

Engraving stones with lasers involves several steps:

1. Design Creation:

Use graphic design software to create or import your engraving design.

2. Material Preparation:

Clean the stone to remove any dust or debris.

3. Machine Setup:

Load the design into the laser engraving machine and adjust settings based on the stone type.

4. Engraving Process:

Start the engraving process and monitor the machine to ensure quality.

5. Finishing Touches:

After engraving, clean off any residue and apply a sealant if necessary to protect the design.

Laser engraving stone opens up a world of creativity, offering both artisans and businesses the chance to produce stunning, personalized items.

With the right materials and techniques, the possibilities are endless.

That means the laser head keeps well-performing in the long term, you don't replace it.

And for the material to be engraved, no crack, no distortion.

Recommended Stone Laser Engraver

CO2 Laser Engraver 130

CO2 laser is the most common laser type for engraving and etching stones.

The Mimowork’s Flatbed Laser Cutter 130 is mainly for laser cutting and engraving solid materials like stone, acrylic, wood.

With the option equipped with a 300W CO2 laser tube, you can try the deep engraving on the stone, creating a more visible and clear mark.

The two-way penetration design allows you to place materials that extend beyond the working table width.

If you want to achieve high-speed engraving, we can upgrade the step motor to DC brushless servo motor and reach the engraving speed of 2000mm/s.

Machine Specification

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Fiber laser is an alternative to CO2 laser.

The fiber laser marking machine uses fiber laser beams to make permanent marks on the surface of various materials including stone.

By evaporating or burning off the surface of the material with light energy, the deeper layer reveals then you can get a carving effect on your products.

Machine Specification

| Working Area (W * L) | 70*70mm, 110*110mm, 175*175mm, 200*200mm (optional) |

| Beam Delivery | 3D Galvanommeter |

| Laser Source | Fiber Lasers |

| Laser Power | 20W/30W/50W |

| Wavelength | 1064nm |

| Laser Pulse Frequency | 20-80Khz |

| Marking Speed | 8000mm/s |

| Repetition Precision | within 0.01mm |

Which Laser is Suitable for Engraving Stone?

CO2 LASER

Advantages:

① Wide versatility.

Most stones can be engraved by CO2 laser.

For example, for engraving quartz with reflective properties, CO2 laser is the only to make it.

② Rich engraving effects.

CO2 laser can realize diverse engraving effects and different engraving depths, on one machine.

③ Larger working area.

CO2 stone laser engraver can handle larger formats of stone products to finish engraving, like gravestones.

(We tested stone engraving to make a coaster, using a 150W CO2 stone laser engraver, the efficiency is the highest compared with the fiber at the same price.)

Disadvantages:

① Large machine size.

② For small and extremely fine patterns like portraits, fiber sculpts better.

FIBER LASER

Advantages:

① Higher precision in engraving and marking.

Fiber laser can create very detailed portrait engraving.

② Fast speed for light marking and etching.

③ Small machine size, making it space-saving.

Disadvantages:

① The engraving effect is limited to shallow engraving, for a lower-power fiber laser marker like 20W.

Deeper engraving is possible but for multiple passes and a longer time.

② The machine price is so expensive for higher power like 100W, compared with CO2 laser.

③ Some stone types can not be engraved by fiber laser.

④ Due to the small working area, the fiber laser can not engrave larger stone products.

DIODE LASER

Diode laser is not suitable for engraving stone, due to its lower power, and simper exhaust device.

FAQs of Laser Engraving Stone

• Is There a Difference in the Engraving Process for Different Stones?

Yes, different stones may require different laser settings (speed, power, and frequency).

Softer stones like limestone engrave more easily than harder stones like granite, which may need higher power settings.

• What is the Best Way to Prepare Stone for Engraving?

Before engraving, clean the stone to remove any dust, dirt, or oils.

This ensures better adhesion of the design and improves the quality of the engraving.

• Can I Engrave Photos on Stone?

Yes! Laser engraving can reproduce images and photos on stone surfaces, providing a beautiful and personalized result.

High-resolution images work best for this purpose.

• What Equipment do I Need for Laser Engraving Stone?

To engrave stone, you will need:

• A laser engraving machine

• Design software (e.g., Adobe Illustrator or CorelDRAW)

• Proper safety equipment (goggles, ventilation)

Want to Know More About

Laser Engraving Stone

Want to Get Started with Laser Engraving Stone?

Post time: Jan-10-2025