The Ultimate Guide to Laser Cutting Filter Cloth:

Types, Benefits, and Applications

Introduction:

Key Things to Know Before Diving In

Filter cloths play an essential role in a wide array of industries, from water and air filtration to pharmaceutical and food processing. As businesses seek to improve efficiency, precision, and customization in the production of filter cloth, laser cutting filter cloth has emerged as a preferred solution. Unlike traditional cutting methods, laser cutting filter cloth offers a high degree of precision, speed, and minimal material waste, making it an ideal choice for cutting filter cloths made from various materials such as polyester, nylon, and nonwoven fabrics.

In this article, we will explore the different types of filter cloth, how laser cutting filter cloth works on each material, and why it is the ideal choice for high-quality, customized filtration products. Additionally, we will discuss some of the results from our recent testing with various filter cloth materials, such as foam and polyester, to provide real-world examples of how laser cutting filter cloth can enhance production.

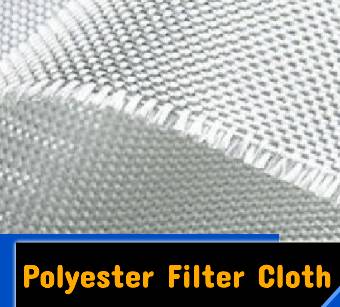

1. Polyester Filter Cloth:

• Usage: Polyester filter cloth is one of the most commonly used materials in filtration due to its durability, chemical resistance, and ability to withstand high temperatures.

• Applications: It's often used in air filtration systems, water treatment, and industrial filtration systems.

• Benefits for Laser Cutting: Polyester is highly compatible with laser cutting filter cloth because it produces clean, precise edges. The laser also seals the edges, preventing fraying and enhancing the cloth's overall strength.

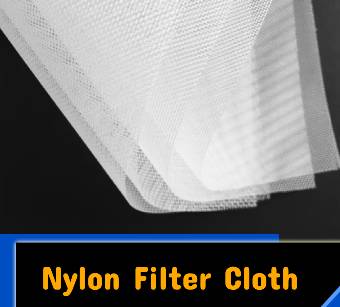

2. Nylon Filter Cloth:

• Usage: Known for its flexibility and toughness, nylon filter cloth is ideal for demanding filtration applications, such as in chemical industries or in the food and beverage sector.

• Applications: Commonly used for chemical filtration, water treatment, and food processing filtration.

• Benefits for Laser Cutting: Nylon's strength and resistance to wear make it an excellent candidate for laser cutting filter cloth. The laser ensures smooth, sealed edges that maintain the material's durability and filtration properties.

3. Polypropylene Filter Cloth:

• Usage: Polypropylene is known for its excellent chemical resistance, making it ideal for filtering aggressive chemicals or high-temperature substances.

• Applications: It’s used in pharmaceutical filtration, industrial filtration, and liquid filtration.

• Benefits for Laser Cutting: Laser cutting filter cloth like polypropylene allows for precise cuts and intricate designs without damaging the material. The sealed edges provide better structural integrity, making it suitable for critical applications.

4. Nonwoven Filter Cloth:

• Usage: Nonwoven filter cloth is lightweight, flexible, and cost-effective. It’s used in applications where ease of use and low pressure are important.

• Applications: Used in automotive, air, and dust filtration, as well as in disposable filter products.

• Benefits for Laser Cutting: Nonwoven fabrics can be laser cut quickly and efficiently. Laser cutting filter cloth is highly versatile for different filtration needs, allowing for both fine perforations and large-area cuts.

Laser cutting filter cloth works by focusing a high-powered laser beam on the material, which melts or vaporizes the material at the point of contact. The laser beam is controlled with great precision by a CNC (Computer Numerical Control) system, allowing it to cut through or engrave various filter cloth materials with exceptional accuracy.

Each type of filter cloth requires specific settings to ensure optimal cutting results. Here’s a look at how laser cutting filter cloth works for some of the most common filter cloth materials:

Laser Cut Polyester:

Polyester is a synthetic fabric that reacts well to laser cutting filter cloth.

The laser cuts smoothly through the material, and the heat from the laser beam seals the edges, preventing any unraveling or fraying.

This is especially important in filtration applications where clean edges are essential for maintaining the integrity of the filter.

Laser Cut Nonwoven Fabrics:

Nonwoven fabrics are lightweight and delicate, making them well-suited for laser cutting filter cloth. The laser can quickly cut through these materials without damaging their structure, providing clean cuts that are essential for producing precise filter shapes. Laser cutting filter cloth is particularly beneficial for nonwoven fabrics used in medical or automotive filtration applications.

Laser Cut Nylon:

Nylon is a strong, flexible material that is ideal for laser cutting filter cloth. The laser beam easily cuts through nylon and creates sealed, smooth edges. Additionally, laser cutting filter cloth does not cause distortion or stretching, which is often a problem with traditional cutting methods. The high precision of laser cutting filter cloth ensures that the final product maintains the necessary filtration performance.

Laser Cut Foam:

Foam filter materials are also suitable for laser cutting filter cloth, especially when precise perforations or cuts are required. Laser cutting filter cloth like foam allows for intricate designs and ensures that the edges are sealed, which prevents the foam from degrading or losing its structural properties. However, care must be taken with settings to prevent excessive heat buildup, which could cause burning or melting.

Laser cutting filter cloth offers numerous benefits over traditional cutting methods, particularly for filter cloth materials. Here are some of the key advantages:

1. Precision and Clean Edge

Laser cutting filter cloth ensures precise cuts with clean, sealed edges, which is crucial for maintaining the structural integrity of the filter cloth. This is especially important in filtration systems where the material must maintain its ability to filter efficiently.

2. Fast Speed & High Efficiency

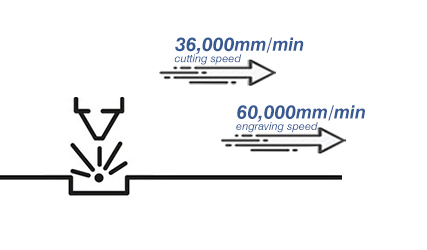

Laser cutting filter cloth is faster and more efficient than mechanical or die-cutting methods, especially for intricate or custom designs. The filter cloth laser cutting system can also be automated, reducing the need for manual intervention and speeding up production times.

3. Minimal Material Waste

Traditional cutting methods often create excess material waste, especially when cutting complex shapes. Laser cutting filter cloth offers high precision and minimal material wastage, making it a cost-effective option for both small and large-scale production.

4. Customization and Flexibility

Laser cutting filter cloth allows for complete customization of filter cloths. Whether you need small perforations, specific shapes, or detailed designs, laser cutting filter cloth can easily accommodate your needs, giving you the flexibility to produce a wide range of filter cloth products.

5. No Tool Wear

Unlike die-cutting or mechanical cutting, laser cutting filter cloth does not involve physical contact with the material, meaning there is no wear on blades or tools. This reduces maintenance costs and downtime, making it a more reliable long-term solution.

• Working Area (W *L): 1000mm * 600mm

• Laser Power: 60W/80W/100W

• Working Area (W *L): 1300mm * 900mm

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

• Laser Power: 100W/150W/300W

In Conclusion

Laser cutting filter cloth has proven to be an excellent method for cutting filter cloths, offering numerous advantages such as precision, speed, and minimal waste. Whether you’re cutting polyester, foam, nylon, or nonwoven fabrics, laser cutting filter cloth ensures high-quality results with sealed edges and customized designs. MimoWork Laser’s range of filter cloth laser cutting systems provides the perfect solution for businesses of all sizes looking to optimize their filter cloth production process.

Contact us today to learn more about how our filter cloth laser cutting machines can enhance your filter cloth cutting operations and improve the quality of your products.

When it comes to selecting a filter cloth laser cutting machine, consider the following:

Types of Machines:

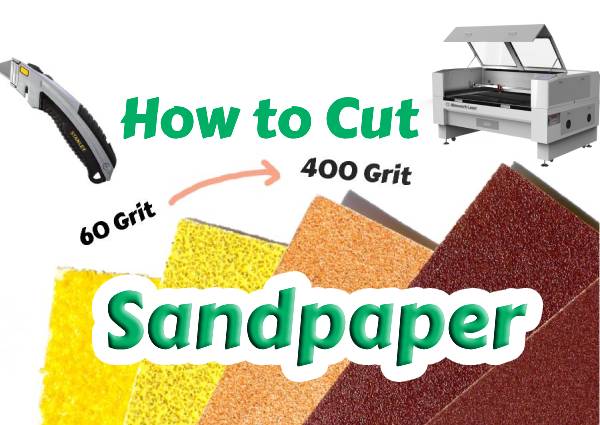

CO2 laser cutters are generally recommended for cutting filter cloth because the laser can cut various shapes and sizes. You need to choose a suitable laser machine size and power according to your material types and features. Consult a laser expert for professional laser advice.

Test is First:

Before you invest in a laser cutting machine, the best method is to make a material test using the laser. You can use a scrap of filter cloth and try different laser powers and speeds to check out the cutting effect.

Any Ideas about Laser Cutting Filter Cloth, Welcome to Discuss with Us!

Any Questions about Laser Cutting Machine for Filter Cloth?

Post time: Nov-14-2024