Understanding Laser Cut Velcro:

Innovations in Adhesive Technology

What is Velcro? The Foundation of Laser Cut Velcro

Velcro, a trademarked name for a type of hook-and-loop fastener, revolutionized fastening mechanisms when it was invented in the 1940s by Swiss engineer George de Mestral.

The concept was inspired by nature; de Mestral noticed how burrs clung to his dog’s fur during a hike.

This led to the creation of a two-part system: one strip features tiny, stiff hooks, while the other is composed of soft loops.

When the two sides are pressed together, the hooks catch onto the loops, creating a strong bond that can be easily separated with a simple tug.

Laser Cut Velcro

This ingenious mechanism has since permeated various sectors, from fashion to industrial applications, showcasing its versatility and practicality.

Table of Content:

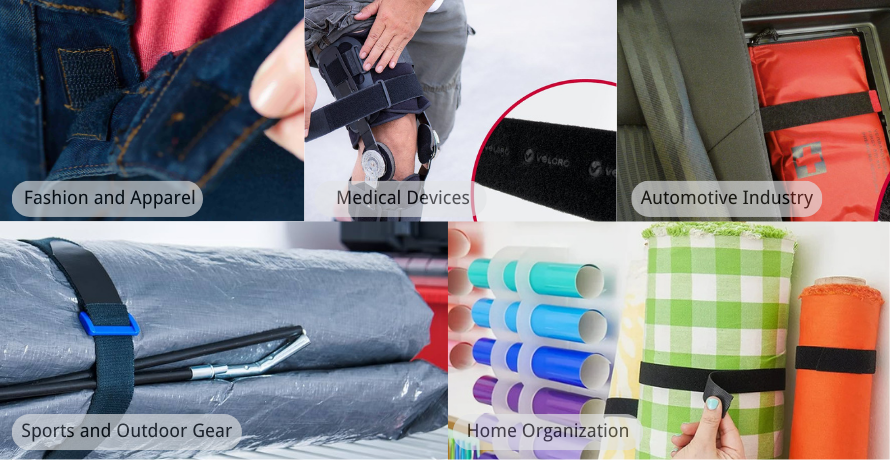

Typical Application Segments of Velcro: Where Laser Cut Velcro Shines

1. Fashion and Apparel

In the fashion industry, Velcro is commonly used in shoes, jackets, bags, and various accessories.

For example, thin Velcro can be applied to the back of petite enamel pins, making them easy to attach and remove.

Its convenience is especially appealing for children’s clothing and footwear, where quick fastening or adjustment is often needed.

Compared with traditional closures like buttons and zippers, Velcro not only improves functionality but also provides greater design flexibility.

Designers can incorporate Velcro into innovative styles without compromising comfort or wearability.

2. Medical Devices

The healthcare sector benefits immensely from Velcro's adjustable nature.

Medical braces, bandages, and support garments often employ Velcro fasteners for easy adjustments, ensuring a snug fit for patients.

This adaptability is crucial in medical settings, where comfort and functionality are paramount.

For example, Velcro is used in prosthetics to secure the device comfortably to the wearer’s body, allowing for personalized adjustments.

3. Automotive Industry

In the automotive field, Velcro is utilized for securing various components within vehicles.

Such as floor mats, headliners, and even electronic devices like dashboard panels.

Its lightweight nature can contribute to overall vehicle efficiency.

While its ability to be easily removed and reattached facilitates maintenance and repairs.

4. Sports and Outdoor Gear

Sports equipment manufacturers often integrate Velcro into helmets, pads, and other protective gear.

The quick-release feature allows athletes to make on-the-fly adjustments during activities.

Additionally, Velcro is used in backpacks and outdoor gear, providing secure closures that are easy to operate even in challenging conditions.

Such as while wearing gloves.

Various Applications for Laser Cut Velcro

5. Home Organization

Velcro is a popular choice for home organization solutions.

It can secure curtains, hold rugs in place, and organize cables.

Offering a simple yet effective way to declutter living spaces.

Its ease of use makes it an ideal solution for DIY enthusiasts looking to enhance their home’s functionality.

Find Out Whether Laser Cutting Velcro

Is Suitable for Your Region and Industry

Benefits of Laser Cut Velcro: Why Choose This Advanced Fastening Solution?

1. Precision and Customization

Laser cutting technology is capable of producing intricate designs with high precision.

This means that manufacturers can create custom shapes, sizes, and patterns tailored to specific applications.

For instance, in the fashion industry, designers can experiment with unique cutouts and shapes that enhance the aesthetic appeal of their products.

In the medical field, custom sizes ensure a better fit for devices, improving patient comfort.

2. Enhanced Durability

One of the standout advantages of laser cutting is its ability to produce clean edges.

Traditional cutting methods can leave frayed edges, which compromise the longevity of the Velcro.

Laser-cut edges are sealed during the cutting process, reducing wear and tear, and enhancing the overall durability.

This characteristic is particularly important in industrial applications where Velcro may be subjected to harsh conditions.

3. Automotive Industry

Laser cutting is known for its efficiency.

Traditional cutting methods often result in considerable material waste due to the size and shape of the cut pieces.

In contrast, laser cutting minimizes waste by closely nesting pieces together, ensuring that more of the material is utilized.

This not only lowers production costs but also contributes to environmental sustainability—a growing concern in today’s manufacturing landscape.

4. Quick Turnaround Times

With the speed and efficiency of laser cutting technology, manufacturers can produce large quantities of Velcro in a shorter timeframe.

This is particularly beneficial for industries with fluctuating demand or tight deadlines, allowing for quick responses to market changes.

The ability to rapidly prototype custom designs also fosters innovation, as companies can test new ideas without lengthy production times.

5. Cost-Effectiveness

Laser cutting technology can lead to lower production costs over time.

Although the initial investment in laser cutting equipment can be significant, the long-term savings from reduced material waste.

Lower labor costs, and faster production times can make it an economical choice for manufacturers.

This cost-effectiveness allows businesses to offer competitive pricing while maintaining high-quality products.

A Batch of Laser Cut Velcro

6. Versatility in Materials

Laser cutting can be applied to a wide range of materials beyond traditional Velcro fabric.

This includes specialty fabrics, composites, and even advanced textiles embedded with electronic components.

The versatility of laser technology opens up new possibilities for innovation, enabling the creation of smart Velcro that could integrate sensors or other functionalities.

7. Improved Aesthetics

Laser cut Velcro can also enhance the visual appeal of products.

With the ability to create intricate designs, manufacturers can produce Velcro that not only serves a functional purpose but also adds to the product's overall aesthetic.

This is particularly advantageous in fashion and home decor, where appearance is as important as functionality.

Discover the power of laser cutting for sublimation on polyester!

Watch as we transform fabrics into vibrant, customized designs, packed with tips and inspiration for DIY enthusiasts and pros alike.

Dive into the future of fabric processing with our Automated Laser Textile Cutting video!

Witness how advanced laser technology streamlines cutting, enhancing precision and efficiency in textile production.

Perfect for designers and manufacturers, this video showcases the benefits and innovations of automated cutting in the fashion industry.

Best 100W Laser Cutter to be Upgraded to

This customizable laser cutting machine features a 100W laser tube, perfect for local workshops and growing businesses.

It efficiently handles a variety of cutting tasks on solid materials like wood and acrylic, enhancing production diversity.

For information on upgrades and custom options, feel free to reach out anytime.

Unleash Your Creativity with 300W to Boost

Introducing the 300W Laser Cutter, a versatile and customizable machine perfect for your budget.

Ideal for cutting and engraving wood and acrylic, it features a powerful 300W CO2 laser tube for thick materials.

With a two-way penetration design for added flexibility and an optional DC brushless servo motor for speeds up to 2000mm/s, this cutter meets all your specific needs.

Can You Laser Cut Nylon (Lightweight Fabric)?

We Tested with 1630 Fabric Laser Cutter

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Jan-15-2025