Enhance Koozie Appearance with Laser Processing

Upgrade Koozies Production

In today’s market, custom can koozies are more popular than ever, offering a personalized touch for events, promotions, and everyday use. By utilizing laser processing - laser cutting and laser engraving, you can achieve high-quality, tailor-made koozies that stand out. Whether it's a one-off custom order or a large batch for corporate branding, laser technology ensures precision and efficiency in production.

1. What is Koozie?

A koozie, also known as a beverage holder or drink sleeve, is a popular accessory designed to keep beverages cold while providing a comfortable grip.

Typically made from neoprene or foam, koozies are widely used at parties, picnics, and outdoor events, making them a staple for both personal and promotional use.

Koozies serve various purposes, ranging from personal enjoyment to effective marketing tools. They can be customized for special events like weddings, birthdays, and corporate gatherings, providing a practical solution for keeping drinks cold while doubling as promotional items. Many businesses utilize koozies as giveaways, enhancing brand visibility while adding a touch of personalization to their marketing efforts.

3. CO2 Laser Compatibility with Koozie Materials

With advancements in laser cutting and engraving technology, the production of koozies is set to undergo an exciting transformation. Here are a few innovative applications:

Materials like foam and neoprene, commonly used in koozie production, are highly compatible with CO2 laser cutting and engraving. This method allows for clean, precise cuts without damaging the material, and also offers the ability to engrave logos, patterns, or text directly onto the surface. This makes laser processing ideal for producing custom designs that maintain durability and aesthetic appeal.

• Laser Cutting Custom Koozies

Utilizing laser cutting technology, producers can achieve precise shapes and custom designs that stand out in the market. Laser cutting koozie ensures clean edges and consistent quality, allowing for unique branding opportunities and creative designs that cater to specific customer needs.

Besides, there is no die cutter, no consumables during laser cutting koozies. It's an economic and highly efficient processing method. With the help of laser cutting, you can start custom or mass production, quickly responding to the market trend.

• Laser Cutting Sublimation Koozies

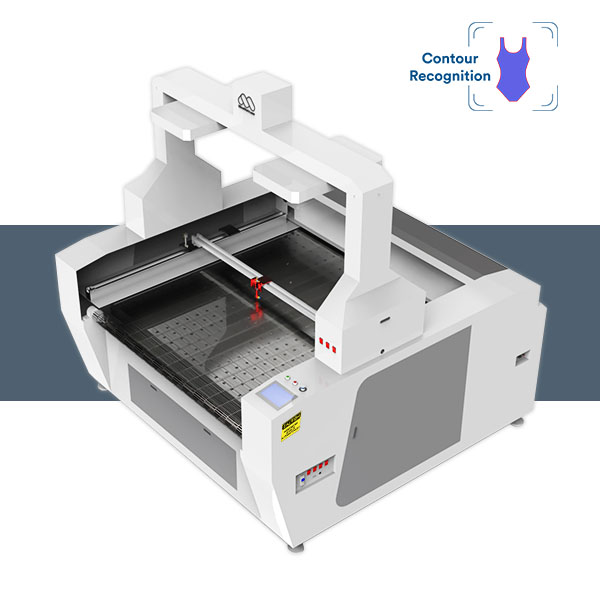

For sublimation-printed koozies, laser cutting machines equipped with a camera provide an extra level of accuracy.

The camera recognizes printed patterns and aligns the cutting process accordingly, ensuring that the laser cutter precisely follows the contour of the design.

This advanced technology results in perfectly cut koozies with smooth edges, offering both aesthetic and functional advantages.

• Laser Engraving Koozies

Laser engraving offers a refined way to personalize koozies.

Whether for corporate gifts, wedding favors, or special events, laser engraving provides a classy touch that adds value to the product.

Custom logos or messages can be elegantly etched into the material, ensuring long-lasting impressions.

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Laser Tube: CO2 Glass or RF Metal Laser Tube

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2,000mm/s

• Working Area: 1600mm * 1200mm (62.9” * 47.2”)

• Laser Power: 100W / 130W / 150W

• Laser Software: CCD Camera System

• Laser Tube: CO2 Glass or RF Metal Laser Tube

• Max Cutting Speed: 400mm/s

• Working Table: Conveyor Table

If you are interested in the laser machine for koozies, talk with us for more advice!

Conclusion

The integration of laser cutting and engraving technology into koozie production opens up a world of possibilities for manufacturers and consumers alike. By upgrading the production process, businesses can enhance the aesthetic appeal of koozies while providing consumers with personalized, high-quality products. As the demand for custom merchandise continues to grow, investing in laser technology will empower producers to meet these evolving market needs and drive innovation in the beverage accessory industry.

5. FAQ of Laser Etching Leather

1. Is neoprene safe to laser cut?

Yes, neoprene is generally safe to laser cut, especially with a CO2 laser, which is well-suited for this material.

However, it’s important to ensure the neoprene is chlorine-free, as chlorine-containing materials can release harmful gases during the cutting process. We suggest you equip a fume extractor for your laser cutting machine, that can effectively purify and clear away the fumes. Always follow safety guidelines, use proper ventilation, and consult the material's safety data sheet (SDS) before cutting.

More information about that, you can check out the page: Can You Laser Cut Neoprene

2. Can you laser engrave neoprene koozies?

Yes, neoprene koozies can be laser engraved using a CO2 laser. Laser engraving on neoprene creates precise, clean marks that are perfect for custom designs, logos, or text. The process is quick and efficient, offering a durable and personalized finish without damaging the material. Laser engraving adds a stylish, professional touch to koozies, making them ideal for promotional items or personal gifts.

Related Links

If you have any questions about laser cutting koozies, talk with us!

You may be Interested

About cutting foam, you may be familiar with hot wire(hot knife), water jet, and some traditional processing methods.

But if you want to get higher precise and customized foam products like toolboxes, sound-absorbing lampshades, and foam interior decoration, the laser cutter must be the best tool.

Laser cutting foam provides more convenience and flexible processing on a changeable production scale.

What is a foam laser cutter? What is laser cutting foam? Why you should choose a laser cutter to cut foam?

Laser engraved leather is the new fashion in leather projects!

Intricate engraved details, flexible and customized pattern engraving, and super fast engraving speed definitely surprise you!

Only need one laser engraver machine, no need for any dies, no need for knife bits, the leather engraving process can be realized at a fast speed.

Therefore, laser engraving leather not only greatly increases productivity for leather products manufacturing, but also is a flexible DIY tool to meet all kinds of creative ideas for hobbyists.

Laser engraving stone is a powerful way to create intricate and lasting designs on natural materials.

For example, laser engraving a stone coaster allows you to etch detailed patterns, logos, or text onto the surface with precision. The laser's high heat removes the top layer of the stone, leaving behind a permanent, clean engraving. Stone coasters, being sturdy and natural, offer an ideal canvas for personalized and decorative designs, making them popular as gifts or custom items for homes and businesses.

Get One Laser Etching Machine for Your Koozies Business or Design?

Post time: Oct-14-2024