Laser Cutting:Choosing The Right File Format

Introduction:

Key Things To Know Before Diving In

Laser cutting is a precise and versatile manufacturing process that utilizes various types of laser cutters to create intricate designs and patterns on materials such as wood, metal, and acrylic. To achieve optimal results, it is crucial to understand what file does laser cutter use, as the choice of file format directly impacts the quality and accuracy of the laser cut. Common file formats used in laser cutting include vector-based formats like the SVG file format, which is widely preferred for its scalability and compatibility with most laser cutting software. Other formats such as DXF and AI are also popular, depending on the specific requirements of the project and the types of laser cutters being used. Selecting the right file format ensures that the design is accurately translated into a clean and precise laser cut, making it an essential consideration for anyone involved in laser cutting projects.

Types Of Laser Cutting Files

Laser cutting requires specific file formats to ensure precision and compatibility with the machine. Here’s a quick overview of the most common types:

▶ Vector Files

A vector file is a graphic file format defined by mathematical formulas such as points, lines, curves, and polygons. Unlike bitmap files, vector files can be infinitely enlarged or reduced without distortion because their images are composed of paths and geometric shapes, not pixels.

• SVG (Scalable Vector Graphics): This format allows infinite resizing without affecting image clarity or laser cutting results.

• CDR (CorelDRAW File): This format can be used to create images through CorelDRAW or other Corel applications.

• Adobe Illustrator (AI): Adobe Illustrator is a popular tool for creating vector files, known for its ease of use and powerful features, often used for designing logos and graphics.

▶ Bitmap Files

Raster files (also known as bitmaps) are made up of pixels, used to create images for computer screens or paper. This means resolution affects clarity. Enlarging a raster image reduces its resolution, making it more suitable for laser engraving rather than cutting.

• BMP (Bitmap Image): A common raster file for laser engraving, acting as a "map" for the laser machine. However, output quality may degrade depending on resolution.

• JPEG (Joint Photographic Experts Group): The most widely used image format, but compression reduces quality.

• GIF (Graphics Interchange Format): Originally used for animated images, but can also be used for laser engraving.

• TIFF (Tagged Image File Format): Supports Adobe Photoshop and is the best raster file format due to its low-loss compression, popular in commercial printing.

• PNG (Portable Network Graphics): Better than GIF, offering 48-bit color and higher resolution.

▶ CAD And 3D Files

CAD files enable the creation of complex 2D and 3D designs for laser cutting. They are similar to vector files in quality and mathematical formulas but are more technical due to their support for intricate designs.

SVG(Scalable Vector Graphics)

• Features: XML-based vector graphics format that supports scaling without distortion.

• Applicable scenarios: suitable for simple graphics and web design, compatible with some laser cutting software.

DWG(Drawing)

• Features: Native file format of AutoCAD, support for 2D and 3D design.

• Suitable for use cases: Commonly used in complex designs, but need to be converted to DXF to be compatible with laser cutters.

▶ CAD And 3D Files

Compound files are more complex than raster and vector file formats.With compound files, you can store raster and vector images. This makes it a unique choice for users.

• PDF (Portable Document Format) is a versatile file format widely used for sharing documents due to its ability to preserve formatting across different devices and platforms.

• EPS (Encapsulated PostScript) is a vector graphics file format widely used in graphic design and printing.

File Format Selection And Advantages

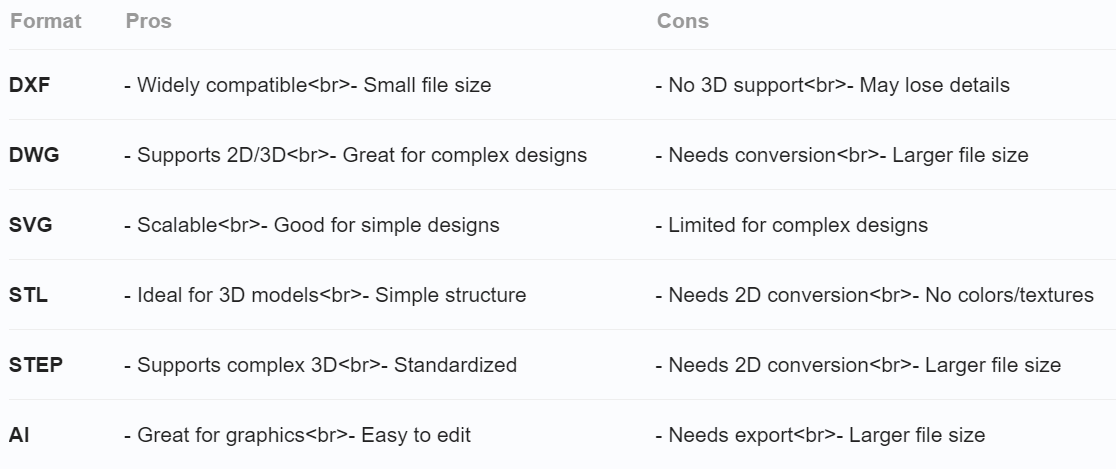

▶ Pros And Cons Of Different Formats

▶ Relationship Between File Resolution And Cutting Precision

• What Is File Resolution?

File resolution refers to the density of pixels (for raster files) or the level of detail in vector paths (for vector files). It is typically measured in DPI (dots per inch) or PPI (pixels per inch).

Raster Files: Higher resolution means more pixels per inch, resulting in finer detail.

Vector Files: Resolution is less critical as they are based on mathematical paths, but the smoothness of curves and lines depends on the precision of the design.

▶ Impact Of Resolution On Cutting Precision

• For Raster Files:

High Resolution: Provides finer details, making it suitable for laser engraving where intricate designs are required. However, excessive resolution can increase file size and processing time without significant benefits.

Low Resolution: Results in pixelation and loss of detail, making it unsuitable for precise cutting or engraving.

• For Vector Files:

High Precision: Vector files are ideal for laser cutting as they define clean, scalable paths. The resolution of the laser cutter itself (e.g., laser beam width) determines the cutting precision, not the file resolution.

Low Precision: Poorly designed vector paths (e.g., jagged lines or overlapping shapes) can lead to inaccuracies in cutting.

▶ File Conversion And Editing Tools

File conversion and editing tools are essential for preparing designs for laser cutting. These tools ensure compatibility with laser cutting machines and optimize designs for precision and efficiency.

• Editing Tools

These tools allow users to modify and optimize designs for laser cutting.

Popular Tools:

- LaserCut Software

- LightBurn

- Fusion 360

Key Features:

- Clean up and simplify designs for better cutting results.

- Add or modify cutting paths and engraving areas.

- Simulate the cutting process to identify potential issues.

• File Conversion Tools

These tools help convert designs into formats compatible with laser cutters, such as DXF, SVG, or AI.

Popular Tools:

- Inkscape

- Adobe Illustrator

- AutoCAD

- CorelDRAW

Key Features:

- Convert raster images to vector formats.

- Adjust design elements for laser cutting (e.g., line thickness, paths).

- Ensure compatibility with laser cutting software.

▶ Tips For Using Conversion And Editing Tools

✓ Check File Compatibility: Ensure the output format is supported by your laser cutter.

✓ Optimize Designs: Simplify complex designs to reduce cutting time and material waste.

✓ Test Before Cutting: Use simulation tools to verify the design and settings.

Laser Cutting File Creation Process

There are several steps involved in creating a laser-cut file to ensure that the design is accurate, compatible, and optimized for the cutting process.

▶ Selection Of Design Software

Options: AutoCAD, CorelDRAW, Adobe Illustrator, Inkscape.

Key: Choose software that supports vector designs and exports DXF/SVG.

▶ Design Standards And Considerations

Standards: Use clean vector paths, set line thickness to "hairline," account for kerf.

Considerations: Adapt designs for material type, simplify complexity, ensure safety.

▶ File Export And Compatibility Check

Export: Save as DXF/SVG, organize layers, ensure correct scaling.

Check: Verify compatibility with laser software, validate paths, test on scrap material.

Summary

Select the right software, follow design standards, and ensure file compatibility for precise laser cutting.

FLAWED Perfection | LightBurn Software

LightBurn Software is perfect for Laser Engraving Machine. From Laser Cutting Machine to Laser Engraver Machine, LightBurn has been perfect. But even perfection has its flaws, in this video, you might learn something you would never know about LightBurn, from its documentation to compatibility issues.

Any Ideas about Laser Cutting Felt, Welcome to Discuss with Us!

Common Problems And Solutions

▶ Reasons For File Import Failure

Sol Incorrect File Format: The file is not in a supported format (e.g., DXF, SVG).

Corrupted File: The file is damaged or incomplete.

Software Limitations: The laser cutting software cannot process complex designs or large files.

Version Mismatch: The file was created in a newer version of the software than the laser cutter supports.

▶ Utions for Unsatisfactory Cutting Results

Check Design: Ensure vector paths are clean and continuous.

Adjust Settings: Optimize laser power, speed, and focus for the material.

Test Cuts: Perform test runs on scrap material to fine-tune settings.

Material Issues: Verify material quality and thickness.

▶ File Compatibility Issues

Convert Formats: Use tools like Inkscape or Adobe Illustrator to convert files to DXF/SVG.

Simplify Designs: Reduce complexity to avoid software limitations.

Update Software: Ensure the laser cutting software is up-to-date.

Check Layers: Organize cutting and engraving paths into separate layers.

Any Questions About Laser Cutting File Format?

Post time: Mar-07-2025