Why Do You Choose A Handheld Laser Welder?

Handheld Laser Welding Machine - Leading The Industry New Wind

A hand-held laser - sounds like a cool piece of equipment, doesn't it? In today's fast-paced manufacturing environment. The need for efficient and effective welding solutions has never been more important.

So, compared with the traditional laser welding machine. What makes the handheld laser welding machine stand out?

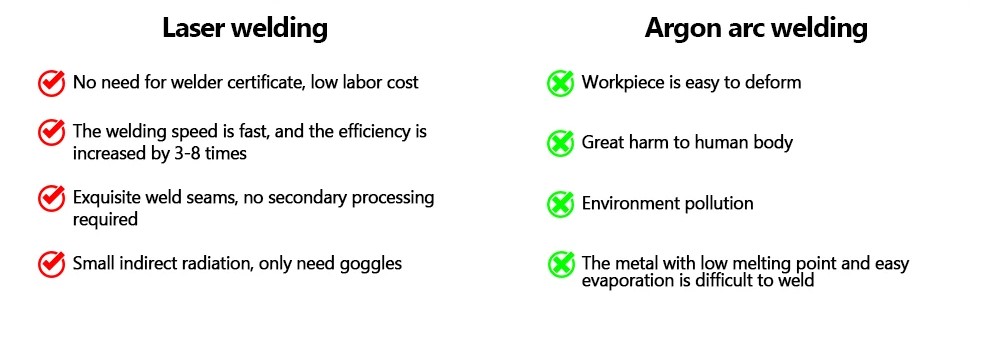

Let me introduce you to the advantages of handheld laser welders compared to traditional welding methods.

And how handheld laser welders actually bring some enlightenment.

Table of Content:

What Is A Handheld Laser Machine?

It's a welding method with high efficiency, excellent quality and low cost.

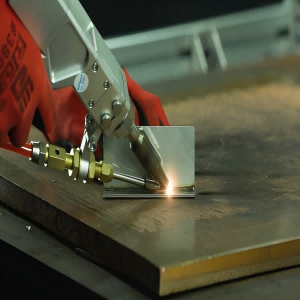

The handheld laser machine is a kind of convenient hand-held operation.

The core of which is to use the laser beam to make permanent marks on the surface of the object.

This is a method of high efficiency, high quality and low cost.

Surprisingly, traditional welding methods (such as MIG or TIG) are rough to process.

While the beam of the handheld laser has a very small focusing diameter.

Enabling micron-level marking accuracy to ensure that the marking content is clearer.

Not long ago, I was helping out at a factory that made custom welded parts.

One of the most challenging tasks we encountered was how to join the thin pieces of aluminum together under excessive heat.

When we switched to a handheld laser welder.

We found that it produced high quality welds with minimal thermal shock.

Greatly reducing the risk of warping and ensuring the cleanliness of the weld without the need for extensive post-weld finishing.

It's a pretty cool thing, isn't it?

Comparing With Traditional Laser Welding Machine

Hand-held welding machines are superior

In recent years, countries worldwide have had higher and higher requirements for environmental protection.

Argon arc welding will produce a large amount of welding dust and slag.

It is extremely harmful to the environment.

Companies that fail to meet environmental protection requirements will face regulatory oversight.

And laser hand-held welding is relatively less harmful to the environment.

It can be widely used in some irregular and complicated industries.

Traditional Argon Arc Welding Introduction

Advantages

1. Traditional argon arc welding also has a comparative advantage. The price is low, generally ranging from a few thousand to 20,000 to 30,000.

2. Although the processing is relatively rough, the power is stronger than others. It is suitable for load-bearing steel structures with slow welding speeds.

Disadvantages

1. The welding thickness is relatively thick, suitable for thick welding plates above 4mm.

2. Argon arc welding requires mature welders. And the monthly salary of mature welders starts at least 8K.

Handheld Laser Welding Introduction

Advantages

1. The complete set of handheld laser welding equipment is powerful. Ergonomically designed and suitable for various working environments. It has a unique laser safety operation protection function. And it can ensure the operator’s safety when working.

2. The operation is easy to learn and quick to use. And the technical threshold of the operator is not high, which saves labor costs.

3. Hand-held welding is easy to learn. Ordinary operators can get started in half a day. The monthly salary of an ordinary handheld welder is generally around 4k.

4. The speed of a laser welding machine is 10-20 times. Ordinary laser workers can easily operate it, and the working environment is relaxed. The salary of one argon arc welder can employ three laser operators.

Choose a different type of handheld laser welding machine?

We Can Help Make the Right Decision Based on Applications

Advantages of Hand Held Laser Welders

There are some Real Perks to Using handheld laser welding

The final product of hand-held laser welding is spotless and requires no sanding or rework.

Hand-held welding not only meets this standard, but also exceeds it.

Enhanced Aesthetic Appearance

Hand held laser welders produce products with superior visual quality.

The stable beam quality ensures strong, smooth, and attractive weld seams, minimizing deformation and welding scars.

This reduces the need for secondary polishing, saving time and lowering labor costs for manufacturers.

High Speed and Increased Production Efficiency

Laser welding is significantly faster than traditional methods, with speeds that can reach 5 to 10 times faster.

The ability to maintain a deep penetration and high yield rate across different materials enhances productivity.

Continuous operation is supported by dedicated cooling systems, allowing for 24-hour workflow

Low Heat Consumption

The laser welding process creates a small heat-affected zone, minimizing thermal damage to surrounding materials.

This precision ensures clean welds and preserves the integrity of the product, reducing the risk of warping.

Cleaner Welds

The welds typically come out cleaner, needing less post-processing.

In industries where the appearance of the final product is as important as its strength (think automotive or aerospace), this is a huge advantage.

Hand-held laser welding machine simplifies

the production process!

Handheld Laser Welder Applicable Working Conditions

Hand-held Laser Welding Is , It’s Not Without Its Considerations

Although the advantages of handheld laser welding machines are very large.

There are also some precautions.

First, the equipment is expensive and requires a certain amount of learning time to use and maintain properly.

Also, many customers who intend to introduce a handheld laser welding machine.

Who have concerns about its use and performance.

Some customers have used it for some time and summarized the following content.

Handheld Laser Welding Machines

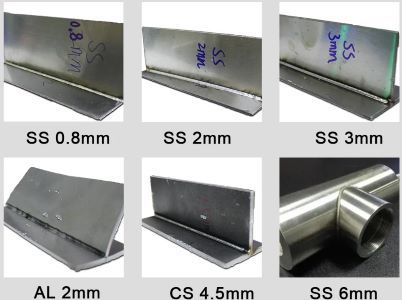

The Handheld Laser Welding Machine is Suitable for the Following Working Conditions:

· Large welding area requires high welding efficiency.

· The thickness of the plate is above 0.5mm.

· Solve the problem of weld beauty and deformation.

· Mainly made of stainless steel, iron plate, and aluminum.

· There is a certain amount of budget space.

· To solve the labor problem, the handheld laser welder can start working with zero welding foundations.

How Thick Can Laser Welding Machine Weld?

The greater the thickness of the welded workpiece, the greater the power of the selected laser welding machine should be.

1. 1000W laser welder machine: the welding effect is good for plates with a thickness of less than 3mm.

2. 1500W laser welder machine: the welding effect is good for plates with a thickness of less than 5mm.

3. 2000W laser welder machine: the welding effect is good for plates with a thickness of less than 8mm.

You need to know: How to choose a handheld laser machine

High-Capacity & Wattage for Various Welding Applications

The 2000W handheld laser welding machine is characterized by small machine size but sparkling welding quality.

A stable fiber laser source and connected fiber cable provide a safe and steady laser beam delivery.

With the high power, the laser welding keyhole is perfectible and enables the welding joint firmer even for thick metal.

Portability for Flexibility

With a compact and small machine appearance, the portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight and convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles and automatic wire feeding systems make laser welding operation easier and that is friendly for beginners.

High-speed laser welding greatly increases your production efficiency and output while enabling an excellent laser welding effect.

Things You NEED to Know about: Handheld Laser Welding

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Jan-13-2025