Why Should You Choose Laser Etching Leather?

Customization, Precision, Efficiency

Laser etching leather has become an essential tool for businesses and artisans, offering unmatched precision and customization. Whether you're working on laser-etched leather patches or personalizing leather accessories, the benefits of using a leather laser etching machine are countless. Here’s why you should choose laser etching on leather for your next project.

1. Unmatched Precision and Detail

We know there are many methods to etch and engrave your leather items, such as stamping and embossing, knife carving, laser etching, burning, and CNC engraving, they are great in some aspects. But when it comes to precision and richness of details and patterns, laser etching is undoubtedly the No.1.

Super high precision and the digital control system from the professional leather laser etching machine, offer a superfine laser beam impacting on the leather with 0.5mm diameters.

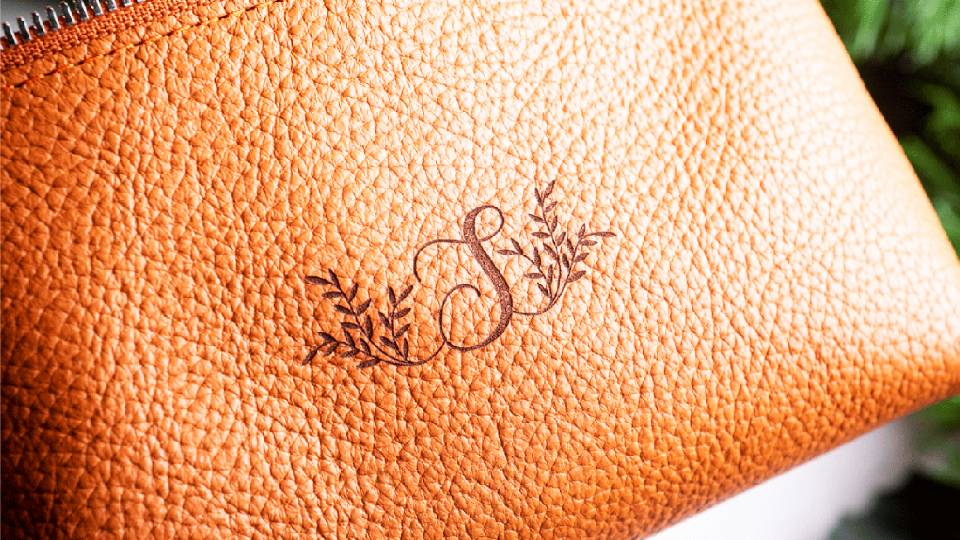

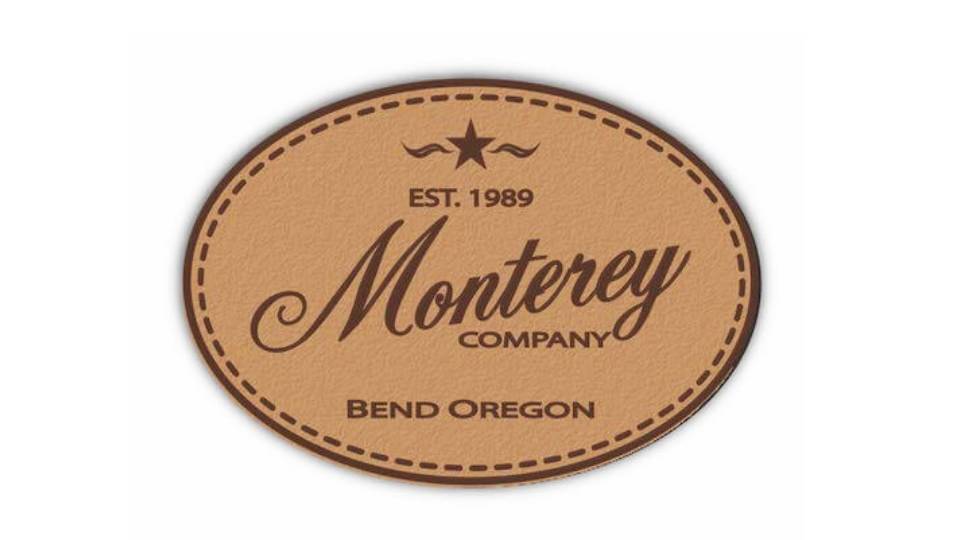

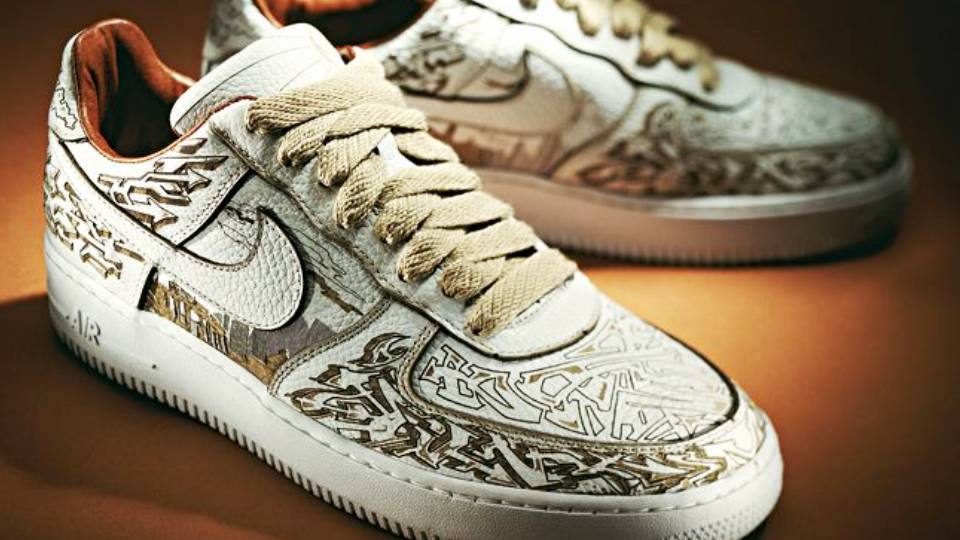

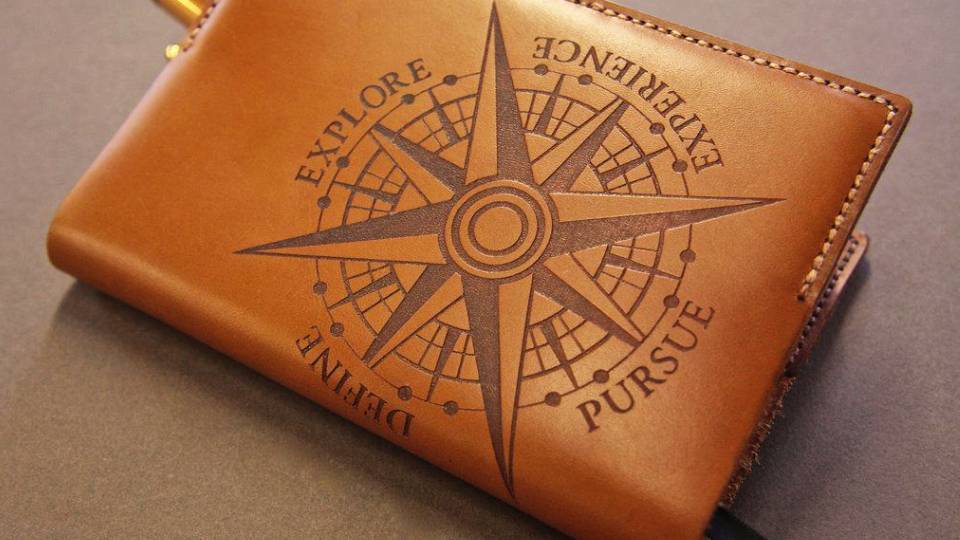

You can use the advantage to engrave exquisite and intricate patterns on your leather items like wallets, bags, patches, jackets, shoes, crafts, etc.

With laser etching leather, you can achieve an extraordinary level of precision. The laser beam can engrave intricate patterns and designs, resulting in highly detailed laser-etched leather products.

This makes laser etch leather perfect for creating custom artwork, branding, or patterns on leather goods.

Example: Custom logos and intricate patterns engraved on wallets or belts.

Use case: Businesses that need to add precise logos on laser-etched leather patches for branding.

2. Customization at Scale

One of the best things about laser etching on leather is the ability to easily switch between different designs without additional tooling. This allows for complete customization, whether you're working on a single item or mass-producing leather goods.

The flexible customization of laser etching leather, on the one hand, comes from the fine laser beam, it is like a dot, and can draw any pattern including vector and pixel graphics, leaving engraved or etched marks of unique style.

On the other hand, it comes from the adjustable laser power and speed, these parameters determine the leather etching depth and space, and affect your leather styles.

For example, if you use a 100W leather laser etching machine, and set the laser power to 10%-20%, you can get a light and shallow engraving or marking on the leather surface. That suits engraving logos, letters, text, and greeting words.

If you increase the power percentage, you will get a deeper etching mark, that is more vintage, like stamping and embossing.

Last but not least, the friendly laser engraving software is editable at any time, if you test your design on a piece of leather scrap and it's not ideal, you can modify the design graphic in the software, and then go testing until you get a perfect effect.

The whole laser leather etching is flexible and customized, suitable for independent designers and those who do tailor-made business.

Benefit: Allows businesses to offer personalized leather products without additional setup costs.

Example: Offering laser-etched leather patches on custom jackets and bags for a personalized touch.

Video Display: 3 Tools of Etching Leather

3. Versatility Across Applications

Laser etching is suitable for most leather products and leather types including vegetable-tanned leather, nubuck, full-grain leather, PU leather, suede, and even Alcantara similar with leather.

Among the many lasers, the CO2 laser is most suitable and it can create graceful and delicate laser-etched leather.

Laser etching machines for leather are versatile and can be used on various leather products.

Besides the daily leather crafts, leather patches, gloves, and protective gear, laser etching leather can be used in automotive fields such as laser etching brand name on the steering wheel, laser marking patterns on the seat cover.

By the way, the laser can cut holes even micro holes in the leather seat cover to add breathability and appearance. More about what can you do with laser etching leather, go into the news to find out: laser engraving leather ideas

Some Laser Etched Leather Ideas >>

4. High Speed and Efficiency

The laser etching machine for leather delivers both speed and accuracy, making it ideal for businesses with large production needs.

With the right setting and operation, the professional Galvo leather laser engraver can reach the marking speed between 1 and 10,000mm/s. And if your leather is in roll, we recommend you to choose the leather laser machine with the auto-feeder and conveyor table, that are helpful to speed up the production.

Whether you need to create one-off pieces or mass-produce items, the laser etch leather process ensures fast production times without compromising quality.

Video Demo: Fast Laser Cutting & Engraving on Leather Shoes

Benefit: Perfect for businesses looking to produce large quantities of laser-etched leather items quickly.

Example: Fast production of leather belts and accessories with custom engravings.

5. Environmentally Friendly

Unlike traditional engraving methods, laser etching machines for leather do not require physical contact, chemicals, or dyes. This makes the process more sustainable and eco-friendly, with less waste generated.

Impact: More sustainable leather production with minimal environmental impact.

Benefit: Eco-conscious businesses can align their practices with environmentally friendly processes.

6. Durable and Long-Lasting Designs

The designs produced by laser etching leather are durable and resistant to wear. Whether it's for leather patches or detailed engravings on leather goods, laser-etched leather ensures that the designs will last over time, even with continuous use.

Interested in the laser etching leather?

The following laser machine would be helpful to you!

• Working Area: 400mm * 400mm (15.7” * 15.7”)

• Laser Power: 180W/250W/500W

• Laser Tube: CO2 RF Metal Laser Tube

• Max Cutting Speed: 1000mm/s

• Max Engraving Speed: 10,000mm/s

• Working Area: 1600mm * 1000mm (62.9” * 39.3 ”)

• Laser Power: 100W/150W/300W

• Max Cutting Speed: 400mm/s

• Working Table: Conveyor Table

• Mechanical Control System: Belt Transmission & Step Motor Drive

FAQ of Laser Etching Leather

1. What is the best leather for laser engraving?

The best leather for laser etching is vegetable-tanned leather due to its natural, untreated surface that responds well to etching. It produces clean, precise results without excessive burn marks.

Other good options include chrome-tanned leather and suede, but they may require more careful settings to avoid undesirable effects like discoloration or burning. Avoid heavily treated or synthetic leathers as they may emit harmful fumes and can result in uneven etching.

Testing on scrap pieces is always recommended to fine-tune your settings.

2. Which laser is suitable leather etching and engraving?

CO2 laser and diode laser are capable of engraving and etching leather. But there are differences on engraving effect due to their machine performance and potential.

CO2 laser machine is more strong and hardworking, it can handle deeper leather engraving on one pass. Obviously, CO2 laser etching leather machine comes with higher production efficiency and various engraving effects. But it has a bit higher cost than diode laser.

Diode laser machine is smaller, it can deal with thin leather craft with light engraving and etching marks, if you want to get a deeper engraving, there is no way but to work multiple passes. And due to its small working area and low power, it can not meet the production of industry-grade and high efficiency. production

Suggestion

For Professional Use: A CO2 laser in the 100W-150W range is ideal for leather etching and engraving. This will give you the best combination of precision and efficiency.

For Hobbyists or Small Projects: A low-power CO2 laser (around 40W-80W) or a diode laser can work for lighter engraving tasks.

3. How to set laser etching leather?

• Power: Generally lower than cutting. Start with about 20-50% power, depending on your laser machine and the engraving depth you want.

• Speed: Slower speeds allow for deeper etching. A good starting point is around 100-300 mm/s. Again, adjust based on your tests and desired depth.

• DPI: Setting a higher DPI (around 300-600 DPI) can help achieve more detailed etching, especially for intricate designs. But it's not for every situation, specific setting please consult a professional laser expert.

• Focus the Laser: Make sure the laser is properly focused on the leather surface for clean etching. For detailed guide, you can check out the article about how to find the right focal length.

• Leather Placement: Secure the leather on the laser bed to prevent movement during the etching process.

4. What is the difference between laser engraving and embossing leather?

• Laser Engraving is a process where a laser beam burns or vaporizes the surface of the leather to create permanent, precise markings. This method allows for detailed designs, including fine text, intricate patterns, or images. The result is a smooth, indented marking on the leather’s surface.

• Embossing involves pressing a heated die or stamp into the leather, which creates a raised or recessed design. This is done mechanically, and the effect is more three-dimensional. Embossing typically covers larger areas of the leather and can create a more tactile texture, but it does not allow for the same level of precision as laser engraving.

5. How to operate the leather laser etching machine?

It's easy to operate the laser machine. CNC system give it high automation. You just need to complete the three steps, and for others the laser machine can finish them.

Step 1. Prepare the leather and put it on the laser cutting table.

Step 2. Import your design file of leather into laser engraving software, and set laser parameters like speed and power.

(After you buy the machine, our laser expert will recommend suitable parameters to you in terms of your engraving requirements and materials.)

Step 3. Press the start button, and the laser machine starts cutting and engraving.

If you have any questions about laser etching leather, talk with us!

If you are interested in the leather laser etching machine, go on the recommendation ⇨

How to select a suitable leather laser etching machine?

Related News

Laser engraved leather is the new fashion in leather projects!

Intricate engraved details, flexible and customized pattern engraving, and super fast engraving speed definitely surprise you!

Only need one laser engraver machine, no need for any dies, no need for knife bits, the leather engraving process can be realized at a fast speed.

Therefore, laser engraving leather not only greatly increases productivity for leather products manufacturing, but also is a flexible DIY tool to meet all kinds of creative ideas for hobbyists.

Laser cut woodworking has gained popularity across various industries, from crafts and ornaments to architectural models, furniture, and more.

Thanks to its cost-effective customization, highly precise cutting and engraving capabilities, and compatibility with a wide range of wood materials, woodworking laser cutting machines are ideal for creating detailed wood designs through cutting, engraving, and marking.

Whether you’re a hobbyist or a professional woodworker, these machines offer unmatched convenience.

Lucite is a popular material widely used in both daily life and industrial applications.

While most people are familiar with acrylic, plexiglass, and PMMA, Lucite stands out as a type of high-quality acrylic.

There are various grades of acrylic, differentiated by clarity, strength, scratch resistance, and appearance.

As a higher-quality acrylic, Lucite often comes with a higher price tag.

Given that lasers can cut acrylic and plexiglass, you might wonder: can you laser cut Lucite?

Let's dive in to find out more.

Get One Laser Etching Machine for Your Leather Business or Design?

Post time: Sep-19-2024